Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 6.06 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The DBC Ceramic Substrate Market size is estimated to grow at a CAGR of 6.78% between 2022 and 2032. The market size is forecast to increase by USD 1,245.32 million. The growth of the market depends on several factors, including the increasing demand for power electronics devices, the growing adoption of electric vehicles, and the rising need for efficient thermal management solutions. DBC (Direct Bonded Copper) ceramic substrate is a key component used in power electronic devices to provide electrical insulation and efficient heat dissipation. It consists of a ceramic layer, typically made of aluminum oxide (Al2O3) or aluminum nitride (AlN), bonded with a copper layer. This combination of materials allows for high thermal conductivity and electrical insulation, making DBC ceramic substrates ideal for applications that require efficient heat dissipation and reliable electrical performance.

DBC Ceramic Substrate Market Overview:

Drivers:

One of the key factors driving the DBC ceramic substrate market growth is the increasing demand for power electronics devices. Power electronics devices, such as inverters, converters, and power modules, are widely used in various industries, including automotive, renewable energy, consumer electronics, and industrial automation. These devices require efficient thermal management solutions to ensure reliable performance and prevent overheating. DBC ceramic substrates offer excellent thermal conductivity and electrical insulation properties, making them an ideal choice for power electronics applications. The growing adoption of electric vehicles and the increasing demand for renewable energy sources are further fueling the demand for power electronics devices, thereby driving the market growth of DBC ceramic substrates.

Moreover, the rising need for efficient thermal management solutions is another driver for the DBC ceramic substrate market. As electronic devices become smaller and more powerful, managing heat dissipation becomes crucial to ensure their reliable operation. DBC ceramic substrates, with their high thermal conductivity and low thermal resistance, help in dissipating heat effectively, thereby improving the overall performance and reliability of electronic devices. The increasing demand for high-power density applications, such as data centers, electric vehicles, and industrial machinery, is driving the need for efficient thermal management solutions, thus boosting the market growth of DBC ceramic substrates.

Trends:

A key trend shaping the DBC ceramic substrate market growth is the increasing adoption of wide-bandgap semiconductors. Wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), offer superior performance compared to traditional silicon-based semiconductors. They can operate at higher temperatures, handle higher voltages, and switch faster, making them ideal for high-power and high-frequency applications. However, wide-bandgap semiconductors generate more heat, requiring efficient thermal management solutions. DBC ceramic substrates, with their excellent thermal conductivity and electrical insulation properties, are well-suited for wide-bandgap semiconductor devices. The increasing adoption of wide-bandgap semiconductors in applications such as electric vehicles, renewable energy systems, and power electronics is driving the demand for DBC ceramic substrates.

Restraints:

One of the key challenges hindering the DBC ceramic substrate market growth is the high cost of production. DBC ceramic substrates require specialized manufacturing processes, including the bonding of ceramic and copper layers, precision machining, and surface finishing. These processes involve high capital investment and require skilled labor, leading to higher production costs. The high cost of DBC ceramic substrates can limit their adoption, especially in price-sensitive markets. Manufacturers need to find ways to optimize production processes and reduce costs to make DBC ceramic substrates more affordable and accessible to a wider range of applications.

Furthermore, the availability of alternative materials and technologies is another restraint for the DBC ceramic substrate market. Other types of ceramic substrates, such as thick film ceramic substrates and LTCC (Low-Temperature Co-fired Ceramic) substrates, offer similar thermal management capabilities at a lower cost. Additionally, emerging technologies, such as direct liquid cooling and advanced heat pipe solutions, provide alternative approaches to thermal management. These alternative materials and technologies pose a competitive challenge to DBC ceramic substrates, requiring manufacturers to differentiate their products and demonstrate their unique advantages to gain market share.

DBC Ceramic Substrate Market Segmentation By Application:

The power electronics segment is estimated to witness significant growth during the forecast period. DBC ceramic substrates play a critical role in power electronic devices, providing electrical insulation and efficient heat dissipation. Power electronics devices, such as inverters, converters, and power modules, are used in various applications, including automotive, renewable energy, consumer electronics, and industrial automation. These devices require reliable thermal management solutions to ensure optimal performance and prevent overheating. DBC ceramic substrates, with their high thermal conductivity and electrical insulation properties, offer an ideal solution for power electronics applications. The increasing demand for power electronics devices, driven by the adoption of electric vehicles and the growth of renewable energy systems, is expected to fuel the demand for DBC ceramic substrates in the power electronics segment.

