Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 8.61 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

US Automotive Parts Magnesium Die Casting Market Analysis Report 2023-2032

The US Automotive Parts Magnesium Die Casting Market is poised to experience a Compound Annual Growth Rate (CAGR) of 6.92% between 2022 and 2032. Over this period, the market size is expected to witness a significant increase of USD 1,865.40 million. The growth of this market is driven by several factors, including the demand for lightweight materials, the automotive industry's shift towards fuel efficiency, and the advantages of magnesium in die casting applications. The market comprises services dedicated to producing automotive components using magnesium die casting, aiming for cost-efficiency and reduced environmental impact.

US Automotive Parts Magnesium Die Casting Market Overview

Drivers

A key driver behind the expansion of the US Automotive Parts Magnesium Die Casting Market is the automotive industry's relentless pursuit of lightweight materials. As vehicles become more fuel-efficient and eco-friendly, the use of lightweight materials like magnesium in die casting gains prominence. Magnesium's high strength-to-weight ratio and excellent castability make it an ideal choice for producing lightweight automotive components.

Furthermore, stringent regulations regarding emissions and fuel efficiency are significantly driving market growth. As automakers strive to meet these regulations, they are increasingly turning to magnesium die casting to reduce vehicle weight and improve fuel economy.

Trends

An important trend shaping the US Automotive Parts Magnesium Die Casting Market is the adoption of innovative technologies for magnesium die casting. Advanced casting processes and computer-aided design (CAD) software are enhancing the efficiency and precision of magnesium die casting. These technologies contribute to the production of high-quality automotive components with complex geometries.

Additionally, sustainability and recyclability are influencing market dynamics. Magnesium is a highly recyclable material, and the industry is focusing on closed-loop systems to minimize waste and environmental impact.

Restraints

One of the challenges faced by the US Automotive Parts Magnesium Die Casting Market is the cost of raw materials and production. While magnesium offers significant benefits, it is more expensive than some other materials. Reducing production costs while maintaining quality is a challenge that the industry must address.

Moreover, the complex nature of die casting operations and the need for skilled labor can pose challenges for market players. Ensuring consistent product quality and minimizing defects are crucial but may require ongoing training and quality control measures.

US Automotive Parts Magnesium Die Casting Market Segmentation By Application

The market segments by application include engine parts, transmission components, structural parts, and others. Engine parts and transmission components are expected to remain prominent growth segments within the US Automotive Parts Magnesium Die Casting Market. These components often require high precision and benefit from the lightweight and durable properties of magnesium.

Structural parts, including chassis and body components, are also gaining importance as automakers seek to reduce vehicle weight and improve safety and fuel efficiency.

US Automotive Parts Magnesium Die Casting Market Segmentation By Casting Process

The market can be segmented by casting process into high-pressure die casting (HPDC), low-pressure die casting (LPDC), and gravity die casting. High-pressure die casting is projected to experience significant growth during the forecast period. It is a highly efficient process for producing complex and precise magnesium components.

Low-pressure die casting and gravity die casting are also relevant for specific applications, offering different advantages in terms of cost and production flexibility.

Download the report summary now!

Request pdf SampleThe United States is anticipated to be the key driver of the US Automotive Parts Magnesium Die Casting Market. The country's robust automotive industry, combined with the demand for lightweight materials and fuel-efficient vehicles, creates a conducive environment for market growth.

The market experienced fluctuations during the COVID-19 pandemic as immediate health and economic challenges took precedence. However, as the automotive industry resumes focus on fuel efficiency and eco-friendly solutions, the market is poised to regain momentum in the post-pandemic era.

US Automotive Parts Magnesium Die Casting Market Customer Landscape

The US Automotive Parts Magnesium Die Casting Market report offers insights into the adoption patterns of the market, ranging from early adopters to laggards. The report examines adoption rates across different regions based on penetration levels. Moreover, the report delves into key criteria influencing purchase decisions and factors affecting price sensitivity. These insights assist companies in formulating effective strategies for market entry and growth.

Major US Automotive Parts Magnesium Die Casting Market Companies

Prominent players in the US Automotive Parts Magnesium Die Casting Market are implementing diverse strategies to bolster their market presence. These strategies include advanced casting technologies, research and development for cost reduction, and the exploration of new applications for magnesium die casting in the automotive sector.

Sample list of major companies in the market:

- MgTech Inc.

- Precision Castparts Corp.

- Meridian Lightweight Technologies

- Nemak

- Georg Fischer AG

Qualitative and quantitative analyses of these companies offer valuable insights into the competitive landscape. This analysis enables stakeholders to comprehend market dynamics and assess the strengths and weaknesses of key players.

