Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 5.84 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The High Performance Engineering Plastics Market is poised for remarkable growth, projected to achieve a CAGR of 6.78% between 2022 and 2032. The market's value is forecasted to expand by USD 23,516.87 million. This growth can be attributed to various factors, including the increasing demand for lightweight and durable materials in various industries, the expansion of automotive and aerospace sectors, and the growing emphasis on sustainable solutions. High-performance engineering plastics, known for their exceptional mechanical properties and resistance to extreme conditions, are widely utilized in diverse applications.

High Performance Engineering Plastics Market Overview:

Drivers:

The automotive industry's shift towards lightweighting for improved fuel efficiency and reduced emissions is a significant factor driving the adoption of high-performance engineering plastics. Similarly, the aerospace sector's focus on reducing aircraft weight while maintaining safety standards has led to increased use of these materials in aircraft components.

Trends:

Furthermore, advancements in additive manufacturing (3D printing) technology are enabling the production of complex shapes and designs using high-performance engineering plastics. This trend is particularly relevant in industries like aerospace, where intricate and customized components are required.

Restraints:

Additionally, issues related to recycling and disposal of high-performance engineering plastics pose challenges. These plastics are often less recyclable compared to other materials, and proper disposal methods are required to minimize environmental impact.

High Performance Engineering Plastics Market Segmentation:

Polyamide (PA) Plastics: Polyamide plastics, commonly known as nylon, are extensively used in engineering applications due to their excellent mechanical properties, chemical resistance, and durability. They find applications in automotive, electronics, consumer goods, and industrial sectors.

Polyetheretherketone (PEEK) Plastics: PEEK plastics offer exceptional temperature and chemical resistance, making them suitable for high-performance applications in aerospace, automotive, medical devices, and oil and gas industries.

Polyphenylene Sulfide (PPS) Plastics: PPS plastics exhibit excellent chemical resistance and dimensional stability, making them suitable for applications requiring exposure to harsh environments, such as automotive components and electrical connectors.

Polyimide (PI) Plastics: Polyimide plastics are known for their high-temperature resistance, making them ideal for aerospace, electronics, and industrial applications where thermal stability is crucial.

Liquid Crystal Polymers (LCP) Plastics: LCP plastics offer excellent electrical properties and are widely used in electronics, telecommunications, and automotive industries for applications like connectors, switches, and insulators.