The power electronics segment was the largest segment and was valued at USD 450.23 million in 2022. The automotive industry is one of the key drivers for the growth of the power electronics segment. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) require efficient power electronics systems to manage energy conversion and control. DBC ceramic substrates, with their high thermal conductivity and electrical insulation properties, are widely used in EV power modules, inverters, and converters. The increasing adoption of EVs and the growing focus on reducing carbon emissions are driving the demand for power electronics devices in the automotive industry, thereby boosting the market growth of DBC ceramic substrates in the power electronics segment.

DBC Ceramic Substrate Market Segmentation By Type:

The aluminum oxide (Al2O3) segment is estimated to dominate the DBC ceramic substrate market during the forecast period. Aluminum oxide is a widely used ceramic material due to its excellent electrical insulation and thermal conductivity properties. DBC ceramic substrates made of aluminum oxide offer high reliability and performance, making them suitable for a wide range of applications. The automotive, consumer electronics, and industrial sectors are the major end-users of DBC ceramic substrates made of aluminum oxide. The increasing demand for power electronics devices in these industries, coupled with the need for efficient thermal management solutions, is driving the market growth of aluminum oxide-based DBC ceramic substrates.

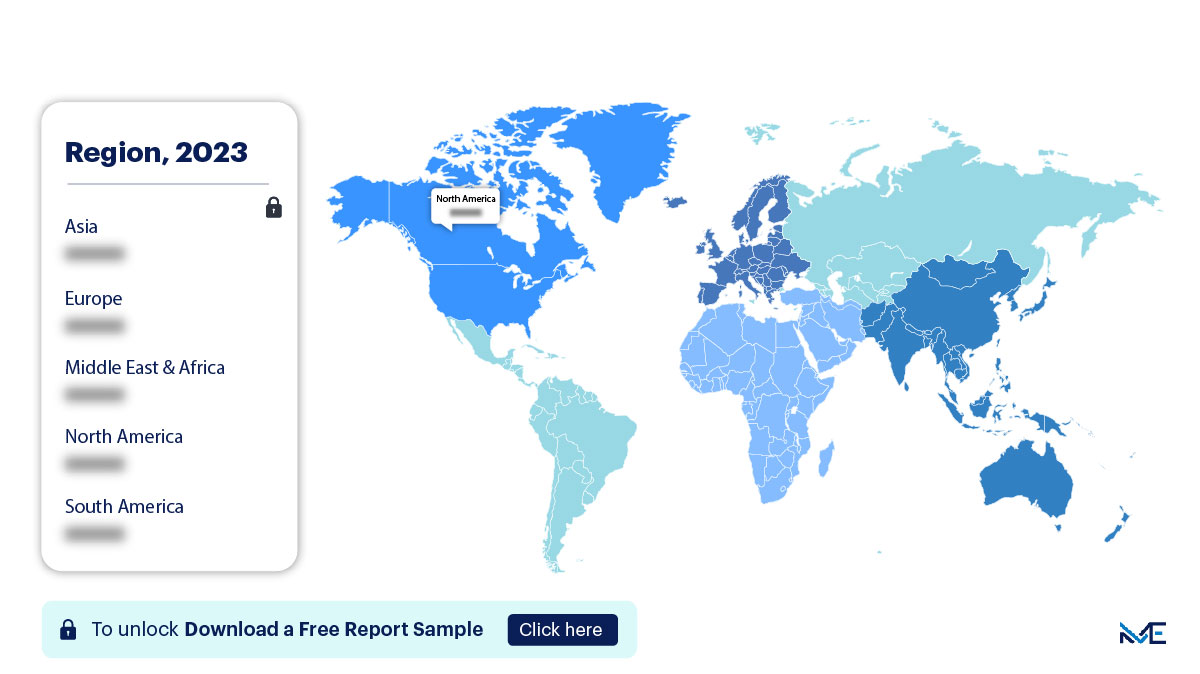

Regional Overview:

Download the report summary now!

Request pdf Sample

APAC is estimated to contribute 55% to the growth of the global DBC ceramic substrate market during the forecast period. The region is a major hub for electronics manufacturing, with countries like China, Japan, South Korea, and Taiwan being key players in the industry. The increasing demand for consumer electronics, automotive electronics, and industrial automation systems in APAC is driving the market growth of DBC ceramic substrates. The region is witnessing significant investments in electric vehicles and renewable energy systems, which further fuel the demand for power electronics devices and, in turn, DBC ceramic substrates. The presence of major semiconductor manufacturers and electronics companies in APAC, along with favorable government initiatives and policies, supports the growth of the DBC ceramic substrate market in the region.

