Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 7.98 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

Automotive Die-Stamping Equipment Market Analysis Report 2023-2032:

The Automotive Die-Stamping Equipment Market is poised to experience substantial growth, with an estimated CAGR of 5.25% between 2022 and 2032. The market size is forecasted to expand by USD 9,865.89 million during this period. The growth of the market hinges on several key factors, including the increasing demand for automobiles worldwide, advancements in automotive technology, and the growing need for lightweight and durable components in vehicles. Automotive die-stamping equipment is a crucial element in the manufacturing process of automotive parts and components, enabling the mass production of precise and high-quality metal parts used in vehicles.

Automotive Die-Stamping Equipment Market Overview:

Drivers:

One of the primary drivers fueling the growth of the automotive die-stamping equipment market is the rising demand for automobiles across the globe. As the global population continues to increase, there is a parallel increase in the need for efficient and reliable transportation solutions. This, in turn, drives the automotive manufacturing industry, leading to higher demand for die-stamped components like body panels, chassis parts, and structural components.

Furthermore, advancements in automotive technology, including the development of electric and autonomous vehicles, are contributing to the growth of this market. Electric vehicles, in particular, require specialized die-stamped components to accommodate their unique design and requirements. The shift towards lightweighting and improved fuel efficiency also necessitates the use of advanced die-stamping equipment to manufacture lightweight yet strong automotive parts.

Trends:

A noteworthy trend shaping the automotive die-stamping equipment market is the integration of automation and robotics in the die-stamping process. Automation not only enhances production efficiency but also ensures higher precision and consistency in stamped components. Robots are increasingly being employed for tasks such as loading and unloading materials, tool changes, and quality control inspections, making the manufacturing process more efficient and cost-effective.

Additionally, there is a growing emphasis on sustainability and eco-friendly manufacturing practices in the automotive industry. This has led to the adoption of eco-friendly materials and processes in die-stamping, further driving the demand for modern die-stamping equipment that can handle these materials.

Restraints:

The automotive die-stamping equipment market faces challenges related to the complexity of manufacturing processes and the potential for defects in stamped components. The precision required in die-stamping demands a controlled manufacturing environment, and any deviations or defects can result in the rejection of parts and increased production costs. This necessitates strict quality control measures and skilled labor, which can be limiting factors for market growth.

Moreover, the automotive industry's shift towards electric vehicles and the use of alternative materials like composites pose challenges for traditional die-stamping processes. Adapting die-stamping equipment to work with these materials requires innovation and investment, which can hinder market growth in the short term.

Automotive Die-Stamping Equipment Market Segmentation By Application:

The automotive body components segment is expected to witness significant growth in the forecast period. Die-stamped body components, such as doors, hoods, and fenders, are essential for the structural integrity and aesthetics of automobiles. As automotive design trends lean towards sleek and aerodynamic profiles, the demand for precisely stamped body components is on the rise.

Additionally, safety and crashworthiness standards in the automotive industry necessitate the use of high-strength materials for body components. This further underscores the importance of advanced die-stamping equipment that can handle these materials efficiently.

Automotive Die-Stamping Equipment Market Segmentation By Type:

The hydraulic die-stamping equipment segment is poised for growth due to its versatility and capability to handle a wide range of materials and part sizes. Hydraulic die-stamping presses offer high tonnage capacities and are suitable for stamping heavy-duty automotive components.

The market for servo-driven die-stamping equipment is also on the rise, driven by the need for precision and energy efficiency. Servo-driven presses provide better control over the stamping process, resulting in improved part quality and reduced energy consumption, making them an attractive option for manufacturers aiming to meet sustainability goals.

