Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 7.91 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The Electronic Potting and Encapsulating Market size is estimated to grow at a CAGR of 5.12% between 2022 and 2032. The market size is forecast to increase by USD 2,567.89 million. The growth of the market depends on several factors, including the increasing demand for electronic components in various industries, the need for protection against environmental factors, and the growing adoption of advanced technologies. Electronic potting and encapsulating refer to the process of enclosing electronic components or assemblies in a protective material to safeguard them from moisture, dust, vibration, and other external factors. This process involves filling the gaps and voids around the components with a liquid or solid material, which then hardens to provide a protective barrier. It ensures the longevity and reliability of electronic devices by preventing damage caused by environmental conditions and mechanical stress.

Electronic Potting and Encapsulating Market Overview:

Drivers:

One of the key factors driving the electronic potting and encapsulating market growth is the increasing demand for electronic components in various industries. With the rapid advancement of technology, electronic components are extensively used in sectors such as automotive, aerospace, consumer electronics, healthcare, and industrial automation. These components are susceptible to damage from moisture, chemicals, temperature variations, and physical stress. Therefore, the need for effective protection through potting and encapsulating processes has become crucial to ensure the durability and performance of electronic devices in these industries.

Moreover, the growing adoption of advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and 5G is further fueling the demand for electronic components. These technologies require reliable and robust electronic devices that can withstand harsh environmental conditions. As a result, the electronic potting and encapsulating market is expected to witness significant growth during the forecast period.

Trends:

A key trend shaping the electronic potting and encapsulating market growth is the development of eco-friendly and sustainable encapsulation materials. With increasing environmental concerns, there is a growing focus on using materials that are non-toxic, recyclable, and have a low carbon footprint. Manufacturers are investing in research and development to develop innovative encapsulation materials that meet these sustainability requirements without compromising on performance and protection.

Additionally, there is a rising demand for miniaturization of electronic devices, which is driving the development of advanced potting and encapsulating techniques. As electronic devices become smaller and more compact, traditional potting and encapsulating methods may not be suitable. Therefore, new techniques such as microencapsulation and nanocoating are being developed to provide effective protection while minimizing the size and weight of the encapsulated components. These advancements in potting and encapsulating technologies are expected to drive market growth during the forecast period.

Restraints:

One of the key challenges hindering the electronic potting and encapsulating market growth is the high cost associated with the process. The materials used for potting and encapsulating, such as epoxy resins and silicone, can be expensive. Additionally, the equipment and machinery required for the process, including dispensing systems and curing ovens, can add to the overall cost. This cost factor may limit the adoption of potting and encapsulating processes, especially in price-sensitive industries.

Furthermore, the potting and encapsulating process can be time-consuming, especially for complex electronic assemblies with multiple components. The curing time of the encapsulation material can vary depending on factors such as temperature and humidity, which can further extend the production time. This time constraint may pose challenges in meeting the demand for electronic devices in a timely manner. Hence, such factors are expected to hinder market growth during the forecast period.

Electronic Potting and Encapsulating Market Segmentation By Application:

The consumer electronics segment is estimated to witness significant growth during the forecast period. With the increasing demand for smartphones, tablets, smartwatches, and other consumer electronic devices, the need for effective protection against moisture, dust, and physical stress has become crucial. Electronic potting and encapsulating processes provide a reliable solution to safeguard the delicate electronic components in these devices, ensuring their longevity and performance.

The automotive segment is another key application area for electronic potting and encapsulating. As vehicles become more technologically advanced, electronic components play a critical role in various systems such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). These components are exposed to harsh environmental conditions, including temperature variations, vibrations, and moisture. Therefore, potting and encapsulating processes are essential to protect them from damage and ensure their reliable operation. The increasing adoption of electric vehicles and autonomous driving technologies is expected to further drive the demand for electronic potting and encapsulating in the automotive sector.

Electronic Potting and Encapsulating Market Segmentation By Type:

The epoxy resin segment is estimated to dominate the electronic potting and encapsulating market during the forecast period. Epoxy resins offer excellent protection against moisture, chemicals, and temperature variations, making them suitable for a wide range of applications. They provide high mechanical strength, good adhesion to various substrates, and excellent electrical insulation properties. These characteristics make epoxy resins a preferred choice for potting and encapsulating electronic components in industries such as automotive, aerospace, and industrial automation.