In 2020, during the COVID-19 pandemic, the global DBC ceramic substrate market witnessed a temporary slowdown due to disruptions in the supply chain and manufacturing operations. However, with the gradual recovery of the global economy and the resumption of manufacturing activities, the market is expected to regain momentum. The increasing focus on digitalization, the growing adoption of remote work and online learning, and the rising demand for healthcare equipment are expected to drive the demand for power electronics devices and, consequently, DBC ceramic substrates in the post-pandemic period.

DBC Ceramic Substrate Market Customer Landscape:

The DBC ceramic substrate market industry report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their growth strategies.

Who are the Major DBC Ceramic Substrate Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Rogers Corporation: A global leader in engineered materials, Rogers Corporation offers DBC ceramic substrates under their Power Electronics Solutions segment. Their substrates are widely used in power modules for applications like electric vehicles, industrial automation, and renewable energy.

Kyocera Corporation: Known for its diverse range of advanced ceramic products, Kyocera manufactures DBC ceramic substrates that find applications in power semiconductor modules, contributing to efficient heat management and electrical insulation.

Mitsubishi Materials Corporation: This company provides DBC ceramic substrates designed for high-power applications, particularly in the fields of automotive electronics, industrial machinery, and renewable energy systems.

The competitive landscape section in the report comprehensively analyzes 15 market-leading companies, including:

- Rogers Corporation

- Kyocera Corporation

- Mitsubishi Materials Corporation

- CeramTec

- Heraeus Holding GmbH

- Infineon Technologies AG

- Shenzhen Sunyuan Technology Co., Ltd.

- DuPont

- Ferro Corporation

- Taiyo Yuden Co., Ltd.

- Murata Manufacturing Co., Ltd.

- Tong Hsing Electronic Industries, Ltd.

- NTK Technologies, Inc.

- KCC Corporation

- NGK Insulators, Ltd.

Segment Overview:

The DBC ceramic substrate market report presents revenue growth forecasts at global, regional, and country levels, accompanied by insights into evolving trends and opportunities from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032):

- Electric Vehicles

- Industrial Equipment

- Renewable Energy

- Consumer Electronics

- Others

- Type Outlook (USD Million, 2019 – 2032):

- Copper-based DBC Substrates

- Aluminum-based DBC Substrates

- Other Material-based DBC Substrates

-

Geography Outlook (USD Million, 2019 - 2032)

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Chile

- Argentina

- Brazil

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Key Benefits for Stakeholders

- Comprehensive Market Analysis- The study meticulously segments the market based on both economic and non-economic criteria, conducting both qualitative and quantitative analyses. This rigorous approach offers a deep understanding of various market segments and sub-segments.

- Accurate Market Valuation- Precise market values in USD Billion are furnished for each segment and sub-segment, facilitating stakeholders in making precise assessments of market opportunities.

- Identification of Growth Prospects- The report pinpoints regions and market segments poised for rapid expansion, as well as those with substantial market share potential. This assists stakeholders in making well-informed strategic decisions.

- Insightful Regional Analysis- The research explores regional factors influencing the market and scrutinizes product or service utilization in diverse geographical areas, enhancing comprehension of regional dynamics.

- Comprehensive Competitive Insight- The report encompasses critical data, including market share of leading players, recent service/product launches, collaborations, expansions, and acquisitions made by profiled companies in the last five years. This provides a holistic view of the competitive landscape.

- Detailed Company Profiles- In-depth profiles of key market participants encompass company overviews, business insights, product benchmarking, and SWOT analyses. This equips stakeholders with the means to evaluate the strengths and weaknesses of these entities.

- Future Market Outlook- The research furnishes an industry perspective on the present and future based on recent developments, enabling stakeholders to anticipate market trends and forthcoming changes.

- Thorough Market Examination- Porter’s five forces analysis is employed in the study to provide a comprehensive examination of the market from multiple angles, including competitive forces and market dynamics.

- Value Chain Insights- The research leverages the Value Chain concept to elucidate the market, offering insights into how products or services traverse the market ecosystem.

- Market Dynamics and Growth Prospects- The study presents current market dynamics and growth prospects for the foreseeable future, empowering stakeholders with invaluable information for strategic decision-making.