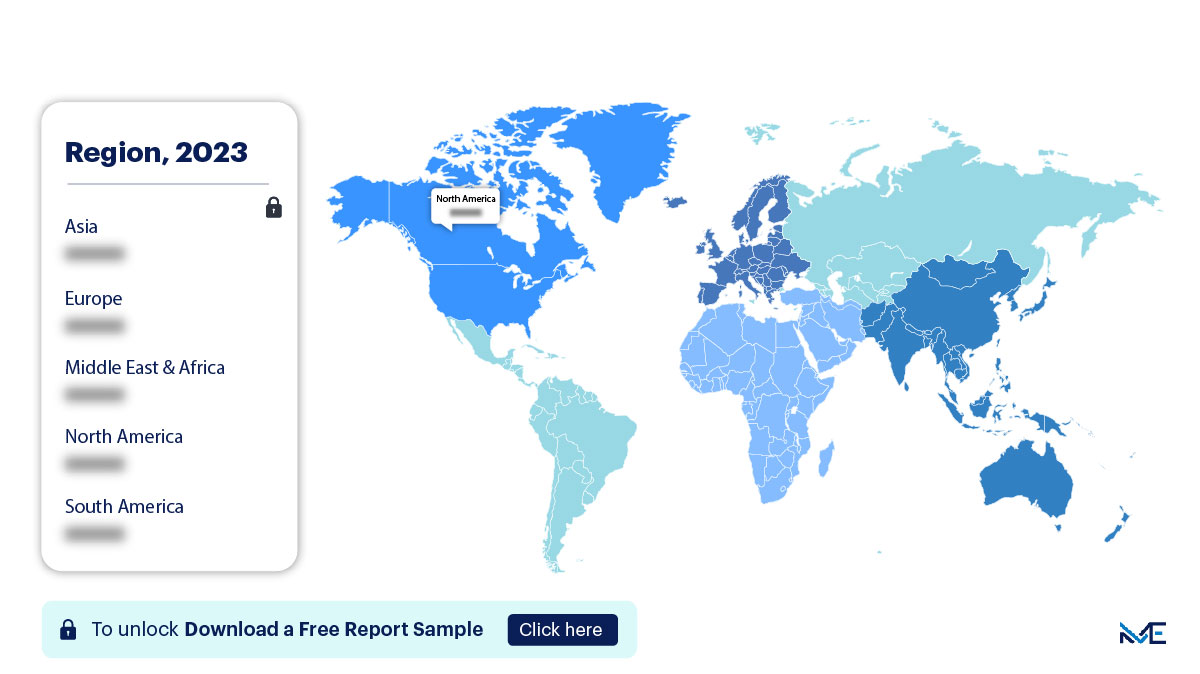

Regional Overview:

Download the report summary now!

Request pdf Sample

North America: North America is anticipated to be a significant market for high-performance engineering plastics, driven by the robust automotive and aerospace sectors. The United States and Canada are likely to contribute prominently to the market's growth, with increasing demand for lightweight and high-strength materials.

Europe: Europe's strong manufacturing base, particularly in automotive, aerospace, and industrial sectors, supports the growth of the high-performance engineering plastics market. Countries like Germany, France, and the United Kingdom are expected to drive demand for these materials.

APAC: Asia-Pacific is witnessing rapid industrialization and urbanization, driving the demand for high-performance engineering plastics across various applications. China and India are emerging as key markets due to their expanding automotive, electronics, and infrastructure sectors.

South America: South America's growing automotive and construction industries contribute to the demand for high-performance engineering plastics. Countries like Brazil and Argentina are likely to witness increased adoption of these materials.

Middle East & Africa: The Middle East & Africa region's infrastructure development and industrial growth drive the demand for high-performance engineering plastics, particularly in construction, oil and gas, and automotive sectors.

High Performance Engineering Plastics Market Customer Landscape: Understanding customer preferences and adoption patterns is crucial for companies in the high-performance engineering plastics market. The report provides insights into the adoption lifecycle of these materials, from early innovators to late adopters. It also analyzes the criteria influencing customer purchasing decisions, including mechanical properties, temperature resistance, industry regulations, and cost considerations.

Major High Performance Engineering Plastics Market Companies: Companies in the high-performance engineering plastics market are adopting strategies to capitalize on growth opportunities:

- PolyPlast Innovations Inc.: PolyPlast Innovations offers a range of high-performance engineering plastics, including PEEK, PPS, and LCP variants, catering to diverse industry needs.

- ThermoTech Solutions: ThermoTech Solutions specializes in providing advanced polyamide and polyimide plastics for critical applications in aerospace, electronics, and industrial sectors.

- Nylonix Polymers Ltd.: Nylonix Polymers focuses on innovative nylon-based solutions, offering enhanced polyamide plastics with superior mechanical and thermal properties.

The competitive landscape analysis in the report includes detailed assessments of 20 market companies, categorizing them based on their strengths, market presence, and specialization.

- DuPont

- BASF SE

- Solvay SA

- Covestro AG

- DSM Engineering Plastics

- SABIC

- Evonik Industries AG

- Mitsubishi Engineering-Plastics Corporation

- Celanese Corporation

- LANXESS AG

- Victrex plc

- Arkema SA

- Polyplastics Co., Ltd.

- Asahi Kasei Corporation

- Toray Industries, Inc.

- Teijin Limited

- Sumitomo Chemical Co., Ltd.