The silicone segment is another significant type of encapsulation material. Silicone offers flexibility, high thermal stability, and resistance to moisture and chemicals. It is widely used in applications where flexibility and thermal management are critical, such as LED lighting, power electronics, and medical devices. The increasing demand for energy-efficient lighting solutions and the growing adoption of medical electronics are expected to drive the demand for silicone encapsulation in the electronic potting and encapsulating market.

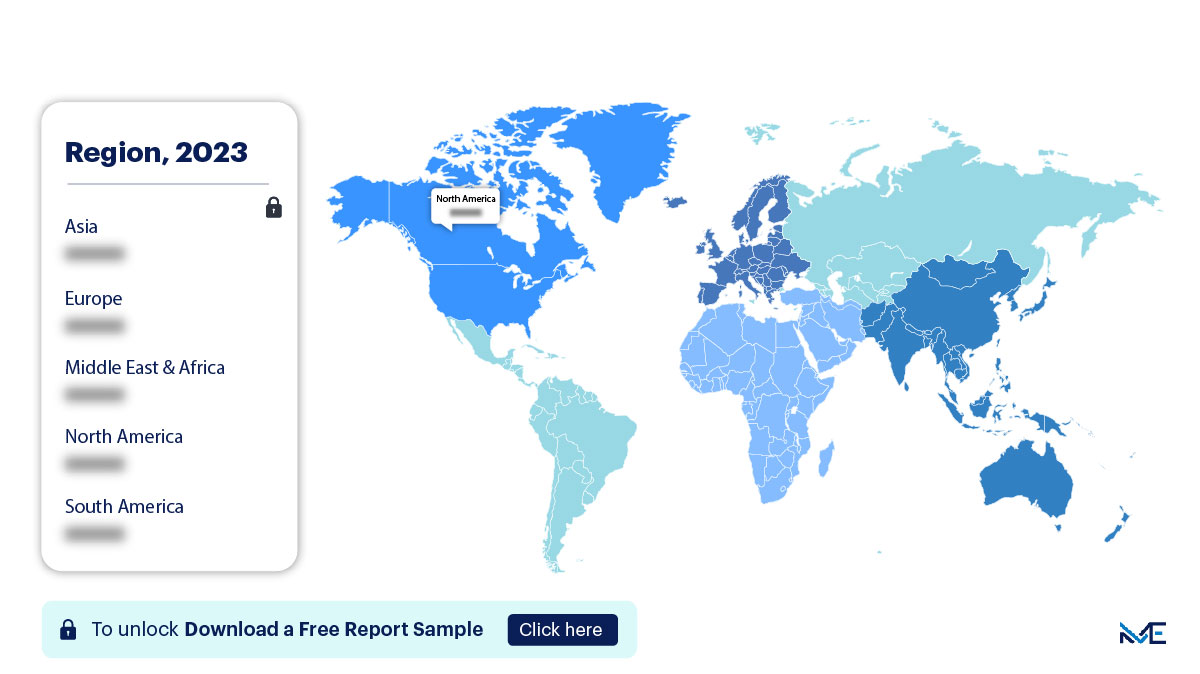

Regional Overview:

Download the report summary now!

Request pdf Sample

North America is estimated to contribute significantly to the growth of the global electronic potting and encapsulating market during the forecast period. The region is home to several prominent electronics manufacturers and technology companies, driving the demand for potting and encapsulating processes. The automotive and aerospace industries in North America also contribute to the market growth, as these sectors extensively use electronic components that require effective protection. Additionally, the region has a strong focus on research and development, leading to technological advancements in potting and encapsulating materials and techniques.

Europe is another key region in the electronic potting and encapsulating market. The presence of major automotive manufacturers and the growing adoption of electric vehicles in countries such as Germany and the United Kingdom drive the demand for potting and encapsulating processes in the region. The aerospace and defense industries in Europe also contribute to the market growth, as these sectors require reliable and durable electronic components for critical applications.