Global DBC Ceramic Substrate Sales Market Report 2018

1 DBC Ceramic Substrate Market Overview

1.1 Product Overview and Scope of DBC Ceramic Substrate

1.2 Classification of DBC Ceramic Substrate by Product Category

1.2.1 Global DBC Ceramic Substrate Market Size (Sales) Comparison by Type (2013-2025)

1.2.2 Global DBC Ceramic Substrate Market Size (Sales) Market Share by Type (Product Category) in 2017

1.2.3 Ceramic Material

1.2.4 Al2O3 (Aluminium Oxide)

1.2.5 AlN (Aluminium Nitride)

1.3 Global DBC Ceramic Substrate Market by Application/End Users

1.3.1 Global DBC Ceramic Substrate Sales (Volume) and Market Share Comparison by Application (2013-2025)

1.3.2 Automotive

1.3.3 Aerospace

1.3.4 Communication

1.3.5 Other

1.4 Global DBC Ceramic Substrate Market by Region

1.4.1 Global DBC Ceramic Substrate Market Size (Value) Comparison by Region (2013-2025)

1.4.2 United States DBC Ceramic Substrate Status and Prospect (2013-2025)

1.4.3 China DBC Ceramic Substrate Status and Prospect (2013-2025)

1.4.4 Europe DBC Ceramic Substrate Status and Prospect (2013-2025)

1.4.5 Japan DBC Ceramic Substrate Status and Prospect (2013-2025)

1.4.6 Southeast Asia DBC Ceramic Substrate Status and Prospect (2013-2025)

1.4.7 India DBC Ceramic Substrate Status and Prospect (2013-2025)

1.5 Global Market Size (Value and Volume) of DBC Ceramic Substrate (2013-2025)

1.5.1 Global DBC Ceramic Substrate Sales and Growth Rate (2013-2025)

1.5.2 Global DBC Ceramic Substrate Revenue and Growth Rate (2013-2025)

2 Global DBC Ceramic Substrate Competition by Players/Suppliers, Type and Application

2.1 Global DBC Ceramic Substrate Market Competition by Players/Suppliers

2.1.1 Global DBC Ceramic Substrate Sales and Market Share of Key Players/Suppliers (2013-2018)

2.1.2 Global DBC Ceramic Substrate Revenue and Share by Players/Suppliers (2013-2018)

2.2 Global DBC Ceramic Substrate (Volume and Value) by Type

2.2.1 Global DBC Ceramic Substrate Sales and Market Share by Type (2013-2018)

2.2.2 Global DBC Ceramic Substrate Revenue and Market Share by Type (2013-2018)

2.3 Global DBC Ceramic Substrate (Volume and Value) by Region

2.3.1 Global DBC Ceramic Substrate Sales and Market Share by Region (2013-2018)

2.3.2 Global DBC Ceramic Substrate Revenue and Market Share by Region (2013-2018)

2.4 Global DBC Ceramic Substrate (Volume) by Application

3 United States DBC Ceramic Substrate (Volume, Value and Sales Price)

3.1 United States DBC Ceramic Substrate Sales and Value (2013-2018)

3.1.1 United States DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

3.1.2 United States DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

3.1.3 United States DBC Ceramic Substrate Sales Price Trend (2013-2018)

3.2 United States DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

3.3 United States DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

3.4 United States DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

4 China DBC Ceramic Substrate (Volume, Value and Sales Price)

4.1 China DBC Ceramic Substrate Sales and Value (2013-2018)

4.1.1 China DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

4.1.2 China DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

4.1.3 China DBC Ceramic Substrate Sales Price Trend (2013-2018)

4.2 China DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

4.3 China DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

4.4 China DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

5 Europe DBC Ceramic Substrate (Volume, Value and Sales Price)

5.1 Europe DBC Ceramic Substrate Sales and Value (2013-2018)

5.1.1 Europe DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

5.1.2 Europe DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

