Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 7.97 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The E-Chuck for Wafer Market size is estimated to grow at a CAGR of 8.45% between 2022 and 2032. The market size is forecast to increase by USD 1,567.89 million. The growth of the market depends on several factors, including the increasing demand for advanced semiconductor manufacturing technologies, rising adoption of wafer-level packaging, and the growing focus on improving wafer yield and quality. E-Chuck, also known as an electrostatic chuck, is a critical component used in semiconductor manufacturing processes to hold and secure wafers during various fabrication steps.

E-Chuck for Wafer Market Overview:

Drivers:

One of the key factors driving the E-Chuck for wafer market growth is the increasing demand for advanced semiconductor manufacturing technologies. With the rapid advancements in the semiconductor industry, there is a growing need for more precise and efficient wafer handling solutions. E-Chucks offer superior wafer clamping capabilities, excellent temperature control, and enhanced process stability, thereby improving overall manufacturing efficiency and yield. The increasing complexity of semiconductor devices, such as 3D integrated circuits and advanced packaging, further drives the demand for E-Chucks that can handle thinner and larger wafers with higher accuracy.

Moreover, the adoption of wafer-level packaging is also driving the market growth. Wafer-level packaging (WLP) is a technology that enables the integration of multiple semiconductor components on a single wafer, eliminating the need for individual packaging. E-Chucks play a crucial role in the WLP process by securely holding the wafer during the packaging steps. The growing demand for compact and lightweight electronic devices, such as smartphones and wearables, is fueling the adoption of WLP, thereby driving the demand for E-Chucks.

Trends:

A key trend shaping the E-Chuck for wafer market is the integration of advanced materials and technologies. Manufacturers are incorporating innovative materials, such as ceramics and composites, in E-Chuck designs to improve thermal conductivity, reduce wafer warpage, and enhance overall performance. Additionally, the integration of advanced sensing and control technologies, such as temperature sensors and feedback systems, allows for real-time monitoring and adjustment of the E-Chuck parameters, ensuring optimal wafer handling and process control.

Furthermore, there is a growing focus on improving wafer yield and quality, which is driving the demand for advanced E-Chuck solutions. Manufacturers are developing E-Chucks with enhanced clamping mechanisms, uniform temperature distribution, and reduced particle generation to minimize wafer damage and contamination. These advancements in E-Chuck technology help semiconductor manufacturers achieve higher yields, lower defect rates, and improved overall product quality.

Restraints:

One of the key challenges hindering the E-Chuck for wafer market growth is the high cost of advanced E-Chuck solutions. The development and manufacturing of E-Chucks with advanced materials, technologies, and precision engineering involve significant investments. The high cost of these E-Chucks may limit their adoption, especially among small and medium-sized semiconductor manufacturers with budget constraints. Additionally, the complexity of integrating E-Chucks into existing semiconductor manufacturing equipment and processes can pose challenges, further impacting market growth.

E-Chuck for Wafer Market Segmentation By Application:

The front-end wafer processing segment is estimated to witness significant growth during the forecast period. E-Chucks play a critical role in front-end wafer processing steps, such as lithography, etching, and deposition. They provide precise wafer clamping, temperature control, and electrostatic discharge protection, ensuring accurate alignment and uniform processing across the wafer surface. The increasing demand for advanced semiconductor devices with smaller feature sizes and higher integration levels drives the need for E-Chucks that can handle larger wafers and enable finer process control.

The back-end wafer processing segment is also expected to contribute to the market growth. E-Chucks are used in back-end processes, including wafer dicing, die bonding, and packaging. They provide secure wafer handling during these critical steps, ensuring proper alignment and protection of the delicate semiconductor components. The growing adoption of wafer-level packaging and advanced packaging technologies drives the demand for E-Chucks in back-end wafer processing.