Asia Pacific (APAC) is expected to witness significant growth in the electronic potting and encapsulating market. The region is a manufacturing hub for consumer electronics, automotive, and industrial automation industries. The increasing demand for electronic devices in countries such as China, India, and South Korea drives the need for effective potting and encapsulating processes. Additionally, the rapid growth of the semiconductor industry in APAC further fuels the demand for electronic potting and encapsulating materials and services.

Electronic Potting and Encapsulating Market Customer Landscape:

The electronic potting and encapsulating market industry report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their growth strategies.

Who are the Major Electronic Potting and Encapsulating Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

- Henkel AG & Co. KGaA: The company offers electronic potting and encapsulating materials such as epoxy resins, silicone gels, and polyurethane compounds.

- Dow Inc.: The company offers a wide range of electronic potting and encapsulating materials, including silicone elastomers, epoxy resins, and polyurethane compounds.

- B. Fuller Company: The company provides electronic potting and encapsulating solutions, including epoxy adhesives, silicone sealants, and UV-curable materials.

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

- Henkel AG & Co. KGaA

- Dow Inc.

- H.B. Fuller Company

- 3M Company

- LORD Corporation

- Huntsman Corporation

- Electrolube

- MG Chemicals

- Master Bond Inc.

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- ITW Polymers Sealants North America

- Epoxies, Etc.

- Resin Designs, LLC

- ACC Silicones Ltd.

- Permabond Engineering Adhesives Ltd.

- Panacol-Elosol GmbH

- MG Chemicals Ltd.

- Creative Materials Inc.

- Protavic America Inc.

The competitive landscape of the market features these and other key players, each offering unique solutions to address the diverse needs of industries relying on electronic potting and encapsulating materials.

Segment Overview:

The electronic potting and encapsulating market report offers a comprehensive forecast of market growth, both globally and regionally. It includes an analysis of trends and growth opportunities from 2019 to 2032, covering the following segments:

Application Outlook (USD Million, 2019 - 2032):

- Consumer Electronics

- Automotive Electronics

- Aerospace and Defense

- Medical Devices

- Industrial Electronics

Material Type Outlook (USD Million, 2019 - 2032):

- Epoxy Resins

- Silicone Rubber

- Polyurethane Resins

- Potting Gels

Geography Outlook (USD Million, 2019 - 2032):

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Chile

- Argentina

- Brazil

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Key Benefits for Stakeholders

- Comprehensive Market Analysis- The study meticulously segments the market based on both economic and non-economic criteria, conducting both qualitative and quantitative analyses. This rigorous approach offers a deep understanding of various market segments and sub-segments.

- Accurate Market Valuation- Precise market values in USD Billion are furnished for each segment and sub-segment, facilitating stakeholders in making precise assessments of market opportunities.

- Identification of Growth Prospects- The report pinpoints regions and market segments poised for rapid expansion, as well as those with substantial market share potential. This assists stakeholders in making well-informed strategic decisions.

- Insightful Regional Analysis- The research explores regional factors influencing the market and scrutinizes product or service utilization in diverse geographical areas, enhancing comprehension of regional dynamics.

- Comprehensive Competitive Insight- The report encompasses critical data, including market share of leading players, recent service/product launches, collaborations, expansions, and acquisitions made by profiled companies in the last five years. This provides a holistic view of the competitive landscape.

- Detailed Company Profiles- In-depth profiles of key market participants encompass company overviews, business insights, product benchmarking, and SWOT analyses. This equips stakeholders with the means to evaluate the strengths and weaknesses of these entities.

- Future Market Outlook- The research furnishes an industry perspective on the present and future based on recent developments, enabling stakeholders to anticipate market trends and forthcoming changes.

- Thorough Market Examination- Porter’s five forces analysis is employed in the study to provide a comprehensive examination of the market from multiple angles, including competitive forces and market dynamics.

- Value Chain Insights- The research leverages the Value Chain concept to elucidate the market, offering insights into how products or services traverse the market ecosystem.

- Market Dynamics and Growth Prospects- The study presents current market dynamics and growth prospects for the foreseeable future, empowering stakeholders with invaluable information for strategic decision-making.

