Metal Injection Molding Parts (MIM Parts) Market Analysis By Application (Aerospace and Defense, Medical and Healthcare, Automotive, Electronics, Consumer Goods, Others), By Material Type (Stainless Steel, Titanium Alloys, Nickel-Based Alloys, Ferrous Alloys, Others), and By Region Forecast to 2032

- Report ID: ME_00109711

- Format: Electronic (PDF)

- Publish Type: Publish

- Number of Pages: 250

Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 8.33 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

The Metal Injection Molding Parts (MIM Parts) Market size is projected to witness substantial growth, with an estimated CAGR of 6.75% from 2022 to 2032. This growth is expected to result in an increase in market size by USD 3,562.89 million. Several factors are poised to drive the market, including the expanding demand for precision-engineered metal components across various industries, the rise of advanced manufacturing techniques, and the increasing need for complex and intricate metal parts in automotive, aerospace, and medical applications.

Metal Injection Molding Parts (MIM Parts) Market Overview:

Drivers:

One of the primary drivers fueling the growth of the Metal Injection Molding Parts (MIM Parts) Market is the escalating demand for precision and intricate metal components. MIM technology offers a cost-effective and efficient means of producing small, complex, and high-precision metal parts, catering to the evolving needs of industries such as automotive, aerospace, medical, and consumer electronics. This demand for finely detailed components, often with intricate geometries, is expected to bolster the adoption of MIM technology, thereby driving market growth.

Furthermore, advancements in manufacturing techniques, including the development of high-performance feedstock materials and improved MIM processes, are enhancing the feasibility and reliability of MIM parts production. This continuous improvement in MIM technology is anticipated to propel the market forward during the forecast period.

Trends:

A prominent trend shaping the Metal Injection Molding Parts (MIM Parts) Market is the increasing integration of MIM components in the automotive industry. The automotive sector is incorporating MIM parts for applications such as fuel injection systems, transmission components, and interior components due to their ability to meet stringent performance and weight reduction requirements. This trend is expected to gain momentum as automakers seek lightweight and durable solutions to enhance fuel efficiency and overall vehicle performance.

Additionally, the medical industry is witnessing a surge in the adoption of MIM parts for manufacturing intricate surgical instruments and orthopedic implants. The biocompatible nature of MIM materials, combined with their ability to produce highly complex shapes, positions MIM as a preferred choice for medical applications, thereby contributing to market growth.

Restraints:

One of the key challenges hindering the Metal Injection Molding Parts (MIM Parts) Market growth is the cost associated with tooling and equipment. Setting up and maintaining MIM production facilities requires significant capital investment, particularly for the development of molds and specialized equipment. This initial cost can act as a barrier to entry for smaller manufacturers and limit market expansion.

Moreover, the MIM process involves a complex sequence of steps, including mixing metal powder with a binder, injection molding, debinding, and sintering. Each of these steps requires precise control and expertise, leading to potential production challenges and quality issues. Overcoming these challenges and maintaining consistency in the manufacturing process can be a restraint for market growth.

Metal Injection Molding Parts (MIM Parts) Market Segmentation by Application:

The automotive and aerospace segments are expected to witness substantial growth within the Metal Injection Molding Parts (MIM Parts) Market during the forecast period.

Automotive: Metal Injection Molding is gaining traction in the automotive industry for producing components like fuel injectors, transmission parts, and engine components. The demand for lightweight materials and intricate designs in the automotive sector is expected to drive the adoption of MIM parts.

Aerospace: The aerospace industry is increasingly turning to MIM technology for manufacturing complex, high-performance components used in aircraft and spacecraft. MIM parts offer a combination of precision, durability, and weight savings, making them suitable for aerospace applications.

Medical: MIM parts are also making inroads in the medical sector, particularly for producing surgical instruments and orthopedic implants. The ability to create intricate and biocompatible components makes MIM an attractive choice for medical device manufacturers.

Consumer Electronics: MIM parts find applications in consumer electronics, such as mobile phones and wearable devices, where small, intricate, and high-precision components are required.

Metal Injection Molding Parts (MIM Parts) Market Segmentation by Type:

Stainless Steel MIM Parts: Stainless steel MIM parts are widely used due to their corrosion resistance and durability, making them suitable for applications in various industries.

Titanium MIM Parts: Titanium MIM parts are gaining popularity in aerospace and medical applications due to their lightweight properties and biocompatibility.