E-Chuck for Wafer Market Segmentation By Type:

The electrostatic-based E-Chuck segment is expected to dominate the market during the forecast period. Electrostatic E-Chucks use electrostatic forces to hold and secure wafers, offering precise clamping and excellent temperature control. They are widely used in semiconductor manufacturing processes due to their high accuracy, low particle generation, and compatibility with various wafer sizes and materials. The increasing demand for advanced wafer handling solutions that can accommodate thinner wafers and enable higher process control drives the growth of this segment.

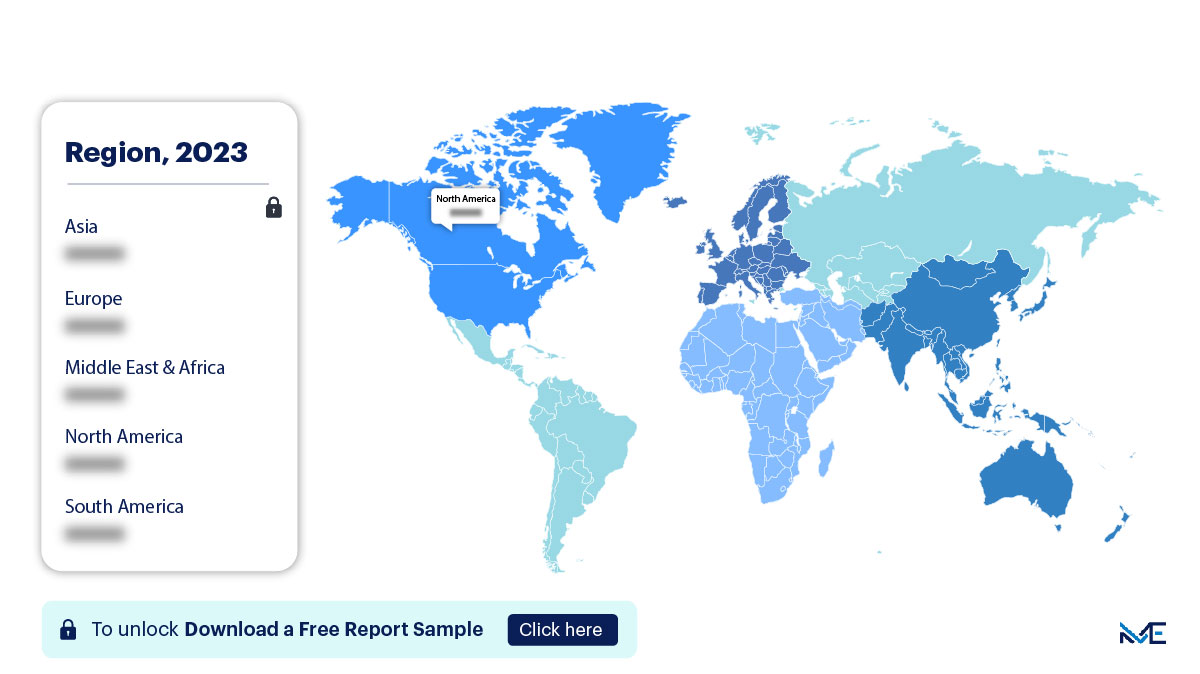

Regional Overview:

Download the report summary now!

Request pdf Sample

North America is estimated to contribute significantly to the growth of the global E-Chuck for wafer market during the forecast period. The region has a strong presence of leading semiconductor manufacturers, research institutions, and technological advancements, driving the demand for advanced wafer handling solutions. The increasing investments in semiconductor fabrication facilities and the growing focus on developing advanced semiconductor devices further support market growth in North America.

Asia Pacific is also expected to witness substantial growth in the E-Chuck for wafer market. The region is a major hub for semiconductor manufacturing, with countries like China, South Korea, and Taiwan leading in semiconductor production. The increasing demand for consumer electronics, automotive electronics, and industrial automation drives the need for advanced wafer handling solutions, including E-Chucks.

E-Chuck for Wafer Market Customer Landscape:

The E-Chuck for wafer market industry report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their growth strategies.

Who are the Major E-Chuck for Wafer Market Companies?

Companies are implementing various strategies, such as product launches, partnerships, mergers and acquisitions, and geographical expansion, to enhance their presence in the market.

