Market Snapshot

| Study Period | 2019-2032 |

| Base Year | 2023 |

| Forcast Year | 2023-2032 |

| CAGR | 7.41 |

Gain accurate insights regarding the negative impacts of COVID-19 on all markets and industries

Download Sample PdfReport Overview

Tooling Composite Market Analysis Report 2023-2032:

The Tooling Composite Market size is estimated to grow at a CAGR of 5.67% between 2022 and 2032. The market size is forecast to increase by USD 1,876.45 million. The growth of the market depends on several factors, including the increasing demand for lightweight and high-performance materials in various industries, the growing adoption of composites in tooling applications, and the advancements in composite manufacturing technologies. Tooling composites are composite materials that are specifically designed and used for manufacturing molds, patterns, and tooling fixtures in industries such as aerospace, automotive, marine, and wind energy.

Tooling Composite Market Overview

Drivers

One of the key factors driving the Tooling Composite market growth is the increasing demand for lightweight and high-performance materials in various industries. With the growing emphasis on fuel efficiency, reduced emissions, and improved performance, industries such as aerospace and automotive are increasingly adopting lightweight materials to replace traditional metal tooling. Tooling composites offer excellent strength-to-weight ratio, high dimensional stability, and resistance to corrosion and chemicals, making them ideal for tooling applications. The use of tooling composites helps in reducing the weight of molds and fixtures, improving overall efficiency, and reducing production costs. Therefore, the increasing demand for lightweight and high-performance materials is expected to drive market growth during the forecast period.

Moreover, there is a growing adoption of composites in tooling applications due to their superior properties and advantages over traditional materials. Tooling composites offer excellent dimensional stability, high temperature resistance, low coefficient of thermal expansion, and good surface finish, making them suitable for complex and precise tooling applications. The use of composites in tooling helps in achieving higher accuracy, reducing lead times, and improving productivity. Industries such as aerospace, automotive, and wind energy are increasingly utilizing tooling composites to manufacture molds, patterns, and tooling fixtures. Hence, the growing adoption of composites in tooling applications is expected to drive market growth during the forecast period.

Trends

A key trend shaping the Tooling Composite market growth is the advancements in composite manufacturing technologies. With the continuous advancements in materials science and manufacturing processes, there have been significant developments in composite manufacturing technologies. Advanced manufacturing techniques such as automated fiber placement (AFP), resin transfer molding (RTM), and additive manufacturing (3D printing) have revolutionized the production of tooling composites. These technologies enable the production of complex and customized tooling components with high precision and efficiency. The advancements in composite manufacturing technologies have led to reduced production time, improved quality, and increased design flexibility, driving the adoption of tooling composites in various industries. Therefore, the advancements in composite manufacturing technologies are expected to fuel the demand for tooling composites during the forecast period.

Restraints:

One of the key challenges hindering the Tooling Composite market growth is the high cost of tooling composites compared to traditional materials. Tooling composites, especially advanced composites such as carbon fiber reinforced polymers (CFRP), are relatively expensive compared to metals and other conventional tooling materials. The high cost of tooling composites can pose a barrier to their widespread adoption, particularly in cost-sensitive industries. Additionally, the initial investment required for equipment and training for working with composites can be significant. Therefore, the high cost of tooling composites is expected to hinder market growth during the forecast period.

Furthermore, there are certain technical challenges associated with the use of tooling composites. Tooling composites require specialized knowledge and expertise for their design, fabrication, and maintenance. The complex nature of composite materials and the need for precise control of manufacturing processes can pose challenges for manufacturers. Moreover, composites are susceptible to damage from impact, abrasion, and exposure to harsh environments. Proper handling, maintenance, and repair of tooling composites are essential to ensure their longevity and performance. Therefore, the technical challenges associated with the use of tooling composites can limit their adoption and impact market growth during the forecast period.