5.1.3 Europe DBC Ceramic Substrate Sales Price Trend (2013-2018)

5.2 Europe DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

5.3 Europe DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

5.4 Europe DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

6 Japan DBC Ceramic Substrate (Volume, Value and Sales Price)

6.1 Japan DBC Ceramic Substrate Sales and Value (2013-2018)

6.1.1 Japan DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

6.1.2 Japan DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

6.1.3 Japan DBC Ceramic Substrate Sales Price Trend (2013-2018)

6.2 Japan DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

6.3 Japan DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

6.4 Japan DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

7 Southeast Asia DBC Ceramic Substrate (Volume, Value and Sales Price)

7.1 Southeast Asia DBC Ceramic Substrate Sales and Value (2013-2018)

7.1.1 Southeast Asia DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

7.1.2 Southeast Asia DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

7.1.3 Southeast Asia DBC Ceramic Substrate Sales Price Trend (2013-2018)

7.2 Southeast Asia DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

7.3 Southeast Asia DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

7.4 Southeast Asia DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

8 India DBC Ceramic Substrate (Volume, Value and Sales Price)

8.1 India DBC Ceramic Substrate Sales and Value (2013-2018)

8.1.1 India DBC Ceramic Substrate Sales and Growth Rate (2013-2018)

8.1.2 India DBC Ceramic Substrate Revenue and Growth Rate (2013-2018)

8.1.3 India DBC Ceramic Substrate Sales Price Trend (2013-2018)

8.2 India DBC Ceramic Substrate Sales Volume and Market Share by Players (2013-2018)

8.3 India DBC Ceramic Substrate Sales Volume and Market Share by Type (2013-2018)

8.4 India DBC Ceramic Substrate Sales Volume and Market Share by Application (2013-2018)

9 Global DBC Ceramic Substrate Players/Suppliers Profiles and Sales Data

9.1 Maruwa

9.1.1 Company Basic Information, Manufacturing Base and Competitors

9.1.2 DBC Ceramic Substrate Product Category, Application and Specification

9.1.2.1 Product A

9.1.2.2 Product B

9.1.3 Maruwa DBC Ceramic Substrate Sales, Revenue, Price and Gross Margin (2013-2018)

9.1.4 Main Business/Business Overview

9.2 Tong Hsing

9.2.1 Company Basic Information, Manufacturing Base and Competitors

9.2.2 DBC Ceramic Substrate Product Category, Application and Specification

9.2.2.1 Product A

9.2.2.2 Product B

9.2.3 Tong Hsing DBC Ceramic Substrate Sales, Revenue, Price and Gross Margin (2013-2018)

9.2.4 Main Business/Business Overview

9.3 Rogers Corporation

9.3.1 Company Basic Information, Manufacturing Base and Competitors

9.3.2 DBC Ceramic Substrate Product Category, Application and Specification

9.3.2.1 Product A

9.3.2.2 Product B

9.3.3 Rogers Corporation DBC Ceramic Substrate Sales, Revenue, Price and Gross Margin (2013-2018)

9.3.4 Main Business/Business Overview

9.4 Ferrotec

9.4.1 Company Basic Information, Manufacturing Base and Competitors

9.4.2 DBC Ceramic Substrate Product Category, Application and Specification

9.4.2.1 Product A

9.4.2.2 Product B

9.4.3 Ferrotec DBC Ceramic Substrate Sales, Revenue, Price and Gross Margin (2013-2018)

9.4.4 Main Business/Business Overview

9.5 Stellar Ceramics

9.5.1 Company Basic Information, Manufacturing Base and Competitors

9.5.2 DBC Ceramic Substrate Product Category, Application and Specification

9.5.2.1 Product A

9.5.2.2 Product B

9.5.3 Stellar Ceramics DBC Ceramic Substrate Sales, Revenue, Price and Gross Margin (2013-2018)

9.5.4 Main Business/Business Overview

...