Applied Materials Inc: The company offers a range of E-Chuck solutions for wafer processing, including electrostatic-based E-Chucks.

Lam Research Corporation: The company provides advanced E-Chucks for wafer handling in semiconductor manufacturing processes.

Tokyo Electron Limited: The company offers E-Chucks with advanced temperature control and wafer clamping capabilities.

Some of the major companies operating in the E-Chuck for wafer market include:

- Applied Materials Inc.

- Disco Corporation

- Hitachi High-Tech Corporation

- KLA Corporation

- Lam Research Corporation

- Nikon Corporation

- Semiconductor Manufacturing International Corporation

- Tokyo Electron Limited

- Toshiba Corporation

- ULVAC Technologies Inc.

The research report also includes detailed analyses of the competitive landscape of the market and information about key market players. Data is qualitatively analyzed to categorize companies based on their market presence and strength.

Segment Overview:

The E-Chuck for wafer market report forecasts market growth by revenue at global, regional, and country levels and provides an analysis of the latest trends and growth opportunities from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032)

o Front-end Wafer Processing

o Back-end Wafer Processing

- Type Outlook (USD Million, 2019 - 2032)

o Electrostatic-based

o Other Technologies

- Geography Outlook (USD Million, 2019 - 2032)

o North America

- The U.S.

- Canada

o Europe

- K.

- Germany

- France

- Rest of Europe

o Asia Pacific

- China

- Japan

- South Korea

o South America

- Brazil

- Argentina

- Rest of South America

o Middle East & Africa

- Saudi Arabia

- United Arab Emirates

- Rest of Middle East & Africa

Key Benefits for Stakeholders

- Comprehensive Market Analysis- The study meticulously segments the market based on both economic and non-economic criteria, conducting both qualitative and quantitative analyses. This rigorous approach offers a deep understanding of various market segments and sub-segments.

- Accurate Market Valuation- Precise market values in USD Billion are furnished for each segment and sub-segment, facilitating stakeholders in making precise assessments of market opportunities.

- Identification of Growth Prospects- The report pinpoints regions and market segments poised for rapid expansion, as well as those with substantial market share potential. This assists stakeholders in making well-informed strategic decisions.

- Insightful Regional Analysis- The research explores regional factors influencing the market and scrutinizes product or service utilization in diverse geographical areas, enhancing comprehension of regional dynamics.

- Comprehensive Competitive Insight- The report encompasses critical data, including market share of leading players, recent service/product launches, collaborations, expansions, and acquisitions made by profiled companies in the last five years. This provides a holistic view of the competitive landscape.

- Detailed Company Profiles- In-depth profiles of key market participants encompass company overviews, business insights, product benchmarking, and SWOT analyses. This equips stakeholders with the means to evaluate the strengths and weaknesses of these entities.

- Future Market Outlook- The research furnishes an industry perspective on the present and future based on recent developments, enabling stakeholders to anticipate market trends and forthcoming changes.

- Thorough Market Examination- Porter’s five forces analysis is employed in the study to provide a comprehensive examination of the market from multiple angles, including competitive forces and market dynamics.

- Value Chain Insights- The research leverages the Value Chain concept to elucidate the market, offering insights into how products or services traverse the market ecosystem.

- Market Dynamics and Growth Prospects- The study presents current market dynamics and growth prospects for the foreseeable future, empowering stakeholders with invaluable information for strategic decision-making.

