Condition Monitoring Systems Market Analysis By Application (Manufacturing, Oil and Gas, Power Generation, Aerospace and Defense, Automotive, Others), By Type (Vibration Monitoring, Thermography, Oil Analysis, Noise Monitoring, Others)

- Report ID: ME_002308

- Format: Electronic (PDF)

- Publish Type: Publish

- Number of Pages: 250

Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 7.01 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The Condition Monitoring Systems Market size is estimated to grow at a CAGR of 6.78% between 2022 and 2032. The market size is forecast to increase by USD 8,543.21 million. The growth of the market depends on several factors, including the increasing need for predictive maintenance, rising demand for real-time monitoring of assets, and the growing adoption of Industrial Internet of Things (IIoT) technologies. A condition monitoring system refers to a set of hardware and software components that are used to monitor the operational condition of machinery and equipment in real-time. It helps in detecting any potential faults or abnormalities in the equipment, allowing for timely maintenance and minimizing downtime.

Condition Monitoring Systems Market Overview

Drivers

One of the key factors driving the condition monitoring systems market growth is the increasing need for predictive maintenance. Predictive maintenance involves monitoring the condition of equipment and machinery to identify potential failures before they occur. It helps in reducing unplanned downtime, optimizing maintenance schedules, and improving overall operational efficiency. Condition monitoring systems play a crucial role in enabling predictive maintenance by continuously monitoring the health of assets and providing real-time insights into their condition. This helps in identifying any early signs of deterioration or faults, allowing for proactive maintenance actions to be taken. Hence, the increasing adoption of predictive maintenance strategies is expected to drive market growth during the forecast period.

Trends

A key trend shaping the condition monitoring systems market growth is the integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies. AI and ML algorithms can analyze large volumes of data collected from sensors and other monitoring devices to identify patterns, anomalies, and potential failures. By leveraging AI and ML, condition monitoring systems can provide more accurate and reliable insights into the condition of assets, enabling predictive maintenance and reducing the risk of unexpected failures. Additionally, the integration of AI and ML technologies allows for the automation of maintenance processes, improving operational efficiency and reducing costs. Hence, the increasing adoption of AI and ML in condition monitoring systems is expected to drive market growth during the forecast period.

Restraints:

One of the key challenges hindering the condition monitoring systems market growth is the high implementation and maintenance costs. Condition monitoring systems require the installation of sensors, data acquisition devices, and software platforms, which can be expensive. Additionally, the integration of these systems with existing machinery and equipment may require modifications or upgrades, further adding to the costs. Moreover, the maintenance and calibration of condition monitoring systems also require additional investments. These high costs can be a barrier to the adoption of condition monitoring systems, especially for small and medium-sized enterprises with limited budgets. Hence, the high implementation and maintenance costs are expected to hinder market growth during the forecast period.

Condition Monitoring Systems Market Segmentation By Application

The manufacturing segment is estimated to witness significant growth during the forecast period. Condition monitoring systems play a crucial role in the manufacturing industry by ensuring the continuous and reliable operation of critical machinery and equipment. By monitoring the condition of assets such as motors, pumps, compressors, and bearings, condition monitoring systems help in detecting any potential faults or abnormalities that could lead to unplanned downtime or production disruptions. This allows for timely maintenance actions to be taken, minimizing the risk of equipment failures and optimizing overall operational efficiency. Hence, the increasing adoption of condition monitoring systems in the manufacturing sector is expected to drive the growth of this segment, which in turn will drive the market growth during the forecast period.

Condition Monitoring Systems Market Segmentation By Type

The vibration monitoring segment is expected to witness significant growth during the forecast period. Vibration monitoring is one of the most widely used techniques in condition monitoring systems. It involves the measurement and analysis of vibrations in machinery and equipment to detect any potential faults or abnormalities. Vibration sensors are installed on the equipment, and the data collected is analyzed to identify any changes in vibration patterns that could indicate a problem. Vibration monitoring helps in detecting faults such as misalignment, unbalance, bearing wear, and mechanical looseness, allowing for timely maintenance actions to be taken. Hence, the increasing adoption of vibration monitoring techniques is expected to fuel the demand for this segment, which in turn will drive the market growth during the forecast period.

Download the report summary now!