Table of Contents

Global Electronic Potting and Encapsulating Market Research Report 2018

1 Electronic Potting and Encapsulating Market Overview

1.1 Product Overview and Scope of Electronic Potting and Encapsulating

1.2 Electronic Potting and Encapsulating Segment by Type (Product Category)

1.2.1 Global Electronic Potting and Encapsulating Production and CAGR (%) Comparison by Type (Product Category)(2013-2025)

1.2.2 Global Electronic Potting and Encapsulating Production Market Share by Type (Product Category) in 2017

1.2.3 Epoxy

1.2.4 Silicones

1.2.5 Polyurethane

1.2.6 Ohers

1.3 Global Electronic Potting and Encapsulating Segment by Application

1.3.1 Electronic Potting and Encapsulating Consumption (Sales) Comparison by Application (2013-2025)

1.3.2 Consumer Electronics

1.3.3 Automotive

1.3.4 Medical

1.3.5 Telecommunications

1.3.6 Others

1.4 Global Electronic Potting and Encapsulating Market by Region (2013-2025)

1.4.1 Global Electronic Potting and Encapsulating Market Size (Value) and CAGR (%) Comparison by Region (2013-2025)

1.4.2 United States Status and Prospect (2013-2025)

1.4.3 EU Status and Prospect (2013-2025)

1.4.4 China Status and Prospect (2013-2025)

1.4.5 Japan Status and Prospect (2013-2025)

1.4.6 South Korea Status and Prospect (2013-2025)

1.4.7 Taiwan Status and Prospect (2013-2025)

1.5 Global Market Size (Value) of Electronic Potting and Encapsulating (2013-2025)

1.5.1 Global Electronic Potting and Encapsulating Revenue Status and Outlook (2013-2025)

1.5.2 Global Electronic Potting and Encapsulating Capacity, Production Status and Outlook (2013-2025)

2 Global Electronic Potting and Encapsulating Market Competition by Manufacturers

2.1 Global Electronic Potting and Encapsulating Capacity, Production and Share by Manufacturers (2013-2018)

2.1.1 Global Electronic Potting and Encapsulating Capacity and Share by Manufacturers (2013-2018)

2.1.2 Global Electronic Potting and Encapsulating Production and Share by Manufacturers (2013-2018)

2.2 Global Electronic Potting and Encapsulating Revenue and Share by Manufacturers (2013-2018)

2.3 Global Electronic Potting and Encapsulating Average Price by Manufacturers (2013-2018)

2.4 Manufacturers Electronic Potting and Encapsulating Manufacturing Base Distribution, Sales Area and Product Type

2.5 Electronic Potting and Encapsulating Market Competitive Situation and Trends

2.5.1 Electronic Potting and Encapsulating Market Concentration Rate

2.5.2 Electronic Potting and Encapsulating Market Share of Top 3 and Top 5 Manufacturers

2.5.3 Mergers & Acquisitions, Expansion

3 Global Electronic Potting and Encapsulating Capacity, Production, Revenue (Value) by Region (2013-2018)

3.1 Global Electronic Potting and Encapsulating Capacity and Market Share by Region (2013-2018)

3.2 Global Electronic Potting and Encapsulating Production and Market Share by Region (2013-2018)

3.3 Global Electronic Potting and Encapsulating Revenue (Value) and Market Share by Region (2013-2018)

3.4 Global Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.5 United States Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.6 EU Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.7 China Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.8 Japan Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.9 South Korea Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

3.10 Taiwan Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

4 Global Electronic Potting and Encapsulating Supply (Production), Consumption, Export, Import by Region (2013-2018)

4.1 Global Electronic Potting and Encapsulating Consumption by Region (2013-2018)

4.2 United States Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

4.3 EU Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

4.4 China Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

4.5 Japan Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

4.6 South Korea Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

4.7 Taiwan Electronic Potting and Encapsulating Production, Consumption, Export, Import (2013-2018)

5 Global Electronic Potting and Encapsulating Production, Revenue (Value), Price Trend by Type

5.1 Global Electronic Potting and Encapsulating Production and Market Share by Type (2013-2018)

5.2 Global Electronic Potting and Encapsulating Revenue and Market Share by Type (2013-2018)

5.3 Global Electronic Potting and Encapsulating Price by Type (2013-2018)

5.4 Global Electronic Potting and Encapsulating Production Growth by Type (2013-2018)

6 Global Electronic Potting and Encapsulating Market Analysis by Application

6.1 Global Electronic Potting and Encapsulating Consumption and Market Share by Application (2013-2018)

6.2 Global Electronic Potting and Encapsulating Consumption Growth Rate by Application (2013-2018)

6.3 Market Drivers and Opportunities

6.3.1 Potential Applications

6.3.2 Emerging Markets/Countries

7 Global Electronic Potting and Encapsulating Manufacturers Profiles/Analysis

7.1 Henkel

7.1.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.1.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.1.2.1 Product A