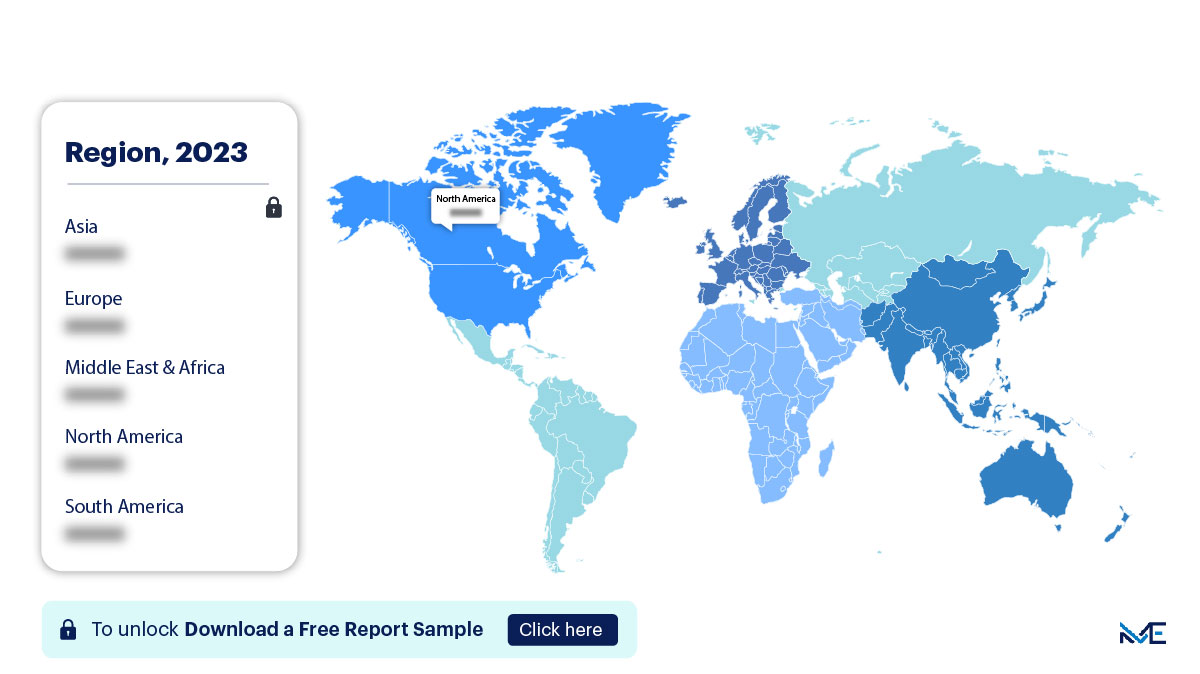

Regional Overview:

Download the report summary now!

Request pdf Sample

North America is expected to make a significant contribution to the global market during the forecast period. The presence of well-established automotive manufacturers in the region, such as General Motors, Ford, and Chrysler, drives the demand for die-stamped components. Additionally, the growing interest in electric vehicles and the need for lightweighting in vehicle design further boost the market for advanced die-stamping equipment in North America.

Europe, with its strong automotive industry and stringent safety and emissions standards, is also a key market for automotive die-stamping equipment. The region's emphasis on vehicle safety and design precision necessitates the use of advanced die-stamping technology.

Automotive Die-Stamping Equipment Market Customer Landscape:

The automotive die-stamping equipment market report includes an analysis of the adoption lifecycle, from innovators to laggards, and evaluates adoption rates in different regions based on market penetration. It also outlines key purchase criteria and factors influencing price sensitivity to assist companies in shaping their growth strategies.

Major Companies in the Automotive Die-Stamping Equipment Market:

Companies operating in the automotive die-stamping equipment market are implementing various strategies to enhance their market presence. These strategies include strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches. Some notable companies in the market include:

- AIDA Engineering Ltd.

- Amada Co., Ltd.

- Schuler AG

- Komatsu Ltd.

- Jier Machine Tool Group Co., Ltd.

- Yamada Dobby Co., Ltd.

- Mitsubishi Heavy Industries, Ltd.