Request pdf SampleNorth America is estimated to contribute 35% to the growth of the global market during the forecast period. The region has a strong presence of key market players and is witnessing increasing investments in condition monitoring systems. The manufacturing sector in North America is adopting advanced technologies such as IIoT and predictive maintenance to improve operational efficiency and reduce downtime. Additionally, the region has stringent regulations and standards related to equipment safety and reliability, which are driving the adoption of condition monitoring systems. Moreover, the increasing focus on energy efficiency and sustainability in industries such as oil and gas, power generation, and automotive is further fueling the demand for condition monitoring systems. Hence, the presence of key market players, adoption of advanced technologies, and regulatory requirements are expected to drive market growth in North America during the forecast period.

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

- ABB Ltd.

- Emerson Electric Co.

- General Electric Co.

- Honeywell International Inc.

- National Instruments Corp.

- Parker Hannifin Corp.

- Rockwell Automation Inc.

- Schneider Electric SE

- SKF AB

- Siemens AG

- SKF AB

- Fluke Corporation

- Brüel & Kjær Vibro GmbH

- PCB Piezotronics Inc.

- PRÜFTECHNIK Dieter Busch AG

- Analog Devices Inc.

- Commtest Instruments Ltd.

- Flir Systems Inc.

- IFM Electronic GmbH

- NTS Group

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Segment Overview

The condition monitoring systems market report forecasts market growth by revenue at global, regional & country levels and provides an analysis of the latest trends and growth opportunities from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032)

o Manufacturing

o Oil and Gas

o Power Generation

o Aerospace and Defense

o Automotive

o Others

- Type Outlook (USD Million, 2019 - 2032)

o Vibration Monitoring

o Thermography

o Oil Analysis

o Noise Monitoring

o Others

- Geography Outlook (USD Million, 2019 - 2032)

o North America

The U.S.

Canada

o Europe

U.K.

Germany

France

Rest of Europe

o APAC

China

India

o South America

Chile

Argentina

Brazil

o Middle East & Africa

Saudi Arabia

South Africa

Rest of the Middle East & Africa

Table of Contents

Global Machine Condition Monitoring Systems Market Professional Survey Report 2017

1 Industry Overview of Machine Condition Monitoring Systems

1.1 Definition and Specifications of Machine Condition Monitoring Systems

1.1.1 Definition of Machine Condition Monitoring Systems

1.1.2 Specifications of Machine Condition Monitoring Systems

1.2 Classification of Machine Condition Monitoring Systems

1.2.1 Online Machine Monitoring

1.2.2 Portable Machine Monitoring

1.2.3 Others

1.3 Applications of Machine Condition Monitoring Systems

1.3.1 Energy & Power

1.3.2 Automotive

1.3.3 Aerospace & Defense

1.3.4 Chemical

1.3.5 Others

1.4 Market Segment by Regions

1.4.1 North America

1.4.2 China

1.4.3 Europe

1.4.4 Southeast Asia

1.4.5 Japan

1.4.6 India

2 Manufacturing Cost Structure Analysis of Machine Condition Monitoring Systems

2.1 Raw Material and Suppliers

2.2 Manufacturing Cost Structure Analysis of Machine Condition Monitoring Systems

2.3 Manufacturing Process Analysis of Machine Condition Monitoring Systems

2.4 Industry Chain Structure of Machine Condition Monitoring Systems

3 Technical Data and Manufacturing Plants Analysis of Machine Condition Monitoring Systems

3.1 Capacity and Commercial Production Date of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

3.2 Manufacturing Plants Distribution of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

3.3 R&D Status and Technology Source of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

3.4 Raw Materials Sources Analysis of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

4 Global Machine Condition Monitoring Systems Overall Market Overview

4.1 2012-2017E Overall Market Analysis

4.2 Capacity Analysis

4.2.1 2012-2017E Global Machine Condition Monitoring Systems Capacity and Growth Rate Analysis

4.2.2 2016 Machine Condition Monitoring Systems Capacity Analysis (Company Segment)

4.3 Sales Analysis

4.3.1 2012-2017E Global Machine Condition Monitoring Systems Sales and Growth Rate Analysis

4.3.2 2016 Machine Condition Monitoring Systems Sales Analysis (Company Segment)