7.1.2.2 Product B

7.1.3 Henkel Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.1.4 Main Business/Business Overview

7.2 Dow Corning

7.2.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.2.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.2.2.1 Product A

7.2.2.2 Product B

7.2.3 Dow Corning Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.2.4 Main Business/Business Overview

7.3 Hitachi Chemical

7.3.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.3.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.3.2.1 Product A

7.3.2.2 Product B

7.3.3 Hitachi Chemical Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.3.4 Main Business/Business Overview

7.4 LORD Corporation

7.4.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.4.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.4.2.1 Product A

7.4.2.2 Product B

7.4.3 LORD Corporation Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.4.4 Main Business/Business Overview

7.5 Huntsman Corporation

7.5.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.5.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.5.2.1 Product A

7.5.2.2 Product B

7.5.3 Huntsman Corporation Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.5.4 Main Business/Business Overview

7.6 ITW Engineered Polymers

7.6.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.6.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.6.2.1 Product A

7.6.2.2 Product B

7.6.3 ITW Engineered Polymers Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.6.4 Main Business/Business Overview

7.7 3M

7.7.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.7.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.7.2.1 Product A

7.7.2.2 Product B

7.7.3 3M Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.7.4 Main Business/Business Overview

7.8 H.B. Fuller

7.8.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.8.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.8.2.1 Product A

7.8.2.2 Product B

7.8.3 H.B. Fuller Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.8.4 Main Business/Business Overview

7.9 John C. Dolph

7.9.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.9.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.9.2.1 Product A

7.9.2.2 Product B

7.9.3 John C. Dolph Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.9.4 Main Business/Business Overview

7.10 Master Bond

7.10.1 Company Basic Information, Manufacturing Base, Sales Area and Its Competitors

7.10.2 Electronic Potting and Encapsulating Product Category, Application and Specification

7.10.2.1 Product A

7.10.2.2 Product B

7.10.3 Master Bond Electronic Potting and Encapsulating Capacity, Production, Revenue, Price and Gross Margin (2013-2018)