Ferrous MIM Parts: Ferrous MIM parts encompass a range of materials, including iron and iron-based alloys, and are utilized in automotive, consumer electronics, and industrial applications.

Non-Ferrous MIM Parts: Non-ferrous MIM parts consist of materials like copper and aluminum and find applications in electrical components and heat sinks.

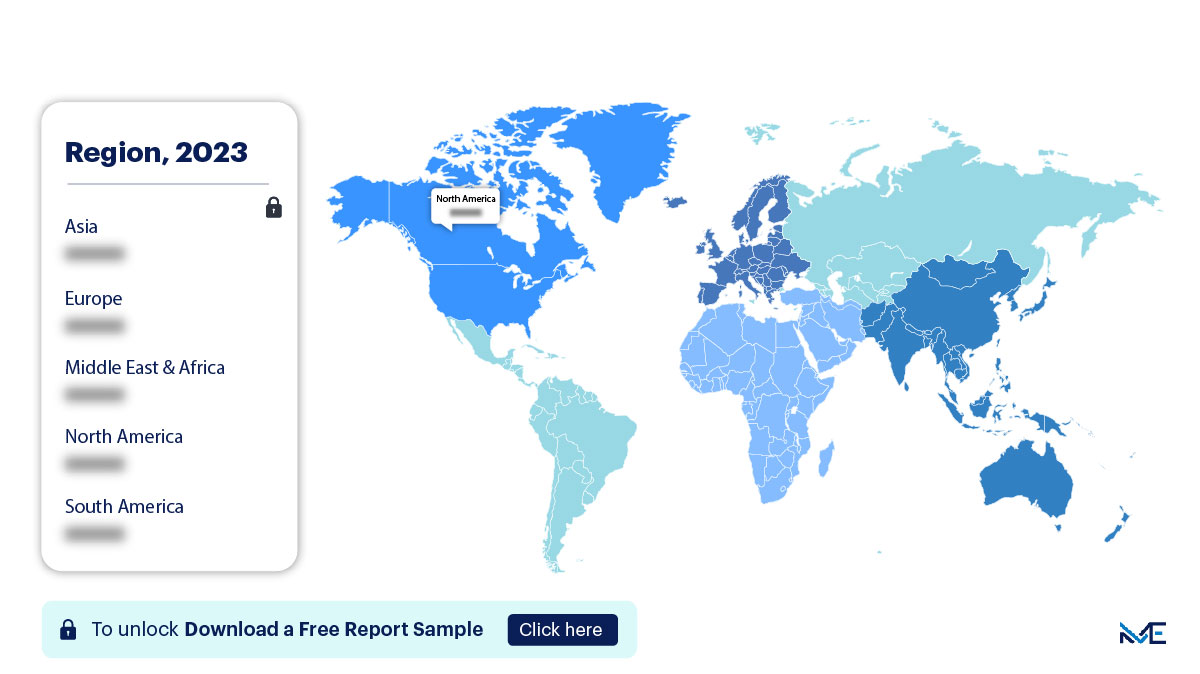

Regional Overview:

Download the report summary now!

Request pdf Sample

North America: North America is expected to play a significant role in the Metal Injection Molding Parts (MIM Parts) Market, driven by the presence of key players and the growing demand for MIM components in aerospace and medical applications.

Europe: Europe is likely to witness steady growth in the MIM market, with applications in automotive and industrial sectors driving demand.

Asia-Pacific: Asia-Pacific is poised to be a prominent market for MIM parts, driven by the burgeoning automotive industry, especially in countries like China and India, and the growing medical device manufacturing sector.

South America: South America is expected to witness moderate growth in the MIM market, primarily in the automotive and consumer electronics sectors.

Middle East & Africa: The Middle East & Africa region may experience gradual adoption of MIM technology, driven by industrial and aerospace applications.

Metal Injection Molding Parts (MIM Parts) Market Customer Landscape:

The Metal Injection Molding Parts (MIM Parts) Market analysis encompasses the entire customer lifecycle, from early adopters to late-stage customers. It evaluates adoption rates across different regions based on market penetration. Additionally, the report delves into key purchase criteria and factors influencing price sensitivity to aid companies in devising growth strategies.

Who are the Major Metal Injection Molding Parts (MIM Parts) Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

The research report also includes detailed analyses of the competitive landscape of the market and information about 11 market companies

- MetalTech Inc.

- Precision MIM Solutions

- TechAlloy MIM Corporation

- MIMTech Group

- Advanced MIM Products

- GlobalMIM Parts

- Superior MIM Components

- EcoMIM Technologies

- NanoMIM Corporation

- MIM Innovations Ltd.