10 DBC Ceramic Substrate Maufacturing Cost Analysis

10.1 DBC Ceramic Substrate Key Raw Materials Analysis

10.1.1 Key Raw Materials

10.1.2 Price Trend of Key Raw Materials

10.1.3 Key Suppliers of Raw Materials

10.1.4 Market Concentration Rate of Raw Materials

10.2 Proportion of Manufacturing Cost Structure

10.2.1 Raw Materials

10.2.2 Labor Cost

10.2.3 Manufacturing Process Analysis of DBC Ceramic Substrate

10.3 Manufacturing Process Analysis of DBC Ceramic Substrate

11 Industrial Chain, Sourcing Strategy and Downstream Buyers

11.1 DBC Ceramic Substrate Industrial Chain Analysis

11.2 Upstream Raw Materials Sourcing

11.3 Raw Materials Sources of DBC Ceramic Substrate Major Manufacturers in 2017

11.4 Downstream Buyers

12 Marketing Strategy Analysis, Distributors/Traders

12.1 Marketing Channel

12.1.1 Direct Marketing

12.1.2 Indirect Marketing

12.1.3 Marketing Channel Development Trend

12.2 Market Positioning

12.2.1 Pricing Strategy

12.2.2 Brand Strategy

12.2.3 Target Client

12.3 Distributors/Traders List

13 Market Effect Factors Analysis

13.1 Technology Progress/Risk

13.1.1 Substitutes Threat

13.1.2 Technology Progress in Related Industry

13.2 Consumer Needs/Customer Preference Change

13.3 Economic/Political Environmental Change

14 Global DBC Ceramic Substrate Market Forecast (2018-2025)

14.1 Global DBC Ceramic Substrate Sales Volume, Revenue and Price Forecast (2018-2025)

14.1.1 Global DBC Ceramic Substrate Sales Volume and Growth Rate Forecast (2018-2025)

14.1.2 Global DBC Ceramic Substrate Revenue and Growth Rate Forecast (2018-2025)

14.1.3 Global DBC Ceramic Substrate Price and Trend Forecast (2018-2025)

14.2 Global DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast by Region (2018-2025)

14.2.1 Global DBC Ceramic Substrate Sales Volume and Growth Rate Forecast by Regions (2018-2025)

14.2.2 Global DBC Ceramic Substrate Revenue and Growth Rate Forecast by Regions (2018-2025)

14.2.3 United States DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.2.4 China DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.2.5 Europe DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.2.6 Japan DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.2.7 Southeast Asia DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.2.8 India DBC Ceramic Substrate Sales Volume, Revenue and Growth Rate Forecast (2018-2025)

14.3 Global DBC Ceramic Substrate Sales Volume, Revenue and Price Forecast by Type (2018-2025)

14.3.1 Global DBC Ceramic Substrate Sales Forecast by Type (2018-2025)

14.3.2 Global DBC Ceramic Substrate Revenue Forecast by Type (2018-2025)

14.3.3 Global DBC Ceramic Substrate Price Forecast by Type (2018-2025)

14.4 Global DBC Ceramic Substrate Sales Volume Forecast by Application (2018-2025)

15 Research Findings and Conclusion

16 Appendix

16.1 Methodology/Research Approach

16.1.1 Research Programs/Design

16.1.2 Market Size Estimation

16.1.3 Market Breakdown and Data Triangulation

16.2 Data Source

16.2.1 Secondary Sources

16.2.2 Primary Sources

16.3 Disclaimer

List of Tables and Figures

Figure Product Picture of DBC Ceramic Substrate

Figure Global DBC Ceramic Substrate Sales Volume Comparison (K Units) by Type (2013-2025)

Figure Global DBC Ceramic Substrate Sales Volume Market Share by Type (Product Category) in 2017

Figure Ceramic Material Product Picture

Figure Al2O3 (Aluminium Oxide) Product Picture

Figure AlN (Aluminium Nitride) Product Picture

Figure Global DBC Ceramic Substrate Sales Comparison (K Units) by Application (2013-2025)

Figure Global Sales Market Share of DBC Ceramic Substrate by Application in 2017

Figure Automotive Examples

Table Key Downstream Customer in Automotive

Figure Aerospace Examples

Table Key Downstream Customer in Aerospace

Figure Communication Examples

Table Key Downstream Customer in Communication

Figure Other Examples

Table Key Downstream Customer in Other

Figure Global DBC Ceramic Substrate Market Size (Million USD) by Regions (2013-2025)

Figure United States DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure China DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure Europe DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure Japan DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure Southeast Asia DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure India DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure Global DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate (2013-2025)

Figure Global DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2025)

Figure Global Market Major Players DBC Ceramic Substrate Sales Volume (K Units) (2013-2018)

Table Global DBC Ceramic Substrate Sales (K Units) of Key Players/Suppliers (2013-2018)

Table Global DBC Ceramic Substrate Sales Share by Players/Suppliers (2013-2018)

Figure 2017 DBC Ceramic Substrate Sales Share by Players/Suppliers

Figure 2017 DBC Ceramic Substrate Sales Share by Players/Suppliers

Figure Global DBC Ceramic Substrate Revenue (Million USD) by Players/Suppliers (2013-2018)

Table Global DBC Ceramic Substrate Revenue (Million USD) by Players/Suppliers (2013-2018)

Table Global DBC Ceramic Substrate Revenue Share by Players/Suppliers (2013-2018)

Table 2017 Global DBC Ceramic Substrate Revenue Share by Players

Table 2017 Global DBC Ceramic Substrate Revenue Share by Players

Table Global DBC Ceramic Substrate Sales (K Units) and Market Share by Type (2013-2018)