7.10.4 Main Business/Business Overview

7.11 ACC Silicones

7.12 Epic Resins

7.13 Plasma Ruggedized Solutions

8 Electronic Potting and Encapsulating Manufacturing Cost Analysis

8.1 Electronic Potting and Encapsulating Key Raw Materials Analysis

8.1.1 Key Raw Materials

8.1.2 Price Trend of Key Raw Materials

8.1.3 Key Suppliers of Raw Materials

8.1.4 Market Concentration Rate of Raw Materials

8.2 Proportion of Manufacturing Cost Structure

8.2.1 Raw Materials

8.2.2 Labor Cost

8.2.3 Manufacturing Expenses

8.3 Manufacturing Process Analysis of Electronic Potting and Encapsulating

9 Industrial Chain, Sourcing Strategy and Downstream Buyers

9.1 Electronic Potting and Encapsulating Industrial Chain Analysis

9.2 Upstream Raw Materials Sourcing

9.3 Raw Materials Sources of Electronic Potting and Encapsulating Major Manufacturers in 2017

9.4 Downstream Buyers

10 Marketing Strategy Analysis, Distributors/Traders

10.1 Marketing Channel

10.1.1 Direct Marketing

10.1.2 Indirect Marketing

10.1.3 Marketing Channel Development Trend

10.2 Market Positioning

10.2.1 Pricing Strategy

10.2.2 Brand Strategy

10.2.3 Target Client

10.3 Distributors/Traders List

11 Market Effect Factors Analysis

11.1 Technology Progress/Risk

11.1.1 Substitutes Threat

11.1.2 Technology Progress in Related Industry

11.2 Consumer Needs/Customer Preference Change

11.3 Economic/Political Environmental Change

12 Global Electronic Potting and Encapsulating Market Forecast (2018-2025)

12.1 Global Electronic Potting and Encapsulating Capacity, Production, Revenue Forecast (2018-2025)

12.1.1 Global Electronic Potting and Encapsulating Capacity, Production and Growth Rate Forecast (2018-2025)

12.1.2 Global Electronic Potting and Encapsulating Revenue and Growth Rate Forecast (2018-2025)

12.1.3 Global Electronic Potting and Encapsulating Price and Trend Forecast (2018-2025)

12.2 Global Electronic Potting and Encapsulating Production, Consumption , Import and Export Forecast by Region (2018-2025)

12.2.1 United States Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.2.2 EU Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.2.3 China Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.2.4 Japan Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.2.5 South Korea Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.2.6 Taiwan Electronic Potting and Encapsulating Production, Revenue, Consumption, Export and Import Forecast (2018-2025)

12.3 Global Electronic Potting and Encapsulating Production, Revenue and Price Forecast by Type (2018-2025)

12.4 Global Electronic Potting and Encapsulating Consumption Forecast by Application (2018-2025)

13 Research Findings and Conclusion

14 Appendix

14.1 Methodology/Research Approach

14.1.1 Research Programs/Design

14.1.2 Market Size Estimation

14.1.3 Market Breakdown and Data Triangulation

14.2 Data Source

14.2.1 Secondary Sources

14.2.2 Primary Sources

14.3 Disclaimer

List of Tables and Figures

Figure Picture of Electronic Potting and Encapsulating

Figure Global Electronic Potting and Encapsulating Production (K MT) and CAGR (%) Comparison by Types (Product Category) (2013-2025)

Figure Global Electronic Potting and Encapsulating Production Market Share by Types (Product Category) in 2017

Figure Product Picture of Epoxy

Table Major Manufacturers of Epoxy

Figure Product Picture of Silicones

Table Major Manufacturers of Silicones

Figure Product Picture of Polyurethane

Table Major Manufacturers of Polyurethane

Figure Product Picture of Ohers

Table Major Manufacturers of Ohers

Figure Global Electronic Potting and Encapsulating Consumption (K MT) by Applications (2013-2025)

Figure Global Electronic Potting and Encapsulating Consumption Market Share by Applications in 2017

Figure Consumer Electronics Examples

Table Key Downstream Customer in Consumer Electronics

Figure Automotive Examples

Table Key Downstream Customer in Automotive

Figure Medical Examples

Table Key Downstream Customer in Medical

Figure Telecommunications Examples

Table Key Downstream Customer in Telecommunications

Figure Others Examples

Table Key Downstream Customer in Others

Figure Global Electronic Potting and Encapsulating Market Size (Million USD), Comparison (K MT) and CAGR (%) by Regions (2013-2025)

Figure United States Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure EU Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure China Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure Japan Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure South Korea Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure Taiwan Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate (2013-2025)

Figure Global Electronic Potting and Encapsulating Revenue (Million USD) Status and Outlook (2013-2025)

Figure Global Electronic Potting and Encapsulating Capacity, Production (K MT) Status and Outlook (2013-2025)

Figure Global Electronic Potting and Encapsulating Major Players Product Capacity (K MT) (2013-2018)

Table Global Electronic Potting and Encapsulating Capacity (K MT) of Key Manufacturers (2013-2018)

Table Global Electronic Potting and Encapsulating Capacity Market Share of Key Manufacturers (2013-2018)

Figure Global Electronic Potting and Encapsulating Capacity (K MT) of Key Manufacturers in 2017

Figure Global Electronic Potting and Encapsulating Capacity (K MT) of Key Manufacturers in 2018

Figure Global Electronic Potting and Encapsulating Major Players Product Production (K MT) (2013-2018)

Table Global Electronic Potting and Encapsulating Production (K MT) of Key Manufacturers (2013-2018)

Table Global Electronic Potting and Encapsulating Production Share by Manufacturers (2013-2018)

Figure 2017 Electronic Potting and Encapsulating Production Share by Manufacturers

Figure 2017 Electronic Potting and Encapsulating Production Share by Manufacturers