4.4 Sales Price Analysis

4.4.1 2012-2017E Global Machine Condition Monitoring Systems Sales Price

4.4.2 2016 Machine Condition Monitoring Systems Sales Price Analysis (Company Segment)

5 Machine Condition Monitoring Systems Regional Market Analysis

5.1 North America Machine Condition Monitoring Systems Market Analysis

5.1.1 North America Machine Condition Monitoring Systems Market Overview

5.1.2 North America 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.1.3 North America 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.1.4 North America 2016 Machine Condition Monitoring Systems Market Share Analysis

5.2 China Machine Condition Monitoring Systems Market Analysis

5.2.1 China Machine Condition Monitoring Systems Market Overview

5.2.2 China 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.2.3 China 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.2.4 China 2016 Machine Condition Monitoring Systems Market Share Analysis

5.3 Europe Machine Condition Monitoring Systems Market Analysis

5.3.1 Europe Machine Condition Monitoring Systems Market Overview

5.3.2 Europe 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.3.3 Europe 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.3.4 Europe 2016 Machine Condition Monitoring Systems Market Share Analysis

5.4 Southeast Asia Machine Condition Monitoring Systems Market Analysis

5.4.1 Southeast Asia Machine Condition Monitoring Systems Market Overview

5.4.2 Southeast Asia 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.4.3 Southeast Asia 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.4.4 Southeast Asia 2016 Machine Condition Monitoring Systems Market Share Analysis

5.5 Japan Machine Condition Monitoring Systems Market Analysis

5.5.1 Japan Machine Condition Monitoring Systems Market Overview

5.5.2 Japan 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.5.3 Japan 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.5.4 Japan 2016 Machine Condition Monitoring Systems Market Share Analysis

5.6 India Machine Condition Monitoring Systems Market Analysis

5.6.1 India Machine Condition Monitoring Systems Market Overview

5.6.2 India 2012-2017E Machine Condition Monitoring Systems Local Supply, Import, Export, Local Consumption Analysis

5.6.3 India 2012-2017E Machine Condition Monitoring Systems Sales Price Analysis

5.6.4 India 2016 Machine Condition Monitoring Systems Market Share Analysis

6 Global 2012-2017E Machine Condition Monitoring Systems Segment Market Analysis (by Type)

6.1 Global 2012-2017E Machine Condition Monitoring Systems Sales by Type

6.2 Different Types of Machine Condition Monitoring Systems Product Interview Price Analysis

6.3 Different Types of Machine Condition Monitoring Systems Product Driving Factors Analysis

6.3.1 Online Machine Monitoring of Machine Condition Monitoring Systems Growth Driving Factor Analysis

6.3.2 Portable Machine Monitoring of Machine Condition Monitoring Systems Growth Driving Factor Analysis

6.3.3 Others of Machine Condition Monitoring Systems Growth Driving Factor Analysis

7 Global 2012-2017E Machine Condition Monitoring Systems Segment Market Analysis (by Application)

7.1 Global 2012-2017E Machine Condition Monitoring Systems Consumption by Application

7.2 Different Application of Machine Condition Monitoring Systems Product Interview Price Analysis

7.3 Different Application of Machine Condition Monitoring Systems Product Driving Factors Analysis

7.3.1 Energy & Power of Machine Condition Monitoring Systems Growth Driving Factor Analysis

7.3.2 Automotive of Machine Condition Monitoring Systems Growth Driving Factor Analysis

7.3.3 Aerospace & Defense of Machine Condition Monitoring Systems Growth Driving Factor Analysis

7.3.4 Chemical of Machine Condition Monitoring Systems Growth Driving Factor Analysis

7.3.5 Others of Machine Condition Monitoring Systems Growth Driving Factor Analysis

8 Major Manufacturers Analysis of Machine Condition Monitoring Systems

8.1 Emerson Electric Co.

8.1.1 Company Profile

8.1.2 Product Picture and Specifications

8.1.2.1 Product A

8.1.2.2 Product B

8.1.3 Emerson Electric Co. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.1.4 Emerson Electric Co. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.2 General Electric

8.2.1 Company Profile

8.2.2 Product Picture and Specifications

8.2.2.1 Product A

8.2.2.2 Product B

8.2.3 General Electric 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.2.4 General Electric 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.3 Honeywell International Inc.