- TechMIM Solutions

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Segment Overview

The metal injection molding parts (MIM Parts) market report forecasts market growth by revenue at global, regional & country levels and provides an analysis of the latest trends and growth opportunities from 2019 to 2032.

- Application Outlook (USD Million, 2019 - 2032)

- Aerospace and Defense

- Medical and Healthcare

- Automotive

- Electronics

- Consumer Goods

- Others

- Material Type Outlook (USD Million, 2019 - 2032)

- Stainless Steel

- Titanium Alloys

- Nickel-Based Alloys

- Ferrous Alloys

- Others

- Geography Outlook (USD Million, 2019 - 2032)

- North America

- The U.S.

- Canada

- Europe

- K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- Japan

- South America

- Brazil

- Argentina

- Chile

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Table of Content

Chapter 1 About the Metal Injection Molding Parts (MIM Parts) Industry

1.1 Industry Definition and Types

1.1.1 Stainless Steel

1.1.2 Steel

1.1.3 Alloy Steel

1.2 Main Market Activities

1.3 Similar Industries

1.4 Industry at a Glance

Chapter 2 World Market Competition Landscape

2.1 Metal Injection Molding Parts (MIM Parts) Markets by Regions

2.1.1 USA

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.1.2 Europe

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.1.3 China

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.1.4 India

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.1.5 Japan

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.1.6 South East Asia

Market Revenue (M USD) and Growth Rate 2015-2020

Sales and Growth Rate 2015-2020

Major Players

2.2 World Metal Injection Molding Parts (MIM Parts) Market by Types

Stainless Steel

Steel

Alloy Steel

2.3 World Metal Injection Molding Parts (MIM Parts) Market by Applications

Medical

Industrial

Automotive

Electronics

Firearms

2.4 World Metal Injection Molding Parts (MIM Parts) Market Analysis

2.4.1 World Metal Injection Molding Parts (MIM Parts) Market Revenue and Growth Rate 2015-2020

2.4.2 World Metal Injection Molding Parts (MIM Parts) Market Consumption and Growth rate 2015-2020

2.4.3 World Metal Injection Molding Parts (MIM Parts) Market Price Analysis 2015-2020

Chapter 3 World Metal Injection Molding Parts (MIM Parts) Market share

3.1 Major Production Market share by Players

3.2 Major Revenue (M USD) Market share by Players

3.3 Major Production Market share by Regions in 2020, Through 2025

3.4 Major Revenue (M USD) Market share By Regions in 2020, Through 2025

Chapter 4 Supply Chain Analysis

4.1 Industry Supply chain Analysis

4.2 Raw material Market Analysis

4.2.1 Raw material Prices Analysis 2015-2020

4.2.2 Raw material Supply Market Analysis

4.2 Manufacturing Equipment Suppliers Analysis

4.3 Production Process Analysis

4.4 Production Cost Structure Benchmarks

4.5 End users Market Analysis

Chapter 5 Company Profiles

5.1 Indo-MIM

5.1.1 Company Details (Foundation Year, Employee Strength and etc)

5.1.2 Product Information (Picture, Specifications and Applications)

5.1.3 Revenue (M USD), Price and Operating Profits

5.2 ARC Group

5.2.1 Company Details (Foundation Year, Employee Strength and etc)

5.2.2 Product Information (Picture, Specifications and Applications)

5.2.3 Revenue (M USD), Price and Operating Profits

5.3 Schunk

5.3.1 Company Details (Foundation Year, Employee Strength and etc)

5.3.2 Product Information (Picture, Specifications and Applications)

5.3.3 Revenue (M USD), Price and Operating Profits

5.4 Sintex

5.4.1 Company Details (Foundation Year, Employee Strength and etc)

5.4.2 Product Information (Picture, Specifications and Applications)

5.4.3 Revenue (M USD), Price and Operating Profits

5.5 Praxis Powder Technology

5.5.1 Company Details (Foundation Year, Employee Strength and etc)

5.5.2 Product Information (Picture, Specifications and Applications)

5.5.3 Revenue (M USD), Price and Operating Profits

5.6 ASH? Industries

5.6.1 Company Details (Foundation Year, Employee Strength and etc)

5.6.2 Product Information (Picture, Specifications and Applications)

5.6.3 Revenue (M USD), Price and Operating Profits

5.7 Form Technologies Company

5.7.1 Company Details (Foundation Year, Employee Strength and etc)