- RadiciGroup

- RTP Company

- Ensinger GmbH

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Segment Overview:

- Application Outlook (USD Million, 2019 - 2032):

- Automotive

- Aerospace

- Electronics & Electrical

- Industrial & Machinery

- Healthcare & Medical Devices

- Consumer Goods

- Others

- Plastics Type Outlook (USD Million, 2019 - 2032):

- Polyamide (PA)

- Polyetheretherketone (PEEK)

- Polyphenylene Sulfide (PPS)

- Polyimide (PI)

- Liquid Crystal Polymers (LCP)

- Others

- Geography Outlook (USD Million, 2019 - 2032):

- North America

- United States

- Canada

- Europe

- United Kingdom

- Germany

- France

- Rest of Europe

- Asia-Pacific

- China

- India

- South America

- Brazil

- Argentina

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Table of Contents

United States High Performance Engineering Plastics Market Report 2017

1 High Performance Engineering Plastics Overview

1.1 Product Overview and Scope of High Performance Engineering Plastics

1.2 Classification of High Performance Engineering Plastics by Product Category

1.2.1 United States High Performance Engineering Plastics Market Size (Sales Volume) Comparison by Type (2012-2022)

1.2.2 United States High Performance Engineering Plastics Market Size (Sales Volume) Market Share by Type (Product Category) in 2016

1.2.3 PPS

1.2.4 PAR

1.2.5 LCP

1.2.6 PSU

1.2.7 PES

1.2.8 P1

1.2.9 Others

1.3 United States High Performance Engineering Plastics Market by Application/End Users

1.3.1 United States High Performance Engineering Plastics Market Size (Consumption) and Market Share Comparison by Application (2012-2022)

1.3.2 Automotive Industry

1.3.3 Machinery Equipment

1.3.4 Electrical & Electronics

1.3.5 Others

1.4 United States High Performance Engineering Plastics Market by Region

1.4.1 United States High Performance Engineering Plastics Market Size (Value) Comparison by Region (2012-2022)

1.4.2 The West High Performance Engineering Plastics Status and Prospect (2012-2022)

1.4.3 Southwest High Performance Engineering Plastics Status and Prospect (2012-2022)

1.4.4 The Middle Atlantic High Performance Engineering Plastics Status and Prospect (2012-2022)

1.4.5 New England High Performance Engineering Plastics Status and Prospect (2012-2022)

1.4.6 The South High Performance Engineering Plastics Status and Prospect (2012-2022)

1.4.7 The Midwest High Performance Engineering Plastics Status and Prospect (2012-2022)

1.5 United States Market Size (Value and Volume) of High Performance Engineering Plastics (2012-2022)

1.5.1 United States High Performance Engineering Plastics Sales and Growth Rate (2012-2022)

1.5.2 United States High Performance Engineering Plastics Revenue and Growth Rate (2012-2022)

2 United States High Performance Engineering Plastics Market Competition by Players/Suppliers

2.1 United States High Performance Engineering Plastics Sales and Market Share of Key Players/Suppliers (2012-2017)

2.2 United States High Performance Engineering Plastics Revenue and Share by Players/Suppliers (2012-2017)

2.3 United States High Performance Engineering Plastics Average Price by Players/Suppliers (2012-2017)

2.4 United States High Performance Engineering Plastics Market Competitive Situation and Trends

2.4.1 United States High Performance Engineering Plastics Market Concentration Rate

2.4.2 United States High Performance Engineering Plastics Market Share of Top 3 and Top 5 Players/Suppliers

2.4.3 Mergers & Acquisitions, Expansion in United States Market

2.5 United States Players/Suppliers High Performance Engineering Plastics Manufacturing Base Distribution, Sales Area, Product Type