Segment Overview

The US Automotive Parts Magnesium Die Casting Market report provides revenue forecasts on a regional and product-specific level. The report also includes an analysis of emerging trends and growth opportunities spanning from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032)

- Engine Parts

- Transmission Components

- Structural Parts

- Others

- Casting Process Outlook (USD Million, 2019 - 2032)

- High-Pressure Die Casting (HPDC)

- Low-Pressure Die Casting (LPDC)

- Gravity Die Casting

- Geography Outlook (USD Million, 2019 - 2032)

- North America

- United States

- Canada

- Europe

- United Kingdom

- Germany

- France

- Rest of Europe

- APAC

- China

- Japan

- India

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- United Arab Emirates

- South Africa

- Rest of Middle East & Africa

TABLE OF CONTENTS: GLOBAL US Automotive Parts Magnesium Die Casting MARKET

Chapter 1. MARKET SYNOPSIS

1.1. Market Definition

1.2. Research Scope & Premise

1.3. Methodology

1.4. Market Estimation Technique

Chapter 2. EXECUTIVE SUMMARY

2.1. Summary Snapshot, 2016 – 2027

Chapter 3. INDICATIVE METRICS

3.1. Macro Indicators

Chapter 4. US Automotive Parts Magnesium Die Casting MARKET SEGMENTATION & IMPACT ANALYSIS

4.1. US Automotive Parts Magnesium Die Casting Segmentation Analysis

4.2. Industrial Outlook

4.3. Price Trend Analysis

4.4. Regulatory Framework

4.5. Porter’s Five Forces Analysis

4.5.1. Power Of Suppliers

4.5.2. Power Of Buyers

4.5.3. Threat Of Substitutes

4.5.4. Threat Of New Entrants

4.5.5. Competitive Rivalry

Chapter 5. US Automotive Parts Magnesium Die Casting MARKET BY Production process type landscape

SIGHTS & TRENDS

5.1. Segment 1 Dynamics & Market Share, 2019 & 2027

5.2 Pressure Die Casting

5.2.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

5.2.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

5.3 Vacuum Die Casting

5.3.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

5.3.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

5.4 Squeeze Die Casting

5.4.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

5.4.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

5.5 Semi-Solid Die Casting

5.5.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

5.5.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

Chapter 6. US Automotive Parts Magnesium Die Casting MARKET BY Application type INSIGHTS & TRENDS

6.1. Segment 2 Dynamics & Market Share, 2019 & 2027

6.2 Engine Parts

6.2.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

6.2.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

6.3 Transmission Components

6.3.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

6.3.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

6.4 Body Parts

6.4.1. Market Estimates And Forecast, 2016 – 2027 (USD Million)

6.4.2. Market Estimates And Forecast, By Region, 2016 – 2027 (USD Million)

Chapter 7. US Automotive Parts Magnesium Die Casting MARKET REGIONAL OUTLOOK

7.1. US Automotive Parts Magnesium Die Casting Market Share By Region, 2019 & 2027

7.2. NORTH AMERICA

7.2.1. North America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.2.2. North America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.2.3. North America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.2.4. North America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.2.5. U.S.

7.2.5.1. U.S. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.2.5.2. U.S. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.2.5.3. U.S. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.2.5.4. U.S. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.2.6. CANADA

7.2.6.1. Canada US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.2.6.2. Canada US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.2.6.3. Canada US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.2.6.4. Canada US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.3. EUROPE

7.3.1. Europe US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.3.2. Europe US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.3.3. Europe US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.3.4. Europe US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.3.5. GERMANY

7.3.5.1. Germany US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.3.5.2. Germany US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.3.5.3. Germany US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.3.5.4. Germany US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.3.6. FRANCE

7.3.6.1. France US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.3.6.2. France US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.3.6.3. France US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.3.6.4. France US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.3.7. U.K.

7.3.7.1. U.K. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.3.7.2. U.K. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.3.7.3. U.K. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.3.7.4. U.K. US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.4. ASIA-PACIFIC

7.4.1. Asia Pacific US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.4.2. Asia Pacific US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.4.3. Asia Pacific US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.4.4. Asia Pacific US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.4.5. CHINA

7.4.5.1. China US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.4.5.2. China US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.4.5.3. China US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.4.5.4. China US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.4.6. INDIA

7.4.6.1. India US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.4.6.2. India US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.4.6.3. India US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.4.6.4. India US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.4.7. JAPAN

7.4.7.1. Japan US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.4.7.2. Japan US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.4.7.3. Japan US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.4.7.4. Japan US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.4.8. AUSTRALIA