- Hefei Metalforming Intelligent Manufacturing Co., Ltd.

- Nidec Minster Corporation

- JFY Group

- ABB Ltd.

- KUKA AG

- Fagor Arrasate S.Coop.

- Danobat Group

- AP&T AB

- Isgec Heavy Engineering Ltd.

- Eagle Press & Equipment Co., Ltd.

- Simpac Inc.

- Chin Fong Machine Industrial Co., Ltd.

- Schuler India Pvt. Ltd.

Segment Overview:

The automotive die-stamping equipment market report forecasts market growth by revenue at global, regional, and country levels. It also provides an analysis of the latest trends and growth opportunities from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032):

- Body Components

- Chassis Parts

- Engine Components

- Others

- Type Outlook (USD Million, 2019 - 2032):

- Hydraulic Die-Stamping Equipment

- Servo-Driven Die-Stamping Equipment

- Geography Outlook (USD Million, 2019 - 2032):

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Brazil

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Table of Contents

Chapter 1 Overview of Automotive Die-stamping Equipment

1.1 Definition of Automotive Die-stamping Equipment in This Report

1.2 Commercial Types of Automotive Die-stamping Equipment

1.2.1 Automotive OE manufacturers

1.2.2 Independent stamp presses

1.3 Downstream Application of Automotive Die-stamping Equipment

1.3.1 Passenger car

1.3.2 Commercial vehicle

1.4 Development History of Automotive Die-stamping Equipment

1.5 Market Status and Trend of Automotive Die-stamping Equipment 2013-2023

1.5.1 Global Automotive Die-stamping Equipment Market Status and Trend 2013-2023

1.5.2 Regional Automotive Die-stamping Equipment Market Status and Trend 2013-2023

Chapter 2 Global Market Status and Forecast by Regions

2.1 Market Development of Automotive Die-stamping Equipment 2013-2017

2.2 Production Market of Automotive Die-stamping Equipment by Regions

2.2.1 Production Volume of Automotive Die-stamping Equipment by Regions

2.2.2 Production Value of Automotive Die-stamping Equipment by Regions

2.3 Demand Market of Automotive Die-stamping Equipment by Regions

2.4 Production and Demand Status of Automotive Die-stamping Equipment by Regions

2.4.1 Production and Demand Status of Automotive Die-stamping Equipment by Regions 2013-2017

2.4.2 Import and Export Status of Automotive Die-stamping Equipment by Regions 2013-2017

Chapter 3 Global Market Status and Forecast by Types

3.1 Production Volume of Automotive Die-stamping Equipment by Types

3.2 Production Value of Automotive Die-stamping Equipment by Types

3.3 Market Forecast of Automotive Die-stamping Equipment by Types

Chapter 4 Global Market Status and Forecast by Downstream Industry

4.1 Demand Volume of Automotive Die-stamping Equipment by Downstream Industry

4.2 Market Forecast of Automotive Die-stamping Equipment by Downstream Industry

Chapter 5 Market Driving Factor Analysis of Automotive Die-stamping Equipment

5.1 Global Economy Situation and Trend Overview

5.2 Automotive Die-stamping Equipment Downstream Industry Situation and Trend Overview

Chapter 6 Automotive Die-stamping Equipment Market Competition Status by Major Manufacturers

6.1 Production Volume of Automotive Die-stamping Equipment by Major Manufacturers

6.2 Production Value of Automotive Die-stamping Equipment by Major Manufacturers

6.3 Basic Information of Automotive Die-stamping Equipment by Major Manufacturers

6.3.1 Headquarters Location and Established Time of Automotive Die-stamping Equipment Major Manufacturer

6.3.2 Employees and Revenue Level of Automotive Die-stamping Equipment Major Manufacturer

6.4 Market Competition News and Trend

6.4.1 Merger, Consolidation or Acquisition News

6.4.2 Investment or Disinvestment News

6.4.3 New Product Development and Launch

Chapter 7 Automotive Die-stamping Equipment Major Manufacturers Introduction and Market Data