Table Global DBC Ceramic Substrate Sales Share (K Units) by Type (2013-2018)

Figure Sales Market Share of DBC Ceramic Substrate by Type (2013-2018)

Figure Global DBC Ceramic Substrate Sales Growth Rate by Type (2013-2018)

Table Global DBC Ceramic Substrate Revenue (Million USD) and Market Share by Type (2013-2018)

Table Global DBC Ceramic Substrate Revenue Share by Type (2013-2018)

Figure Revenue Market Share of DBC Ceramic Substrate by Type (2013-2018)

Figure Global DBC Ceramic Substrate Revenue Growth Rate by Type (2013-2018)

Table Global DBC Ceramic Substrate Sales Volume (K Units) and Market Share by Region (2013-2018)

Table Global DBC Ceramic Substrate Sales Share by Region (2013-2018)

Figure Sales Market Share of DBC Ceramic Substrate by Region (2013-2018)

Figure Global DBC Ceramic Substrate Sales Growth Rate by Region in 2017

Table Global DBC Ceramic Substrate Revenue (Million USD) and Market Share by Region (2013-2018)

Table Global DBC Ceramic Substrate Revenue Share (%) by Region (2013-2018)

Figure Revenue Market Share of DBC Ceramic Substrate by Region (2013-2018)

Figure Global DBC Ceramic Substrate Revenue Growth Rate by Region in 2017

Table Global DBC Ceramic Substrate Revenue (Million USD) and Market Share by Region (2013-2018)

Table Global DBC Ceramic Substrate Revenue Share (%) by Region (2013-2018)

Figure Revenue Market Share of DBC Ceramic Substrate by Region (2013-2018)

Figure Global DBC Ceramic Substrate Revenue Market Share by Region in 2017

Table Global DBC Ceramic Substrate Sales Volume (K Units) and Market Share by Application (2013-2018)

Table Global DBC Ceramic Substrate Sales Share (%) by Application (2013-2018)

Figure Sales Market Share of DBC Ceramic Substrate by Application (2013-2018)

Figure Global DBC Ceramic Substrate Sales Market Share by Application (2013-2018)

Figure United States DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure United States DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure United States DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table United States DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table United States DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure United States DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table United States DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table United States DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure United States DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table United States DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table United States DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure United States DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Figure China DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure China DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure China DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table China DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table China DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure China DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table China DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table China DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure China DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table China DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table China DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure China DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Figure Europe DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure Europe DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure Europe DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table Europe DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table Europe DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure Europe DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table Europe DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table Europe DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure Europe DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table Europe DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table Europe DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure Europe DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Figure Japan DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure Japan DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure Japan DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table Japan DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table Japan DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure Japan DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table Japan DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table Japan DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure Japan DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table Japan DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table Japan DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure Japan DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Figure Southeast Asia DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure Southeast Asia DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure Southeast Asia DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table Southeast Asia DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table Southeast Asia DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table Southeast Asia DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure Southeast Asia DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Figure India DBC Ceramic Substrate Sales (K Units) and Growth Rate (2013-2018)

Figure India DBC Ceramic Substrate Revenue (Million USD) and Growth Rate (2013-2018)

Figure India DBC Ceramic Substrate Sales Price (USD/Unit) Trend (2013-2018)

Table India DBC Ceramic Substrate Sales Volume (K Units) by Players (2013-2018)

Table India DBC Ceramic Substrate Sales Volume Market Share by Players (2013-2018)

Figure India DBC Ceramic Substrate Sales Volume Market Share by Players in 2017

Table India DBC Ceramic Substrate Sales Volume (K Units) by Type (2013-2018)

Table India DBC Ceramic Substrate Sales Volume Market Share by Type (2013-2018)

Figure India DBC Ceramic Substrate Sales Volume Market Share by Type in 2017

Table India DBC Ceramic Substrate Sales Volume (K Units) by Application (2013-2018)

Table India DBC Ceramic Substrate Sales Volume Market Share by Application (2013-2018)

Figure India DBC Ceramic Substrate Sales Volume Market Share by Application in 2017

Table Maruwa Basic Information List

Table Maruwa DBC Ceramic Substrate Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (2013-2018)

Figure Maruwa DBC Ceramic Substrate Sales Growth Rate (2013-2018)