1 E-Chuck for Wafer Market Overview

1.1 E-Chuck for Wafer Product Overview

1.2 E-Chuck for Wafer Market Segment by Type

1.2.1 Coulomb Type E-Chuck for Wafer

1.2.2 Johnsen-Rahbek (JR) Type E-Chuck for Wafer

1.3 Global E-Chuck for Wafer Market Size by Type

1.3.1 Global E-Chuck for Wafer Sales and Growth by Type

1.3.2 Global E-Chuck for Wafer Sales and Market Share by Type (2014-2019)

1.3.3 Global E-Chuck for Wafer Revenue and Market Share by Type (2014-2019)

1.3.4 Global E-Chuck for Wafer Price by Type (2014-2019)

2 Global E-Chuck for Wafer Market Competition by Company

2.1 Global E-Chuck for Wafer Sales and Market Share by Company (2014-2019)

2.2 Global E-Chuck for Wafer Revenue and Share by Company (2014-2019)

2.3 Global E-Chuck for Wafer Price by Company (2014-2019)

2.4 Global Top Players E-Chuck for Wafer Manufacturing Base Distribution, Sales Area, Product Types

2.5 E-Chuck for Wafer Market Competitive Situation and Trends

2.5.1 E-Chuck for Wafer Market Concentration Rate

2.5.2 Global E-Chuck for Wafer Market Share of Top 5 and Top 10 Players

2.5.3 Mergers & Acquisitions, Expansion

3 E-Chuck for Wafer Company Profiles and Sales Data

3.1 SHINKO

3.1.1 Company Basic Information, Manufacturing Base and Competitors

3.1.2 E-Chuck for Wafer Product Category, Application and Specification

3.1.3 SHINKO E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.1.4 Main Business Overview

3.2 TOTO

3.2.1 Company Basic Information, Manufacturing Base and Competitors

3.2.2 E-Chuck for Wafer Product Category, Application and Specification

3.2.3 TOTO E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.2.4 Main Business Overview

3.3 Creative Technology Corporation

3.3.1 Company Basic Information, Manufacturing Base and Competitors

3.3.2 E-Chuck for Wafer Product Category, Application and Specification

3.3.3 Creative Technology Corporation E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.3.4 Main Business Overview

3.4 Kyocera

3.4.1 Company Basic Information, Manufacturing Base and Competitors

3.4.2 E-Chuck for Wafer Product Category, Application and Specification

3.4.3 Kyocera E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.4.4 Main Business Overview

3.5 FM Industries

3.5.1 Company Basic Information, Manufacturing Base and Competitors

3.5.2 E-Chuck for Wafer Product Category, Application and Specification

3.5.3 FM Industries E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.5.4 Main Business Overview

3.6 NTK CERATEC

3.6.1 Company Basic Information, Manufacturing Base and Competitors

3.6.2 E-Chuck for Wafer Product Category, Application and Specification

3.6.3 NTK CERATEC E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.6.4 Main Business Overview

3.7 Tsukuba Seiko

3.7.1 Company Basic Information, Manufacturing Base and Competitors

3.7.2 E-Chuck for Wafer Product Category, Application and Specification

3.7.3 Tsukuba Seiko E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.7.4 Main Business Overview

3.8 Applied Materials

3.8.1 Company Basic Information, Manufacturing Base and Competitors

3.8.2 E-Chuck for Wafer Product Category, Application and Specification

3.8.3 Applied Materials E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.8.4 Main Business Overview

3.9 II-VI M Cubed

3.9.1 Company Basic Information, Manufacturing Base and Competitors

3.9.2 E-Chuck for Wafer Product Category, Application and Specification

3.9.3 II-VI M Cubed E-Chuck for Wafer Sales, Revenue, Price and Gross Margin(2014-2019)

3.9.4 Main Business Overview

4 E-Chuck for Wafer Market Status and Outlook by Regions

4.1 Global Market Status and Outlook by Regions

4.1.1 Global E-Chuck for Wafer Market Size and CAGR by Regions