7.1 Fagor Arrasate

7.1.1 Company profile

7.1.2 Representative Automotive Die-stamping Equipment Product

7.1.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Fagor Arrasate

7.2 Komatsu

7.2.1 Company profile

7.2.2 Representative Automotive Die-stamping Equipment Product

7.2.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Komatsu

7.3 Macrodyne Technologies

7.3.1 Company profile

7.3.2 Representative Automotive Die-stamping Equipment Product

7.3.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Macrodyne Technologies

7.4 Schuler

7.4.1 Company profile

7.4.2 Representative Automotive Die-stamping Equipment Product

7.4.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Schuler

7.5 Velodyne LiDAR (the U.S.)

7.5.1 Company profile

7.5.2 Representative Automotive Die-stamping Equipment Product

7.5.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Velodyne LiDAR (the U.S.)

7.6 Magna International Inc. (Canada)

7.6.1 Company profile

7.6.2 Representative Automotive Die-stamping Equipment Product

7.6.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Magna International Inc. (Canada)

7.7 LeddarTech (Canada)

7.7.1 Company profile

7.7.2 Representative Automotive Die-stamping Equipment Product

7.7.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of LeddarTech (Canada)

7.8 NVIDIA Corporation (the U.S.)

7.8.1 Company profile

7.8.2 Representative Automotive Die-stamping Equipment Product

7.8.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of NVIDIA Corporation (the U.S.)

7.9 Robert Bosch GmbH (Germany)

7.9.1 Company profile

7.9.2 Representative Automotive Die-stamping Equipment Product

7.9.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Robert Bosch GmbH (Germany)

7.10 Continental AG (Germany)

7.10.1 Company profile

7.10.2 Representative Automotive Die-stamping Equipment Product

7.10.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Continental AG (Germany)

7.11 Delphi Automotive PLC (the U.K)

7.11.1 Company profile

7.11.2 Representative Automotive Die-stamping Equipment Product

7.11.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Delphi Automotive PLC (the U.K)

7.12 Denso Corporation (Japan)

7.12.1 Company profile

7.12.2 Representative Automotive Die-stamping Equipment Product

7.12.3 Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Denso Corporation (Japan)

Chapter 8 Upstream and Downstream Market Analysis of Automotive Die-stamping Equipment

8.1 Industry Chain of Automotive Die-stamping Equipment

8.2 Upstream Market and Representative Companies Analysis

8.3 Downstream Market and Representative Companies Analysis

Chapter 9 Cost and Gross Margin Analysis of Automotive Die-stamping Equipment

9.1 Cost Structure Analysis of Automotive Die-stamping Equipment

9.2 Raw Materials Cost Analysis of Automotive Die-stamping Equipment

9.3 Labor Cost Analysis of Automotive Die-stamping Equipment

9.4 Manufacturing Expenses Analysis of Automotive Die-stamping Equipment

Chapter 10 Marketing Status Analysis of Automotive Die-stamping Equipment

10.1 Marketing Channel

10.1.1 Direct Marketing

10.1.2 Indirect Marketing

10.1.3 Marketing Channel Development Trend

10.2 Market Positioning

10.2.1 Pricing Strategy

10.2.2 Brand Strategy

10.2.3 Target Client

10.3 Distributors/Traders List

Chapter 11 Report Conclusion

Chapter 12 Research Methodology and Reference

12.1 Methodology/Research Approach

12.1.1 Research Programs/Design

12.1.2 Market Size Estimation

12.1.3 Market Breakdown and Data Triangulation

12.2 Data Source

12.2.1 Secondary Sources

12.2.2 Primary Sources

12.3 Reference

List of Tables

Table Advantage and Disadvantage of Automotive OE manufacturers

Table Advantage and Disadvantage of Independent stamp presses

Table Production Volume of Automotive Die-stamping Equipment by Regions 2013-2017