Figure Maruwa DBC Ceramic Substrate Sales Global Market Share (2013-2018)

Figure Maruwa DBC Ceramic Substrate Revenue Global Market Share (2013-2018)

Table Tong Hsing Basic Information List

Table Tong Hsing DBC Ceramic Substrate Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (2013-2018)

Figure Tong Hsing DBC Ceramic Substrate Sales Growth Rate (2013-2018)

Figure Tong Hsing DBC Ceramic Substrate Sales Global Market Share (2013-2018)

Figure Tong Hsing DBC Ceramic Substrate Revenue Global Market Share (2013-2018)

Table Rogers Corporation Basic Information List

Table Rogers Corporation DBC Ceramic Substrate Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (2013-2018)

Figure Rogers Corporation DBC Ceramic Substrate Sales Growth Rate (2013-2018)

Figure Rogers Corporation DBC Ceramic Substrate Sales Global Market Share (2013-2018

Figure Rogers Corporation DBC Ceramic Substrate Revenue Global Market Share (2013-2018)

Table Ferrotec Basic Information List

Table Ferrotec DBC Ceramic Substrate Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (2013-2018)

Figure Ferrotec DBC Ceramic Substrate Sales Growth Rate (2013-2018)

Figure Ferrotec DBC Ceramic Substrate Sales Global Market Share (2013-2018)

Figure Ferrotec DBC Ceramic Substrate Revenue Global Market Share (2013-2018)

Table Stellar Ceramics Basic Information List

Table Stellar Ceramics DBC Ceramic Substrate Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (2013-2018)

Figure Stellar Ceramics DBC Ceramic Substrate Sales Growth Rate (2013-2018)

Figure Stellar Ceramics DBC Ceramic Substrate Sales Global Market Share (2013-2018)

Figure Stellar Ceramics DBC Ceramic Substrate Revenue Global Market Share (2013-2018)

Table Production Base and Market Concentration Rate of Raw Material

Figure Price Trend of Key Raw Materials

Table Key Suppliers of Raw Materials

Figure Manufacturing Cost Structure of DBC Ceramic Substrate

Figure Manufacturing Process Analysis of DBC Ceramic Substrate

Figure DBC Ceramic Substrate Industrial Chain Analysis

Table Raw Materials Sources of DBC Ceramic Substrate Major Players in 2017

Table Major Buyers of DBC Ceramic Substrate

Table Distributors/Traders List

Figure Global DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure Global DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure Global DBC Ceramic Substrate Price (USD/Unit) and Trend Forecast (2018-2025)

Table Global DBC Ceramic Substrate Sales Volume (K Units) Forecast by Regions (2018-2025)

Figure Global DBC Ceramic Substrate Sales Volume Market Share Forecast by Regions (2018-2025)

Figure Global DBC Ceramic Substrate Sales Volume Market Share Forecast by Regions in 2025

Table Global DBC Ceramic Substrate Revenue (Million USD) Forecast by Regions (2018-2025)

Figure Global DBC Ceramic Substrate Revenue Market Share Forecast by Regions (2018-2025)

Figure Global DBC Ceramic Substrate Revenue Market Share Forecast by Regions in 2025

Figure United States DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure United States DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure China DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure China DBC Ceramic Substrate Revenue and Growth Rate Forecast (2018-2025)

Figure Europe DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure Europe DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure Japan DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure Japan DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure Southeast Asia DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure Southeast Asia DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure India DBC Ceramic Substrate Sales Volume (K Units) and Growth Rate Forecast (2018-2025)

Figure India DBC Ceramic Substrate Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table Global DBC Ceramic Substrate Sales (K Units) Forecast by Type (2018-2025)

Figure Global DBC Ceramic Substrate Sales Volume Market Share Forecast by Type (2018-2025)

Table Global DBC Ceramic Substrate Revenue (Million USD) Forecast by Type (2018-2025)

Figure Global DBC Ceramic Substrate Revenue Market Share Forecast by Type (2018-2025)

Table Global DBC Ceramic Substrate Price (USD/Unit) Forecast by Type (2018-2025)

Table Global DBC Ceramic Substrate Sales (K Units) Forecast by Application (2018-2025)

Figure Global DBC Ceramic Substrate Sales Market Share Forecast by Application (2018-2025)

Table Research Programs/Design for This Report

Figure Bottom-up and Top-down Approaches for This Report

Figure Data Triangulation

Table Key Data Information from Secondary Sources

Table Key Data Information from Primary Sources

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"