4.1.2 North America

4.1.3 Asia-Pacific

4.1.4 Europe

4.1.5 South America

4.1.6 Middle East and Africa

4.2 Global E-Chuck for Wafer Sales and Revenue by Regions

4.2.1 Global E-Chuck for Wafer Sales and Market Share by Regions (2014-2019)

4.2.2 Global E-Chuck for Wafer Revenue and Market Share by Regions (2014-2019)

4.2.3 Global E-Chuck for Wafer Sales, Revenue, Price and Gross Margin (2014-2019)

4.3 North America E-Chuck for Wafer Sales, Revenue, Price and Gross Margin

4.3.1 United States

4.3.2 Canada

4.3.3 Mexico

4.4 Europe E-Chuck for Wafer Sales, Revenue, Price and Gross Margin

4.4.1 Germany

4.4.2 UK

4.4.3 France

4.4.4 Italy

4.4.5 Russia

4.4.6 Turkey

4.5 Asia-Pacific E-Chuck for Wafer Sales, Revenue, Price and Gross Margin

4.5.1 China

4.5.2 Japan

4.5.3 Korea

4.5.4 Southeast Asia

4.5.4.1 Indonesia

4.5.4.2 Thailand

4.5.4.3 Malaysia

4.5.4.4 Philippines

4.5.4.5 Vietnam

4.5.5 India

4.5.6 Australia

4.6 South America E-Chuck for Wafer Sales, Revenue, Price and Gross Margin

4.6.1 Brazil

4.7 Middle East and Africa E-Chuck for Wafer Sales, Revenue, Price and Gross Margin

4.7.1 Egypt

4.7.2 GCC Countries

5 E-Chuck for Wafer Application/End Users

5.1 E-Chuck for Wafer Segment by Application

5.1.1 300 mm Wafer

5.1.2 200 mm Wafer

5.1.3 Others

5.2 Global E-Chuck for Wafer Product Segment by Application

5.2.1 Global E-Chuck for Wafer Sales by Application

5.2.2 Global E-Chuck for Wafer Sales and Market Share by Application (2014-2019)

6 Global E-Chuck for Wafer Market Forecast

6.1 Global E-Chuck for Wafer Sales, Revenue Forecast (2019-2025)

6.1.1 Global E-Chuck for Wafer Sales and Growth Rate Forecast (2019-2025)

6.1.1 Global E-Chuck for Wafer Revenue and Growth Rate Forecast (2019-2025)

6.2 Global E-Chuck for Wafer Forecast by Regions

6.2.1 North America E-Chuck for Wafer Sales and Revenue Forecast (2019-2025)

6.2.2 Europe E-Chuck for Wafer Sales and Revenue Forecast (2019-2025)

6.2.3 Asia-Pacific E-Chuck for Wafer Sales and Revenue Forecast (2019-2025)

6.2.3.1 China

6.2.3.2 Japan

6.2.3.3 Korea

6.2.3.4 Southeast Asia

6.2.3.5 India

6.2.3.6 Australia

6.2.4 South America E-Chuck for Wafer Sales and Revenue Forecast (2019-2025)

6.2.5 Middle East and Africa E-Chuck for Wafer Sales and Revenue Forecast (2019-2025)

6.2.5.1 Egypt

6.2.5.2 GCC Countries

6.3 E-Chuck for Wafer Forecast by Type

6.3.1 Global E-Chuck for Wafer Sales and Revenue Forecast by Type (2019-2025)

6.3.2 Coulomb Type E-Chuck for Wafer Gowth Forecast

6.3.3 Johnsen-Rahbek (JR) Type E-Chuck for Wafer Gowth Forecast

6.4 E-Chuck for Wafer Forecast by Application

6.4.1 Global E-Chuck for Wafer Sales Forecast by Application (2019-2025)

6.4.2 Global E-Chuck for Wafer Forecast in 300 mm Wafer

6.4.3 Global E-Chuck for Wafer Forecast in 200 mm Wafer

7 E-Chuck for Wafer Upstream Raw Materials

7.1 E-Chuck for Wafer Key Raw Materials

7.1.1 Key Raw Materials

7.1.2 Key Raw Materials Price

7.1.3 Raw Materials Key Suppliers

7.2 Manufacturing Cost Structure

7.2.1 Raw Materials

7.2.2 Labor Cost

7.2.3 Manufacturing Expenses

7.3 E-Chuck for Wafer Industrial Chain Analysis

8 Marketing Strategy Analysis, Distributors

8.1 Marketing Channel

8.1.1 Direct Marketing

8.1.2 Indirect Marketing

8.1.3 Marketing Channel Development Trend

8.2 Distributors

8.3 Downstream Customers

9 Research Findings and Conclusion

Appendix

Methodology/Research Approach

Research Programs/Design

Market Size Estimation

Market Breakdown and Data Triangulation

Data Source

Secondary Sources

Primary Sources

Disclaimer

List of Tables and Figures

Figure E-Chuck for Wafer Product Picture

Figure Global E-Chuck for Wafer Revenue (Million USD) Status and Outlook (2014-2025)