Figure Global Electronic Potting and Encapsulating Major Players Product Revenue (Million USD) (2013-2018)

Table Global Electronic Potting and Encapsulating Revenue (Million USD) by Manufacturers (2013-2018)

Table Global Electronic Potting and Encapsulating Revenue Share by Manufacturers (2013-2018)

Table 2017 Global Electronic Potting and Encapsulating Revenue Share by Manufacturers

Table 2018 Global Electronic Potting and Encapsulating Revenue Share by Manufacturers

Table Global Market Electronic Potting and Encapsulating Average Price (USD/MT) of Key Manufacturers (2013-2018)

Figure Global Market Electronic Potting and Encapsulating Average Price (USD/MT) of Key Manufacturers in 2017

Table Manufacturers Electronic Potting and Encapsulating Manufacturing Base Distribution and Sales Area

Table Manufacturers Electronic Potting and Encapsulating Product Category

Figure Electronic Potting and Encapsulating Market Share of Top 3 Manufacturers

Figure Electronic Potting and Encapsulating Market Share of Top 5 Manufacturers

Table Global Electronic Potting and Encapsulating Capacity (K MT) by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Capacity Market Share by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Capacity Market Share by Region (2013-2018)

Figure 2017 Global Electronic Potting and Encapsulating Capacity Market Share by Region

Table Global Electronic Potting and Encapsulating Production by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Production (K MT) by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Production Market Share by Region (2013-2018)

Figure 2017 Global Electronic Potting and Encapsulating Production Market Share by Region

Table Global Electronic Potting and Encapsulating Revenue (Million USD) by Region (2013-2018)

Table Global Electronic Potting and Encapsulating Revenue Market Share by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Revenue Market Share by Region (2013-2018)

Table 2017 Global Electronic Potting and Encapsulating Revenue Market Share by Region

Figure Global Electronic Potting and Encapsulating Capacity, Production (K MT) and Growth Rate (2013-2018)

Table Global Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table United States Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table EU Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table China Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table Japan Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table South Korea Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table Taiwan Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Table Global Electronic Potting and Encapsulating Consumption (K MT) Market by Region (2013-2018)

Table Global Electronic Potting and Encapsulating Consumption Market Share by Region (2013-2018)

Figure Global Electronic Potting and Encapsulating Consumption Market Share by Region (2013-2018)

Figure 2017 Global Electronic Potting and Encapsulating Consumption (K MT) Market Share by Region

Table United States Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table EU Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table China Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table Japan Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table South Korea Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table Taiwan Electronic Potting and Encapsulating Production, Consumption, Import & Export (K MT) (2013-2018)

Table Global Electronic Potting and Encapsulating Production (K MT) by Type (2013-2018)

Table Global Electronic Potting and Encapsulating Production Share by Type (2013-2018)

Figure Production Market Share of Electronic Potting and Encapsulating by Type (2013-2018)

Figure 2017 Production Market Share of Electronic Potting and Encapsulating by Type

Table Global Electronic Potting and Encapsulating Revenue (Million USD) by Type (2013-2018)

Table Global Electronic Potting and Encapsulating Revenue Share by Type (2013-2018)

Figure Production Revenue Share of Electronic Potting and Encapsulating by Type (2013-2018)

Figure 2017 Revenue Market Share of Electronic Potting and Encapsulating by Type

Table Global Electronic Potting and Encapsulating Price (USD/MT) by Type (2013-2018)

Figure Global Electronic Potting and Encapsulating Production Growth by Type (2013-2018)

Table Global Electronic Potting and Encapsulating Consumption (K MT) by Application (2013-2018)

Table Global Electronic Potting and Encapsulating Consumption Market Share by Application (2013-2018)

Figure Global Electronic Potting and Encapsulating Consumption Market Share by Applications (2013-2018)

Figure Global Electronic Potting and Encapsulating Consumption Market Share by Application in 2017

Table Global Electronic Potting and Encapsulating Consumption Growth Rate by Application (2013-2018)

Figure Global Electronic Potting and Encapsulating Consumption Growth Rate by Application (2013-2018)