5.7.2 Product Information (Picture, Specifications and Applications)

5.7.3 Revenue (M USD), Price and Operating Profits

5.8 Smith Metal Products

5.8.1 Company Details (Foundation Year, Employee Strength and etc)

5.8.2 Product Information (Picture, Specifications and Applications)

5.8.3 Revenue (M USD), Price and Operating Profits

5.9 NetShape Technology

5.9.1 Company Details (Foundation Year, Employee Strength and etc)

5.9.2 Product Information (Picture, Specifications and Applications)

5.9.3 Revenue (M USD), Price and Operating Profits

5.10 NIPPON PISTON RING

5.10.1 Company Details (Foundation Year, Employee Strength and etc)

5.10.2 Product Information (Picture, Specifications and Applications)

5.10.3 Revenue (M USD), Price and Operating Profits

5.11 AMT

5.11.1 Company Details (Foundation Year, Employee Strength and etc)

5.11.2 Product Information (Picture, Specifications and Applications)

5.11.3 Revenue (M USD), Price and Operating Profits

5.12 Dou Yee Technologies

5.12.1 Company Details (Foundation Year, Employee Strength and etc)

5.12.2 Product Information (Picture, Specifications and Applications)

5.12.3 Revenue (M USD), Price and Operating Profits

5.13 Shin Zu Shing

5.13.1 Company Details (Foundation Year, Employee Strength and etc)

5.13.2 Product Information (Picture, Specifications and Applications)

5.13.3 Revenue (M USD), Price and Operating Profits

5.14 GIAN

5.14.1 Company Details (Foundation Year, Employee Strength and etc)

5.14.2 Product Information (Picture, Specifications and Applications)

5.14.3 Revenue (M USD), Price and Operating Profits

5.15 Future High-tech

5.15.1 Company Details (Foundation Year, Employee Strength and etc)

5.15.2 Product Information (Picture, Specifications and Applications)

5.15.3 Revenue (M USD), Price and Operating Profits

Chapter 6 Globalisation & Trade

6.1 Business Locations

6.2 Supply channels

6.3 Marketing strategy

6.4 Barriers to Entry

Chapter 7 Distributors and Customers

7.1 Major Distributors and contact information by Regions

7.2 Major Customers and contact information by Regions

Chapter 8 Import, Export, Consumption and Consumption Value by Major Countries

8.1 USA

8.2 Germany

8.3 China

8.4 Japan

8.5 India

Chapter 9 World Metal Injection Molding Parts (MIM Parts) Market Forecast through 2025

9.1 World Metal Injection Molding Parts (MIM Parts) Demand by Regions Forecast through 2025

9.2 World Metal Injection Molding Parts (MIM Parts) Price(by Regions, Types, Applications)Analysis Forecast through 2025

9.3 World Metal Injection Molding Parts (MIM Parts) Revenue (M USD)(by Regions, Types, Applications) Forecast through 2025

9.4 World Metal Injection Molding Parts (MIM Parts) Market Analysis

9.4.1 World Metal Injection Molding Parts (MIM Parts) Market Revenue and Growth Rate 2015-2020

9.4.2 World Metal Injection Molding Parts (MIM Parts) Market Consumption and Growth rate 2015-2020

9.4.3 World Metal Injection Molding Parts (MIM Parts) Market Price Analysis 2015-2020

Chapter 10 Key success factors and Market Overview

Tables and figures

Table Main Market Activities by Regions

Table Market Revenue (M USD) and Growth Rate 2015-2020

Table Major Players

Table Market Revenue (M USD) and Growth Rate 2015-2020

Table Major Players

Table Market Revenue (M USD) and Growth Rate 2015-2020

Table Major Players

Table Market Revenue (M USD) and Growth Rate 2015-2020

Table Major Players

Table Market Revenue (M USD) and Growth Rate 2015-2020

Table Major Players

Table Major Production Market share by Players 2019

Table Major Revenue (M USD) Market share by Players 2019

Table Production Market share by Major Regions in 2015-2020

Table Production Market share by Major Regions in 2020-2025

Table Revenue (M USD) Market share by Regions in 2015-2020

Table Revenue (M USD) Market share by Regions in 2020-2025

Table Industry Supply chain Analysis

Table Raw material Prices Analysis 2015-2020

Table Raw material Suppliers Market Analysis

Table Manufacturing Equipment Suppliers Analysis

Figure Production Process Analysis

Figure Production Cost Structure

Table major End Users by Regions

Table Indo-MIM Information List

Figure Metal Injection Molding Parts (MIM Parts)Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Indo-MIM