Figure Global E-Chuck for Wafer Sales (K Units) Status and Outlook (2014-2025)

Figure Product Picture of Coulomb Type E-Chuck for Wafer

Table Major Players of Coulomb Type E-Chuck for Wafer

Figure Global Coulomb Type E-Chuck for Wafer Sales (K Units) and Growth Rate (%)(2014-2018)

Figure Product Picture of Johnsen-Rahbek (JR) Type E-Chuck for Wafer

Table Major Players of Johnsen-Rahbek (JR) Type E-Chuck for Wafer

Figure Global Johnsen-Rahbek (JR) Type E-Chuck for Wafer Sales (K Units) and Growth Rate (%)(2014-2019)

Table Global E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Comparison by Type

Table Global E-Chuck for Wafer Sales (K Units) by Type (2014-2019)

Table Global E-Chuck for Wafer Sales Share (%) by Type (2014-2019)

Figure Global E-Chuck for Wafer Sales Market Share (%) by Type (2014-2019)

Figure Global E-Chuck for Wafer Sales Market Share (%) by Type in 2018

Table Global E-Chuck for Wafer Revenue (Million USD) by Type (2014-2019)

Table Global E-Chuck for Wafer Revenue Share (%) by Type (2014-2019)

Figure Global E-Chuck for Wafer Revenue Share (%) by Type (2014-2019)

Figure 2018 Global E-Chuck for Wafer Revenue Market Share (%) by Type

Table Global E-Chuck for Wafer Price (USD/Unit) by Type (2014-2019)

Table Global E-Chuck for Wafer Sales (K Units) by Company (2014-2019)

Table Global E-Chuck for Wafer Sales Share (%) by Company (2014-2019)

Figure Global E-Chuck for Wafer Sales Share (%) by Company in 2018

Table Global E-Chuck for Wafer Revenue (Million USD) by Company (2014-2019)

Table Global E-Chuck for Wafer Revenue Share (%) by Company (2014-2019)

Figure Global E-Chuck for Wafer Revenue Share (%) by Company in 2018

Table Global Market E-Chuck for Wafer Average Price (USD/Unit) by Company (2014-2019)

Table Global E-Chuck for Wafer Top Players Manufacturing Base Distribution and Sales Area

Table Global E-Chuck for Wafer Top Players Product Category

Figure Global E-Chuck for Wafer Market Share (%) of Top 5 Players

Figure Global E-Chuck for Wafer Market Share (%) of Top 10 Players

Table SHINKO Basic Information List

Table SHINKO E-Chuck for Wafer Product Category, Application and Specification

Table SHINKO E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure SHINKO E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure SHINKO E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table TOTO Basic Information List

Figure TOTO E-Chuck for Wafer Product Category, Application and Specification

Table TOTO E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure TOTO E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure TOTO E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table Creative Technology Corporation Basic Information List

Figure Creative Technology Corporation E-Chuck for Wafer Product Category, Application and Specification

Table Creative Technology Corporation E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Creative Technology Corporation E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure Creative Technology Corporation E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table Kyocera Basic Information List

Figure Kyocera E-Chuck for Wafer Product Category, Application and Specification

Table Kyocera E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Kyocera E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure Kyocera E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table FM Industries Basic Information List

Figure FM Industries E-Chuck for Wafer Product Category, Application and Specification

Table FM Industries E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure FM Industries E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure FM Industries E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table NTK CERATEC Basic Information List