3 United States High Performance Engineering Plastics Sales (Volume) and Revenue (Value) by Region (2012-2017)

3.1 United States High Performance Engineering Plastics Sales and Market Share by Region (2012-2017)

3.2 United States High Performance Engineering Plastics Revenue and Market Share by Region (2012-2017)

3.3 United States High Performance Engineering Plastics Price by Region (2012-2017)

4 United States High Performance Engineering Plastics Sales (Volume) and Revenue (Value) by Type (Product Category) (2012-2017)

4.1 United States High Performance Engineering Plastics Sales and Market Share by Type (Product Category) (2012-2017)

4.2 United States High Performance Engineering Plastics Revenue and Market Share by Type (2012-2017)

4.3 United States High Performance Engineering Plastics Price by Type (2012-2017)

4.4 United States High Performance Engineering Plastics Sales Growth Rate by Type (2012-2017)

5 United States High Performance Engineering Plastics Sales (Volume) by Application (2012-2017)

5.1 United States High Performance Engineering Plastics Sales and Market Share by Application (2012-2017)

5.2 United States High Performance Engineering Plastics Sales Growth Rate by Application (2012-2017)

5.3 Market Drivers and Opportunities

6 United States High Performance Engineering Plastics Players/Suppliers Profiles and Sales Data

6.1 BASF

6.1.1 Company Basic Information, Manufacturing Base and Competitors

6.1.2 High Performance Engineering Plastics Product Category, Application and Specification

6.1.2.1 Product A

6.1.2.2 Product B

6.1.3 BASF High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.1.4 Main Business/Business Overview

6.2 Asahi Kasei

6.2.2 High Performance Engineering Plastics Product Category, Application and Specification

6.2.2.1 Product A

6.2.2.2 Product B

6.2.3 Asahi Kasei High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.2.4 Main Business/Business Overview

6.3 DSM

6.3.2 High Performance Engineering Plastics Product Category, Application and Specification

6.3.2.1 Product A

6.3.2.2 Product B

6.3.3 DSM High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.3.4 Main Business/Business Overview

6.4 Invista

6.4.2 High Performance Engineering Plastics Product Category, Application and Specification

6.4.2.1 Product A

6.4.2.2 Product B

6.4.3 Invista High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.4.4 Main Business/Business Overview

6.5 Ascend

6.5.2 High Performance Engineering Plastics Product Category, Application and Specification

6.5.2.1 Product A

6.5.2.2 Product B

6.5.3 Ascend High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.5.4 Main Business/Business Overview

6.6 Solvay

6.6.2 High Performance Engineering Plastics Product Category, Application and Specification

6.6.2.1 Product A

6.6.2.2 Product B

6.6.3 Solvay High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.6.4 Main Business/Business Overview

6.7 Dupont

6.7.2 High Performance Engineering Plastics Product Category, Application and Specification

6.7.2.1 Product A

6.7.2.2 Product B

6.7.3 Dupont High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.7.4 Main Business/Business Overview

6.8 Radici Group

6.8.2 High Performance Engineering Plastics Product Category, Application and Specification

6.8.2.1 Product A

6.8.2.2 Product B

6.8.3 Radici Group High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.8.4 Main Business/Business Overview

6.9 Shenma

6.9.2 High Performance Engineering Plastics Product Category, Application and Specification

6.9.2.1 Product A

6.9.2.2 Product B

6.9.3 Shenma High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.9.4 Main Business/Business Overview

6.10 Hua Yang

6.10.2 High Performance Engineering Plastics Product Category, Application and Specification

6.10.2.1 Product A

6.10.2.2 Product B

6.10.3 Hua Yang High Performance Engineering Plastics Sales, Revenue, Price and Gross Margin (2012-2017)

6.10.4 Main Business/Business Overview

7 High Performance Engineering Plastics Manufacturing Cost Analysis

7.1 High Performance Engineering Plastics Key Raw Materials Analysis

7.1.1 Key Raw Materials

7.1.2 Price Trend of Key Raw Materials

7.1.3 Key Suppliers of Raw Materials