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Indo-MIM 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Indo-MIM 2019-2020

Table ARC Group Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of ARC Group

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of ARC Group 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of ARC Group 2019-2020

Table Schunk Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Schunk

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Schunk 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Schunk 2019-2020

Table Sintex Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Sintex

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Sintex 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Sintex 2019-2020

Table Praxis Powder Technology Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Praxis Powder Technology

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Praxis Powder Technology 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Praxis Powder Technology 2019-2020

Table ASH? Industries Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of ASH? Industries

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of ASH? Industries 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of ASH? Industries 2019-2020

Table Form Technologies Company Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Form Technologies Company

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Form Technologies Company 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Form Technologies Company 2019-2020

Table Smith Metal Products Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Smith Metal Products

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Smith Metal Products 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Smith Metal Products 2019-2020

Table NetShape Technology Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of NetShape Technology

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of NetShape Technology 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of NetShape Technology 2019-2020

Table NIPPON PISTON RING Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of NIPPON PISTON RING

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of NIPPON PISTON RING 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of NIPPON PISTON RING 2019-2020

Table AMT Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of AMT

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of AMT 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of AMT 2019-2020

Table Dou Yee Technologies Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Dou Yee Technologies

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Dou Yee Technologies 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Dou Yee Technologies 2019-2020

Table Shin Zu Shing Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Shin Zu Shing

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Shin Zu Shing 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Shin Zu Shing 2019-2020

Table GIAN Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of GIAN

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of GIAN 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of GIAN 2019-2020

Table Future High-tech Information List

Figure Metal Injection Molding Parts (MIM Parts) Picture, Specifications and Applications of Future High-tech

Table Metal Injection Molding Parts (MIM Parts) Sales Volume, Price, Operating Cost, Operating Profits, Revenue (M USD) and Profits Margin of Future High-tech 2019-2020

Figure Metal Injection Molding Parts (MIM Parts) Sales Volume and World Market Share of Future High-tech 2019-2020

Table Business Locations

Figure Supply channels

Figure Marketing strategy

Table Barriers Analysis to Entry

Table Major Distributors and contact information by Regions

Table Major Customers and contact information by Regions

Table USA Supply, Import, Export, Consumption and Consumption Value(M USD)

Table Germany Supply, Import, Export, Consumption and Consumption Value(M USD)

Table China Supply, Import, Export, Consumption and Consumption Value(M USD)

Table Japan Supply, Import, Export, Consumption and Consumption Value(M USD)

Table India Supply, Import, Export, Consumption and Consumption Value(M USD)

Table World Demand by Regions Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Price by Regions Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Price by Types Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Price by Applications Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Revenue (M USD) by Regions Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Revenue (M USD) by Types Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

Table World Revenue (M USD) by Applications Forecast Analysis of Metal Injection Molding Parts (MIM Parts) (2020-2025)

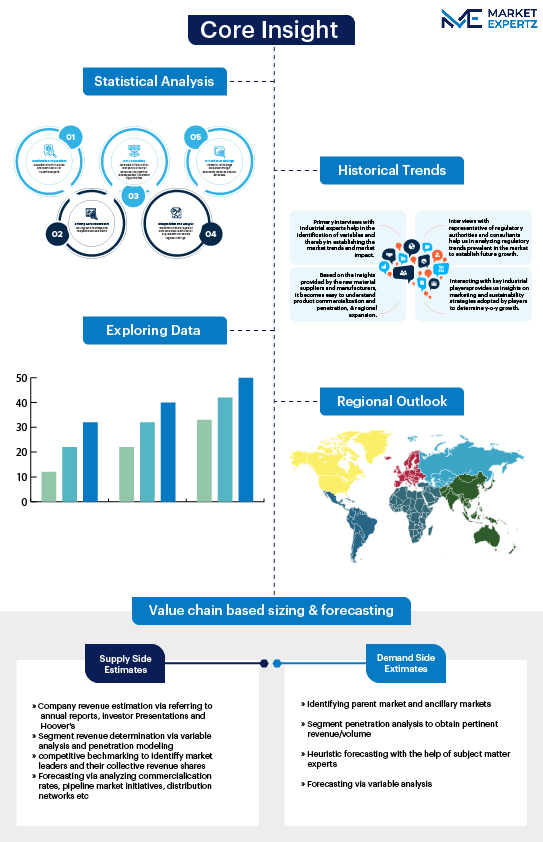

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"