Figure NTK CERATEC E-Chuck for Wafer Product Category, Application and Specification

Table NTK CERATEC E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure NTK CERATEC E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure NTK CERATEC E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table Tsukuba Seiko Basic Information List

Figure Tsukuba Seiko E-Chuck for Wafer Product Category, Application and Specification

Table Tsukuba Seiko E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Tsukuba Seiko E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure Tsukuba Seiko E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table Applied Materials Basic Information List

Figure Applied Materials E-Chuck for Wafer Product Category, Application and Specification

Table Applied Materials E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Applied Materials E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure Applied Materials E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table II-VI M Cubed Basic Information List

Figure II-VI M Cubed E-Chuck for Wafer Product Category, Application and Specification

Table II-VI M Cubed E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure II-VI M Cubed E-Chuck for Wafer Sales Growth Rate (2014-2019)

Figure II-VI M Cubed E-Chuck for Wafer Sales Global Market Share (%)(2014-2019)

Table Global E-Chuck for Wafer Market Size Comparison by Regions (2014-2025)

Figure North America E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%)(2014-2025)

Figure Asia-Pacific E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%)(2014-2025)

Figure Europe E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%)(2014-2025)

Figure South America E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%)(2014-2025)

Figure Middle East and Africa E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%)(2014-2025)

Table Global E-Chuck for Wafer Sales (K Units) by Regions (2014-2019)

Table Global E-Chuck for Wafer Sales Market Share (%) by Regions (2014-2019)

Figure Global E-Chuck for Wafer Sales Market Share (%) by Regions (2014-2019)

Figure 2018 Global E-Chuck for Wafer Sales Market Share (%) by Regions

Table Global E-Chuck for Wafer Revenue (Million USD) by Regions (2014-2019)

Table Global E-Chuck for Wafer Revenue Market Share (%) by Regions (2014-2019)

Figure Global E-Chuck for Wafer Revenue Market Share (%) by Regions (2014-2019)

Figure 2018 Global E-Chuck for Wafer Revenue Market Share (%) by Regions

Table Global E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure North America E-Chuck for Wafer Sales Growth Rate

Table North America E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure United States E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure United States E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Canada E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Canada E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Mexico E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Mexico E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Europe E-Chuck for Wafer Sales Growth Rate

Table Europe E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Germany E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Germany E-Chuck for Wafer Revenue (Million USD) (2014-2019)

Figure UK E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure UK E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure France E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure France E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Italy E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Italy E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Russia E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Russia E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Turkey E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Turkey E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Asia-Pacific E-Chuck for Wafer Sales Growth Rate

Table Asia-Pacific E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure China E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure China E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Japan E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Japan E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Korea E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Korea E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Southeast Asia E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Southeast Asia E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Indonesia E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Indonesia E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Thailand E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Thailand E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Malaysia E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Malaysia E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Philippines E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Philippines E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Vietnam E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Vietnam E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure India E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure India E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Australia E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Australia E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure South America E-Chuck for Wafer Sales Growth Rate

Table South America E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure Brazil E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure Brazil E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure Middle East and Africa E-Chuck for Wafer Sales Growth Rate

Table Middle East and Africa E-Chuck for Wafer Sales (K Units), Revenue (Million USD), Price (USD/Unit) and Gross Margin (%)(2014-2019)

Figure North Africa E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure North Africa E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure GCC Countries E-Chuck for Wafer Sales (K Units)(2014-2019)

Figure GCC Countries E-Chuck for Wafer Revenue (Million USD)(2014-2019)

Figure 300 mm Wafer Examples

Figure 200 mm Wafer Examples

Figure Others Examples

Table Global E-Chuck for Wafer Sales (K Units) Comparison by Application (2014-2025)

Table Global E-Chuck for Wafer Sales (K Units) by Application (2014-2019)

Table Global E-Chuck for Wafer Sales Share (%) by Application (2014-2019)