7.1.4 Market Concentration Rate of Raw Materials

7.2 Proportion of Manufacturing Cost Structure

7.2.1 Raw Materials

7.2.2 Labor Cost

7.2.3 Manufacturing Expenses

7.3 Manufacturing Process Analysis of High Performance Engineering Plastics

8 Industrial Chain, Sourcing Strategy and Downstream Buyers

8.1 High Performance Engineering Plastics Industrial Chain Analysis

8.2 Upstream Raw Materials Sourcing

8.3 Raw Materials Sources of High Performance Engineering Plastics Major Manufacturers in 2016

8.4 Downstream Buyers

9 Marketing Strategy Analysis, Distributors/Traders

9.1 Marketing Channel

9.1.1 Direct Marketing

9.1.2 Indirect Marketing

9.1.3 Marketing Channel Development Trend

9.2 Market Positioning

9.2.1 Pricing Strategy

9.2.2 Brand Strategy

9.2.3 Target Client

9.3 Distributors/Traders List

10 Market Effect Factors Analysis

10.1 Technology Progress/Risk

10.1.1 Substitutes Threat

10.1.2 Technology Progress in Related Industry

10.2 Consumer Needs/Customer Preference Change

10.3 Economic/Political Environmental Change

11 United States High Performance Engineering Plastics Market Size (Value and Volume) Forecast (2017-2022)

11.1 United States High Performance Engineering Plastics Sales Volume, Revenue Forecast (2017-2022)

11.2 United States High Performance Engineering Plastics Sales Volume Forecast by Type (2017-2022)

11.3 United States High Performance Engineering Plastics Sales Volume Forecast by Application (2017-2022)

11.4 United States High Performance Engineering Plastics Sales Volume Forecast by Region (2017-2022)

12 Research Findings and Conclusion

13 Appendix

13.1 Methodology/Research Approach

13.1.1 Research Programs/Design

13.1.2 Market Size Estimation

13.1.3 Market Breakdown and Data Triangulation

13.2 Data Source

13.2.1 Secondary Sources

13.2.2 Primary Sources

13.3 Disclaimer

List of Tables and Figures

Figure Product Picture of High Performance Engineering Plastics

Figure United States High Performance Engineering Plastics Market Size (K MT) by Type (2012-2022)

Figure United States High Performance Engineering Plastics Sales Volume Market Share by Type (Product Category) in 2016

Figure PPS Product Picture

Figure PAR Product Picture

Figure LCP Product Picture

Figure PSU Product Picture

Figure PES Product Picture

Figure P1 Product Picture

Figure Others Product Picture

Figure United States High Performance Engineering Plastics Market Size (K MT) by Application (2012-2022)

Figure United States Sales Market Share of High Performance Engineering Plastics by Application in 2016

Figure Automotive Industry Examples

Table Key Downstream Customer in Automotive Industry

Figure Machinery Equipment Examples

Table Key Downstream Customer in Machinery Equipment

Figure Electrical & Electronics Examples

Table Key Downstream Customer in Electrical & Electronics

Figure Others Examples

Table Key Downstream Customer in Others

Figure United States High Performance Engineering Plastics Market Size (Million USD) by Region (2012-2022)

Figure The West High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure Southwest High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure The Middle Atlantic High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure New England High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure The South of US High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure The Midwest High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure United States High Performance Engineering Plastics Sales (K MT) and Growth Rate (2012-2022)

Figure United States High Performance Engineering Plastics Revenue (Million USD) and Growth Rate (2012-2022)

Figure United States High Performance Engineering Plastics Market Major Players Product Sales Volume (K MT) (2012-2017)

Table United States High Performance Engineering Plastics Sales (K MT) of Key Players/Suppliers (2012-2017)

Table United States High Performance Engineering Plastics Sales Share by Players/Suppliers (2012-2017)

Figure 2016 United States High Performance Engineering Plastics Sales Share by Players/Suppliers

Figure 2017 United States High Performance Engineering Plastics Sales Share by Players/Suppliers