8.3.1 Company Profile

8.3.2 Product Picture and Specifications

8.3.2.1 Product A

8.3.2.2 Product B

8.3.3 Honeywell International Inc. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.3.4 Honeywell International Inc. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.4 National Instruments Corp.

8.4.1 Company Profile

8.4.2 Product Picture and Specifications

8.4.2.1 Product A

8.4.2.2 Product B

8.4.3 National Instruments Corp. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.4.4 National Instruments Corp. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.5 SKF AB

8.5.1 Company Profile

8.5.2 Product Picture and Specifications

8.5.2.1 Product A

8.5.2.2 Product B

8.5.3 SKF AB 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.5.4 SKF AB 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.6 ALS Ltd.

8.6.1 Company Profile

8.6.2 Product Picture and Specifications

8.6.2.1 Product A

8.6.2.2 Product B

8.6.3 ALS Ltd. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.6.4 ALS Ltd. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.7 Meggitt PLC

8.7.1 Company Profile

8.7.2 Product Picture and Specifications

8.7.2.1 Product A

8.7.2.2 Product B

8.7.3 Meggitt PLC 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.7.4 Meggitt PLC 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.8 Parker Hannifin Corp.

8.8.1 Company Profile

8.8.2 Product Picture and Specifications

8.8.2.1 Product A

8.8.2.2 Product B

8.8.3 Parker Hannifin Corp. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.8.4 Parker Hannifin Corp. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.9 Rockwell Automation, Inc.

8.9.1 Company Profile

8.9.2 Product Picture and Specifications

8.9.2.1 Product A

8.9.2.2 Product B

8.9.3 Rockwell Automation, Inc. 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.9.4 Rockwell Automation, Inc. 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.10 Schaeffler AG

8.10.1 Company Profile

8.10.2 Product Picture and Specifications

8.10.2.1 Product A

8.10.2.2 Product B

8.10.3 Schaeffler AG 2016 Machine Condition Monitoring Systems Sales, Ex-factory Price, Revenue, Gross Margin Analysis

8.10.4 Schaeffler AG 2016 Machine Condition Monitoring Systems Business Region Distribution Analysis

8.11 Azima DLI Corp.

8.12 Bruel & Kjaer Vibro GmbH

9 Development Trend of Analysis of Machine Condition Monitoring Systems Market

9.1 Global Machine Condition Monitoring Systems Market Trend Analysis

9.1.1 Global 2017-2022 Machine Condition Monitoring Systems Market Size (Volume and Value) Forecast

9.1.2 Global 2017-2022 Machine Condition Monitoring Systems Sales Price Forecast

9.2 Machine Condition Monitoring Systems Regional Market Trend

9.2.1 North America 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.2.2 China 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.2.3 Europe 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.2.4 Southeast Asia 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.2.5 Japan 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.2.6 India 2017-2022 Machine Condition Monitoring Systems Consumption Forecast

9.3 Machine Condition Monitoring Systems Market Trend (Product Type)

9.4 Machine Condition Monitoring Systems Market Trend (Application)

10 Machine Condition Monitoring Systems Marketing Type Analysis

10.1 Machine Condition Monitoring Systems Regional Marketing Type Analysis

10.2 Machine Condition Monitoring Systems International Trade Type Analysis

10.3 Traders or Distributors with Contact Information of Machine Condition Monitoring Systems by Region

10.4 Machine Condition Monitoring Systems Supply Chain Analysis

11 Consumers Analysis of Machine Condition Monitoring Systems

11.1 Consumer 1 Analysis

11.2 Consumer 2 Analysis

11.3 Consumer 3 Analysis

11.4 Consumer 4 Analysis

12 Conclusion of the Global Machine Condition Monitoring Systems Market Professional Survey Report 2017

Methodology

Analyst Introduction

Data Source

List of Tables and Figures

Figure Picture of Machine Condition Monitoring Systems

Table Product Specifications of Machine Condition Monitoring Systems

Table Classification of Machine Condition Monitoring Systems

Figure Global Production Market Share of Machine Condition Monitoring Systems by Type in 2016