7.4.8.1. Australia US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.4.8.2. Australia US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.4.8.3. Australia US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.4.8.4. Australia US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.5. MIDDLE EAST AND AFRICA (MEA)

7.5.1. Mea US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.5.2. Mea US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.5.3. Mea US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.5.4. Mea US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

7.6. LATIN AMERICA

7.6.1. Latin America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast, 2016 – 2027, (USD Million)

7.6.2. Latin America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 1, 2016 –2027, (USD Million)

7.6.3. Latin America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 2, 2016 –2027, (USD Million)

7.6.4. Latin America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Production Process, 2016 –2027, (USD Million)

7.6.5. Latin America US Automotive Parts Magnesium Die Casting Market Estimates And Forecast By Segment 3, 2016 –2027, (USD Million)

Chapter 8. COMPETITIVE LANDSCAPE

8.1. Market Share By Manufacturers

8.2. Strategic Benchmarking

8.2.1. New Product Launches

8.2.2. Investment & Expansion

8.2.3. Acquisitions

8.2.4. Partnerships, Agreement, Mergers, Joint-Ventures

8.3. Vendor Landscape

8.3.1. North American Suppliers

8.3.2. European Suppliers

8.3.3. Asia-Pacific Suppliers

8.3.4. Rest Of The World Suppliers

Chapter 9. COMPANY PROFILES

9.1 Meridian Lightweight Technology

9.1.1. Company Overview

9.1.2. Financial Performance

9.1.3. Product Insights

9.1.4. Strategic Initiatives

9.2 George Fischer AG

9.2.1. Company Overview

9.2.2. Financial Performance

9.2.3. Product Insights

9.2.4. Strategic Initiatives

9.3 Shiloh Industries

9.3.1. Company Overview

9.3.2. Financial Performance

9.3.3. Product Insights

9.3.4. Strategic Initiatives

9.4 Pace Industries

9.4.1. Company Overview

9.4.2. Financial Performance

9.4.3. Product Insights

9.4.4. Strategic Initiatives

9.5 Gibbs Die Casting Group

9.5.1. Company Overview

9.5.2. Financial Performance

9.5.3. Product Insights

9.5.4. Strategic Initiatives

9.6 Company 6

9.6.1. Company Overview

9.6.2. Financial Performance

9.6.3. Product Insights

9.6.4. Strategic Initiatives

9.7 Company 7

9.7.1. Company Overview

9.7.2. Financial Performance

9.7.3. Product Insights

9.7.4. Strategic Initiatives

9.8 Company 8

9.8.1. Company Overview

9.8.2. Financial Performance

9.8.3. Product Insights

9.8.4. Strategic Initiatives

9.9 Company 9

9.9.1. Company Overview

9.9.2. Financial Performance

9.9.3. Product Insights

9.9.4. Strategic Initiatives

9.10 Company 10

9.10.1. Company Overview

9.10.2. Financial Performance

9.10.3. Product Insights

9.10.4. Strategic Initiatives

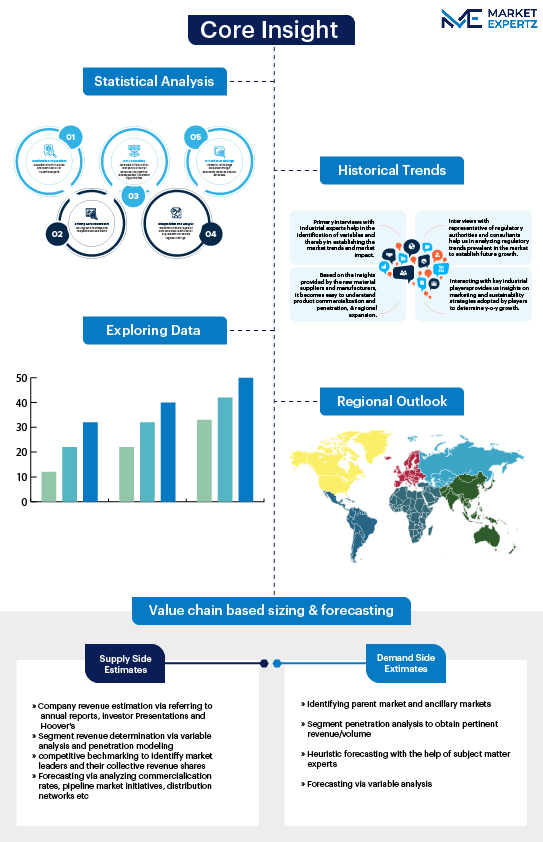

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"