Figure United States High Performance Engineering Plastics Market Major Players Product Revenue (Million USD) (2012-2017)

Table United States High Performance Engineering Plastics Revenue (Million USD) by Players/Suppliers (2012-2017)

Table United States High Performance Engineering Plastics Revenue Share by Players/Suppliers (2012-2017)

Figure 2016 United States High Performance Engineering Plastics Revenue Share by Players/Suppliers

Figure 2017 United States High Performance Engineering Plastics Revenue Share by Players/Suppliers

Table United States Market High Performance Engineering Plastics Average Price (USD/MT) of Key Players/Suppliers (2012-2017)

Figure United States Market High Performance Engineering Plastics Average Price (USD/MT) of Key Players/Suppliers in 2016

Figure United States High Performance Engineering Plastics Market Share of Top 3 Players/Suppliers

Figure United States High Performance Engineering Plastics Market Share of Top 5 Players/Suppliers

Table United States Players/Suppliers High Performance Engineering Plastics Manufacturing Base Distribution and Sales Area

Table United States Players/Suppliers High Performance Engineering Plastics Product Category

Table United States High Performance Engineering Plastics Sales (K MT) by Region (2012-2017)

Table United States High Performance Engineering Plastics Sales Share by Region (2012-2017)

Figure United States High Performance Engineering Plastics Sales Share by Region (2012-2017)

Figure United States High Performance Engineering Plastics Sales Market Share by Region in 2016

Table United States High Performance Engineering Plastics Revenue (Million USD) and Market Share by Region (2012-2017)

Table United States High Performance Engineering Plastics Revenue Share by Region (2012-2017)

Figure United States High Performance Engineering Plastics Revenue Market Share by Region (2012-2017)

Figure United States High Performance Engineering Plastics Revenue Market Share by Region in 2016

Table United States High Performance Engineering Plastics Price (USD/MT) by Region (2012-2017)

Table United States High Performance Engineering Plastics Sales (K MT) by Type (2012-2017)

Table United States High Performance Engineering Plastics Sales Share by Type (2012-2017)

Figure United States High Performance Engineering Plastics Sales Share by Type (2012-2017)

Figure United States High Performance Engineering Plastics Sales Market Share by Type in 2016

Table United States High Performance Engineering Plastics Revenue (Million USD) and Market Share by Type (2012-2017)

Table United States High Performance Engineering Plastics Revenue Share by Type (2012-2017)

Figure Revenue Market Share of High Performance Engineering Plastics by Type (2012-2017)

Figure Revenue Market Share of High Performance Engineering Plastics by Type in 2016

Table United States High Performance Engineering Plastics Price (USD/MT) by Types (2012-2017)

Figure United States High Performance Engineering Plastics Sales Growth Rate by Type (2012-2017)

Table United States High Performance Engineering Plastics Sales (K MT) by Application (2012-2017)

Table United States High Performance Engineering Plastics Sales Market Share by Application (2012-2017)

Figure United States High Performance Engineering Plastics Sales Market Share by Application (2012-2017)

Figure United States High Performance Engineering Plastics Sales Market Share by Application in 2016

Table United States High Performance Engineering Plastics Sales Growth Rate by Application (2012-2017)

Figure United States High Performance Engineering Plastics Sales Growth Rate by Application (2012-2017)

Table BASF Basic Information List

Table BASF High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure BASF High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure BASF High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure BASF High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Asahi Kasei Basic Information List

Table Asahi Kasei High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Asahi Kasei High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Asahi Kasei High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Asahi Kasei High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table DSM Basic Information List

Table DSM High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure DSM High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure DSM High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure DSM High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Invista Basic Information List

Table Invista High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Invista High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Invista High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Invista High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Ascend Basic Information List

Table Ascend High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Ascend High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Ascend High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Ascend High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Solvay Basic Information List