Figure Online Machine Monitoring Picture

Table Major Manufacturers of Online Machine Monitoring

Figure Portable Machine Monitoring Picture

Table Major Manufacturers of Portable Machine Monitoring

Figure Others Picture

Table Major Manufacturers of Others

Table Applications of Machine Condition Monitoring Systems

Figure Global Consumption Volume Market Share of Machine Condition Monitoring Systems by Application in 2016

Figure Energy & Power Examples

Table Major Consumers in Energy & Power

Figure Automotive Examples

Table Major Consumers in Automotive

Figure Aerospace & Defense Examples

Table Major Consumers in Aerospace & Defense

Figure Chemical Examples

Table Major Consumers in Chemical

Figure Others Examples

Table Major Consumers in Others

Figure Market Share of Machine Condition Monitoring Systems by Regions

Figure North America Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Figure China Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Figure Europe Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Figure Southeast Asia Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Figure Japan Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Figure India Machine Condition Monitoring Systems Market Size (Million USD) (2012-2022)

Table Machine Condition Monitoring Systems Raw Material and Suppliers

Table Manufacturing Cost Structure Analysis of Machine Condition Monitoring Systems in 2016

Figure Manufacturing Process Analysis of Machine Condition Monitoring Systems

Figure Industry Chain Structure of Machine Condition Monitoring Systems

Table Capacity and Commercial Production Date of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

Table Manufacturing Plants Distribution of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

Table R&D Status and Technology Source of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

Table Raw Materials Sources Analysis of Global Machine Condition Monitoring Systems Major Manufacturers in 2016

Table Global Capacity, Sales , Price, Cost, Sales Revenue (M USD) and Gross Margin of Machine Condition Monitoring Systems 2012-2017

Figure Global 2012-2017E Machine Condition Monitoring Systems Market Size (Volume) and Growth Rate

Figure Global 2012-2017E Machine Condition Monitoring Systems Market Size (Value) and Growth Rate

Table 2012-2017E Global Machine Condition Monitoring Systems Capacity and Growth Rate

Table 2016 Global Machine Condition Monitoring Systems Capacity (K Units) List (Company Segment)

Table 2012-2017E Global Machine Condition Monitoring Systems Sales (K Units) and Growth Rate

Table 2016 Global Machine Condition Monitoring Systems Sales (K Units) List (Company Segment)

Table 2012-2017E Global Machine Condition Monitoring Systems Sales Price (USD/Unit)

Table 2016 Global Machine Condition Monitoring Systems Sales Price (USD/Unit) List (Company Segment)

Figure North America Capacity Overview

Table North America Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure North America 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure North America 2016 Machine Condition Monitoring Systems Sales Market Share

Figure China Capacity Overview

Table China Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure China 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure China 2016 Machine Condition Monitoring Systems Sales Market Share

Figure Europe Capacity Overview

Table Europe Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure Europe 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure Europe 2016 Machine Condition Monitoring Systems Sales Market Share

Figure Southeast Asia Capacity Overview

Table Southeast Asia Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure Southeast Asia 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure Southeast Asia 2016 Machine Condition Monitoring Systems Sales Market Share

Figure Japan Capacity Overview

Table Japan Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure Japan 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure Japan 2016 Machine Condition Monitoring Systems Sales Market Share

Figure India Capacity Overview

Table India Supply, Import, Export and Consumption (K Units) of Machine Condition Monitoring Systems 2012-2017E

Figure India 2012-2017E Machine Condition Monitoring Systems Sales Price (USD/Unit)

Figure India 2016 Machine Condition Monitoring Systems Sales Market Share

Table Global 2012-2017E Machine Condition Monitoring Systems Sales (K Units) by Type

Table Different Types Machine Condition Monitoring Systems Product Interview Price

Table Global 2012-2017E Machine Condition Monitoring Systems Sales (K Units) by Application

Table Different Application Machine Condition Monitoring Systems Product Interview Price

Table Emerson Electric Co. Information List

Table Product A Overview

Table Product B Overview

Table 2016 Emerson Electric Co. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Emerson Electric Co. Machine Condition Monitoring Systems Business Region Distribution

Table General Electric Information List

Table Product A Overview

Table Product B Overview

Table 2016 General Electric Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 General Electric Machine Condition Monitoring Systems Business Region Distribution