Figure Global E-Chuck for Wafer Sales Market Share (%) by Application (2014-2019)

Figure Global E-Chuck for Wafer Sales Market Share (%) by Application in 2018

Figure Global E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Global E-Chuck for Wafer Revenue (Million USD) and Growth Rate (%) Forecast (2019-2025)

Table Global E-Chuck for Wafer Sales (K Units) Forecast by Regions (2019-2025)

Figure Global E-Chuck for Wafer Sales Market Share (%) Forecast by Regions (2019-2025)

Figure North America E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure North America E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Europe E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Europe E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Asia-Pacific E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Asia-Pacific E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure China E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure China E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Japan E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Japan E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Korea E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Korea E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Southeast Asia E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Southeast Asia E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure India E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure India E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Australia E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Australia E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure South America E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure South America E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure Middle East and Africa E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure Middle East and Africa E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure North Africa E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure North Africa E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Figure GCC Countries E-Chuck for Wafer Sales (K Units) and Growth Rate (%) Forecast (2019-2025)

Figure GCC Countries E-Chuck for Wafer Revenue and Growth Rate (%) Forecast (2019-2025)

Table Global E-Chuck for Wafer Sales (Million USD) Forecast by Type (2019-2025)

Figure Global E-Chuck for Wafer Sales Market Share (%) Forecast by Type (2019-2025)

Table Global E-Chuck for Wafer Revenue (Million USD) Forecast by Type (2019-2025)

Figure Global E-Chuck for Wafer Revenue Market Share (%) Forecast by Type (2019-2025)

Figure Coulomb Type E-Chuck for Wafer Sales Growth Forecast

Figure Johnsen-Rahbek (JR) Type E-Chuck for Wafer Sales Growth Forecast

Table Global E-Chuck for Wafer Sales (K Units) Forecast by Application (2019-2025)

Figure Global E-Chuck for Wafer Sales Forecast by Application (2019-2025)

Figure Global E-Chuck for Wafer Sales (K Units) Forecast in 300 mm Wafer

Figure Global E-Chuck for Wafer Sales (K Units) Forecast in 200 mm Wafer

Table Key Raw Materials Lists

Figure Key Raw Materials Price

Table Raw Materials Key Suppliers Lists

Figure E-Chuck for Wafer Manufacturing Cost Structure

Figure E-Chuck for Wafer Industrial Chain Analysis

Table Distributors List

Table E-Chuck for Wafer Downstream Customers

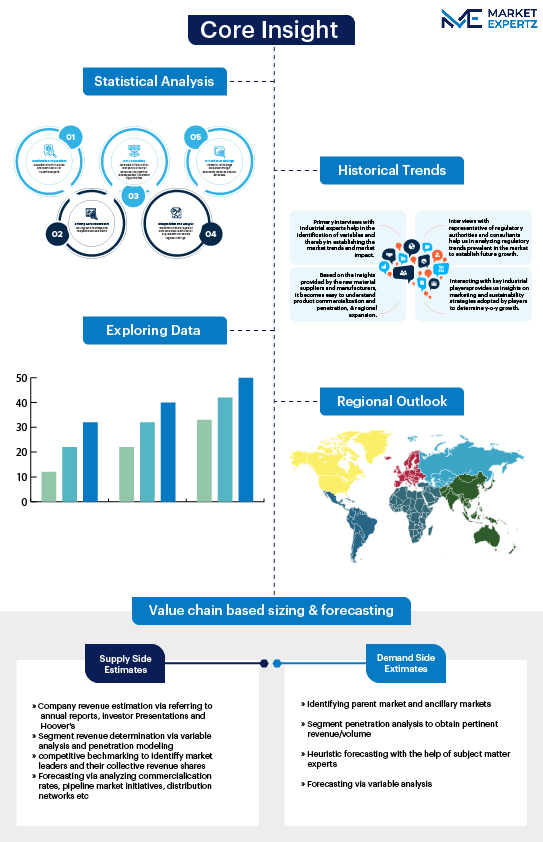

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"