Table Solvay High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Solvay High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Solvay High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Solvay High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Dupont Basic Information List

Table Dupont High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Dupont High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Dupont High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Dupont High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Radici Group Basic Information List

Table Radici Group High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Radici Group High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Radici Group High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Radici Group High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Shenma Basic Information List

Table Shenma High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Shenma High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Shenma High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Shenma High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Hua Yang Basic Information List

Table Hua Yang High Performance Engineering Plastics Sales (K MT), Revenue (Million USD), Price (USD/MT) and Gross Margin (2012-2017)

Figure Hua Yang High Performance Engineering Plastics Sales Growth Rate (2012-2017)

Figure Hua Yang High Performance Engineering Plastics Sales Market Share in United States (2012-2017)

Figure Hua Yang High Performance Engineering Plastics Revenue Market Share in United States (2012-2017)

Table Production Base and Market Concentration Rate of Raw Material

Figure Price Trend of Key Raw Materials

Table Key Suppliers of Raw Materials

Figure Manufacturing Cost Structure of High Performance Engineering Plastics

Figure Manufacturing Process Analysis of High Performance Engineering Plastics

Figure High Performance Engineering Plastics Industrial Chain Analysis

Table Raw Materials Sources of High Performance Engineering Plastics Major Players/Suppliers in 2016

Table Major Buyers of High Performance Engineering Plastics

Table Distributors/Traders List

Figure United States High Performance Engineering Plastics Sales Volume (K MT) and Growth Rate Forecast (2017-2022)

Figure United States High Performance Engineering Plastics Revenue (Million USD) and Growth Rate Forecast (2017-2022)

Figure United States High Performance Engineering Plastics Price (USD/MT) Trend Forecast (2017-2022)

Table United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Type (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Type (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Type in 2022

Table United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Application (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Application (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Application in 2022

Table United States High Performance Engineering Plastics Sales Volume (K MT) Forecast by Region (2017-2022)

Table United States High Performance Engineering Plastics Sales Volume Share Forecast by Region (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume Share Forecast by Region (2017-2022)

Figure United States High Performance Engineering Plastics Sales Volume Share Forecast by Region in 2022

Table Research Programs/Design for This Report

Figure Bottom-up and Top-down Approaches for This Report

Figure Data Triangulation

Table Key Data Information from Secondary Sources

Table Key Data Information from Primary Sources

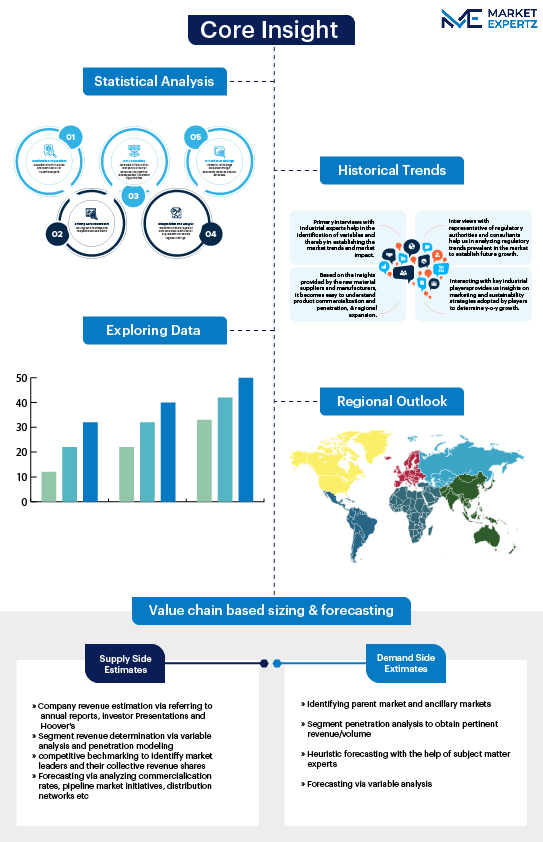

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"