Table Honeywell International Inc. Information List

Table Product A Overview

Table Product B Overview

Table 2015 Honeywell International Inc. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Honeywell International Inc. Machine Condition Monitoring Systems Business Region Distribution

Table National Instruments Corp. Information List

Table Product A Overview

Table Product B Overview

Table 2016 National Instruments Corp. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 National Instruments Corp. Machine Condition Monitoring Systems Business Region Distribution

Table SKF AB Information List

Table Product A Overview

Table Product B Overview

Table 2016 SKF AB Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 SKF AB Machine Condition Monitoring Systems Business Region Distribution

Table ALS Ltd. Information List

Table Product A Overview

Table Product B Overview

Table 2016 ALS Ltd. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 ALS Ltd. Machine Condition Monitoring Systems Business Region Distribution

Table Meggitt PLC Information List

Table Product A Overview

Table Product B Overview

Table 2016 Meggitt PLC Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Meggitt PLC Machine Condition Monitoring Systems Business Region Distribution

Table Parker Hannifin Corp. Information List

Table Product A Overview

Table Product B Overview

Table 2016 Parker Hannifin Corp. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Parker Hannifin Corp. Machine Condition Monitoring Systems Business Region Distribution

Table Rockwell Automation, Inc. Information List

Table Product A Overview

Table Product B Overview

Table 2016 Rockwell Automation, Inc. Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Rockwell Automation, Inc. Machine Condition Monitoring Systems Business Region Distribution

Table Schaeffler AG Information List

Table Product A Overview

Table Product B Overview

Table 2016 Schaeffler AG Machine Condition Monitoring Systems Revenue (Million USD), Sales (K Units), Ex-factory Price (USD/Unit)

Figure 2016 Schaeffler AG Machine Condition Monitoring Systems Business Region Distribution

Table Azima DLI Corp. Information List

Table Bruel & Kjaer Vibro GmbH Information List

Figure Global 2017-2022 Machine Condition Monitoring Systems Market Size (K Units) and Growth Rate Forecast

Figure Global 2017-2022 Machine Condition Monitoring Systems Market Size (Million USD) and Growth Rate Forecast

Figure Global 2017-2022 Machine Condition Monitoring Systems Sales Price (USD/Unit) Forecast

Figure North America 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Figure China 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Figure Europe 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Figure Southeast Asia 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Figure Japan 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Figure India 2017-2022 Machine Condition Monitoring Systems Consumption Volume (K Units) and Growth Rate Forecast

Table Global Sales Volume (K Units) of Machine Condition Monitoring Systems by Type 2017-2022

Table Global Consumption Volume (K Units) of Machine Condition Monitoring Systems by Application 2017-2022

Table Traders or Distributors with Contact Information of Machine Condition Monitoring Systems by Region

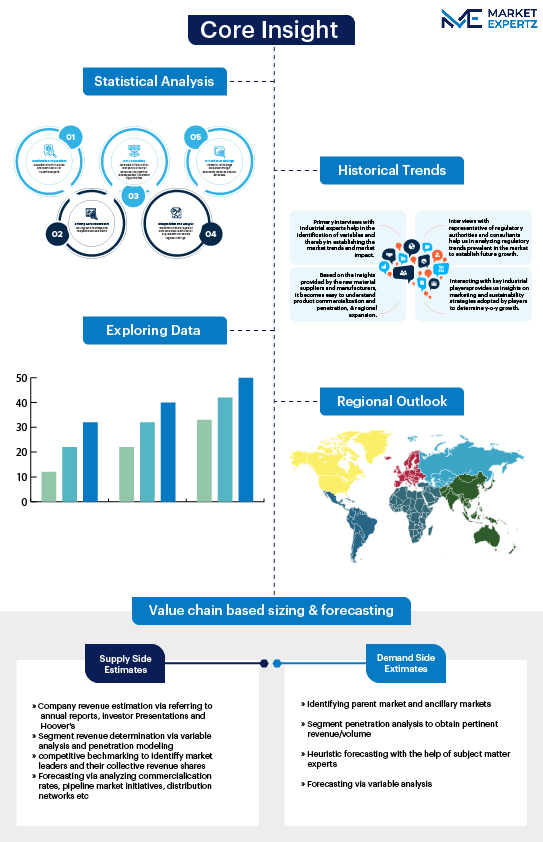

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"