Table Production Value of Automotive Die-stamping Equipment by Regions 2013-2017

Table Demand Volume of Automotive Die-stamping Equipment by Regions 2013-2017

Table Production and Demand Status of Automotive Die-stamping Equipment in Region One 2013-2017

Table Production and Demand Status of Automotive Die-stamping Equipment in Region Two 2013-2017

Table Production and Demand Status of Automotive Die-stamping Equipment in Region Three 2013-2017

Table Production and Demand Status of Automotive Die-stamping Equipment in Region Four 2013-2017

Table Import Volume of Automotive Die-stamping Equipment by Regions 2013-2017

Table Export Volume of Automotive Die-stamping Equipment by Regions 2013-2017

Table Production Volume of Automotive Die-stamping Equipment by Types 2013-2017

Table Production Value of Automotive Die-stamping Equipment by Types 2013-2017

Table Production Volume Forecast of Automotive Die-stamping Equipment by Types 2018-2023

Table Production Value Forecast of Automotive Die-stamping Equipment by Types 2018-2023

Table Demand Volume of Automotive Die-stamping Equipment by Downstream Industry 2013-2017

Table Demand Volume Forecast of Automotive Die-stamping Equipment by Downstream Industry 2018-2023

Table Production Volume of Automotive Die-stamping Equipment by Major Manufacturers 2013-2017

Table Production Value of Automotive Die-stamping Equipment by Major Manufacturers 2013-2017

Table Headquarters Location and Established Time of Automotive Die-stamping Equipment Major Manufacturer

Table Employees and Revenue Level of Automotive Die-stamping Equipment Major Manufacturer

Table Representative Automotive Die-stamping Equipment Product One of Fagor Arrasate

Table Representative Automotive Die-stamping Equipment Product Two of Fagor Arrasate

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Fagor Arrasate 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Komatsu

Table Representative Automotive Die-stamping Equipment Product Two of Komatsu

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Komatsu 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Macrodyne Technologies

Table Representative Automotive Die-stamping Equipment Product Two of Macrodyne Technologies

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Macrodyne Technologies 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Schuler

Table Representative Automotive Die-stamping Equipment Product Two of Schuler

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Schuler 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Velodyne LiDAR (the U.S.)

Table Representative Automotive Die-stamping Equipment Product Two of Velodyne LiDAR (the U.S.)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Velodyne LiDAR (the U.S.) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Magna International Inc. (Canada)

Table Representative Automotive Die-stamping Equipment Product Two of Magna International Inc. (Canada)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Magna International Inc. (Canada) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of LeddarTech (Canada)

Table Representative Automotive Die-stamping Equipment Product Two of LeddarTech (Canada)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of LeddarTech (Canada) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of NVIDIA Corporation (the U.S.)

Table Representative Automotive Die-stamping Equipment Product Two of NVIDIA Corporation (the U.S.)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of NVIDIA Corporation (the U.S.) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Robert Bosch GmbH (Germany)

Table Representative Automotive Die-stamping Equipment Product Two of Robert Bosch GmbH (Germany)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Robert Bosch GmbH (Germany) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Continental AG (Germany)

Table Representative Automotive Die-stamping Equipment Product Two of Continental AG (Germany)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Continental AG (Germany) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Delphi Automotive PLC (the U.K)

Table Representative Automotive Die-stamping Equipment Product Two of Delphi Automotive PLC (the U.K)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Delphi Automotive PLC (the U.K) 2013-2017

Table Representative Automotive Die-stamping Equipment Product One of Denso Corporation (Japan)

Table Representative Automotive Die-stamping Equipment Product Two of Denso Corporation (Japan)

Table Automotive Die-stamping Equipment Sales, Revenue, Price and Gross Margin of Denso Corporation (Japan) 2013-2017

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"