Table Henkel Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table Henkel Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure Henkel Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure Henkel Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure Henkel Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table Dow Corning Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table Dow Corning Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure Dow Corning Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure Dow Corning Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure Dow Corning Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table Hitachi Chemical Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table Hitachi Chemical Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure Hitachi Chemical Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure Hitachi Chemical Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure Hitachi Chemical Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table LORD Corporation Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table LORD Corporation Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure LORD Corporation Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure LORD Corporation Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure LORD Corporation Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table Huntsman Corporation Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table Huntsman Corporation Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure Huntsman Corporation Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure Huntsman Corporation Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure Huntsman Corporation Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table ITW Engineered Polymers Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table ITW Engineered Polymers Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure ITW Engineered Polymers Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure ITW Engineered Polymers Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure ITW Engineered Polymers Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table 3M Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table 3M Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure 3M Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure 3M Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure 3M Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table H.B. Fuller Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table H.B. Fuller Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure H.B. Fuller Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure H.B. Fuller Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure H.B. Fuller Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table John C. Dolph Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table John C. Dolph Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure John C. Dolph Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure John C. Dolph Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure John C. Dolph Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table Master Bond Basic Information, Manufacturing Base, Sales Area and Its Competitors

Table Master Bond Electronic Potting and Encapsulating Capacity, Production (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2013-2018)

Figure Master Bond Electronic Potting and Encapsulating Production Growth Rate (2013-2018)

Figure Master Bond Electronic Potting and Encapsulating Production Market Share (2013-2018)

Figure Master Bond Electronic Potting and Encapsulating Revenue Market Share (2013-2018)

Table Production Base and Market Concentration Rate of Raw Material

Figure Price Trend of Key Raw Materials

Table Key Suppliers of Raw Materials

Figure Manufacturing Cost Structure of Electronic Potting and Encapsulating

Figure Manufacturing Process Analysis of Electronic Potting and Encapsulating

Figure Electronic Potting and Encapsulating Industrial Chain Analysis

Table Raw Materials Sources of Electronic Potting and Encapsulating Major Manufacturers in 2017

Table Major Buyers of Electronic Potting and Encapsulating

Table Distributors/Traders List

Figure Global Electronic Potting and Encapsulating Capacity, Production (K MT) and Growth Rate Forecast (2018-2025)

Figure Global Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Figure Global Electronic Potting and Encapsulating Price (Million USD) and Trend Forecast (2018-2025)

Table Global Electronic Potting and Encapsulating Production (K MT) Forecast by Region (2018-2025)

Figure Global Electronic Potting and Encapsulating Production Market Share Forecast by Region (2018-2025)

Table Global Electronic Potting and Encapsulating Consumption (K MT) Forecast by Region (2018-2025)

Figure Global Electronic Potting and Encapsulating Consumption Market Share Forecast by Region (2018-2025)

Figure United States Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure United States Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table United States Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Figure EU Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure EU Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table EU Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Figure China Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure China Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table China Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Figure Japan Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure Japan Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table Japan Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Figure South Korea Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure South Korea Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table South Korea Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Figure Taiwan Electronic Potting and Encapsulating Production (K MT) and Growth Rate Forecast (2018-2025)

Figure Taiwan Electronic Potting and Encapsulating Revenue (Million USD) and Growth Rate Forecast (2018-2025)

Table Taiwan Electronic Potting and Encapsulating Production, Consumption, Export and Import (K MT) Forecast (2018-2025)

Table Global Electronic Potting and Encapsulating Production (K MT) Forecast by Type (2018-2025)

Figure Global Electronic Potting and Encapsulating Production (K MT) Forecast by Type (2018-2025)

Table Global Electronic Potting and Encapsulating Revenue (Million USD) Forecast by Type (2018-2025)

Figure Global Electronic Potting and Encapsulating Revenue Market Share Forecast by Type (2018-2025)

Table Global Electronic Potting and Encapsulating Price Forecast by Type (2018-2025)

Table Global Electronic Potting and Encapsulating Consumption (K MT) Forecast by Application (2018-2025)

Figure Global Electronic Potting and Encapsulating Consumption (K MT) Forecast by Application (2018-2025)

Table Research Programs/Design for This Report

Figure Bottom-up and Top-down Approaches for This Report

Figure Data Triangulation

Table Key Data Information from Secondary Sources

Table Key Data Information from Primary Source

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"