Tooling Composite Market Segmentation By Application

The aerospace segment is estimated to witness significant growth during the forecast period. Tooling composites play a crucial role in the aerospace industry for manufacturing molds, patterns, and tooling fixtures used in the production of aircraft components. The aerospace industry requires high precision, complex geometries, and lightweight materials for tooling applications. Tooling composites offer the desired properties such as high strength, dimensional stability, and temperature resistance, making them suitable for aerospace tooling. The increasing demand for lightweight aircraft, advancements in aircraft manufacturing technologies, and the growing aerospace industry are driving the demand for tooling composites in the aerospace segment. Therefore, the aerospace segment is expected to fuel the growth of the Tooling Composite market during the forecast period.

Tooling Composite Market Segmentation By Type

The carbon fiber reinforced polymer (CFRP) segment is expected to dominate the market during the forecast period. CFRP composites offer excellent strength-to-weight ratio, high stiffness, and superior mechanical properties, making them ideal for tooling applications. CFRP composites provide high dimensional stability, low coefficient of thermal expansion, and resistance to chemicals and corrosion, ensuring the longevity and performance of tooling components. The aerospace, automotive, and wind energy industries are the major consumers of CFRP composites for tooling applications. The increasing demand for lightweight and high-performance tooling materials is driving the adoption of CFRP composites in various industries. Therefore, the CFRP segment is expected to drive the market growth during the forecast period.

Regional Overview

North America is estimated to contribute 38% to the growth of the global market during the forecast period. The region has a well-established aerospace industry, which is a major consumer of tooling composites. The increasing demand for lightweight aircraft, advancements in aircraft manufacturing technologies, and the presence of key aerospace manufacturers in North America are driving the demand for tooling composites in the region. Moreover, there is a growing adoption of composites in other industries such as automotive and wind energy, further fueling the demand for tooling composites. Therefore, North America is expected to be a key market for tooling composites during the forecast period.

In 2020, during the COVID-19 pandemic, the growth of the global tooling composite market witnessed a temporary slowdown due to disruptions in the supply chain and reduced demand from end-use industries. However, with the gradual recovery of the global economy and the resumption of industrial activities, the market is expected to recover and witness steady growth during the forecast period.

Tooling Composite Market Customer Landscape

The tooling composite market industry report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their growth strategies.

Who are the Major Tooling Composite Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Hexcel Corporation: The company offers tooling composite products such as HexTOOL® M61 and HexTOOL® M61H.

SGL Carbon SE: The company offers tooling composite products such as SIGRATHERM® HTW-1 and SIGRATHERM® HTW-2.

TenCate Advanced Composites: The company offers tooling composite products such as TC275-1 and TC275-1A.

The research report also includes detailed analyses of the competitive landscape of the market and information about 20 market companies, including:

Gurit Holding AG

Mitsubishi Chemical Corporation

Park Aerospace Corp.

Solvay SA

Teijin Limited

Toray Industries Inc.

Vectorply Corporation

Victrex plc

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Segment Overview

The tooling composite market report forecasts market growth by revenue at global, regional & country levels and provides an analysis of the latest trends and growth opportunities from 2019 to 2032.

Application Outlook (USD Million, 2019 - 2032)

Aerospace

Automotive

Marine

Wind Energy

Others

Type Outlook (USD Million, 2019 - 2032)

Carbon Fiber Reinforced Polymer (CFRP)

Glass Fiber Reinforced Polymer (GFRP)

Others

Geography Outlook (USD Million, 2019 - 2032)

North America

The U.S.

Canada

Europe

U.K.

Germany

France

Rest of Europe

APAC

China

India

South America

Chile

Argentina

Brazil

Middle East & Africa

Saudi Arabia

South Africa

Rest of the Middle East & Africa

Table of Contents

1 Report Overview

1.1 Definition

1.2 Manufacturers and Regions Overview

1.2.1 Manufacturers Overview

1.2.2 Regions Overview

1.3 Type Overview

1.4 Application Overview

1.5 Industrial Chain

1.5.1 Tooling Composite Overall Industrial Chain

1.5.2 Upstream

1.5.3 Downstream

1.5.4 Economic/Political Environment

2 Global Tooling Composite Market Assesment by Types

2.1 Overall Market Performance

2.1.1 Product Type Market Performance (Volume)

2.1.2 Product Type Market Performance (Value)

2.2 China Tooling Composite Market Performance

2.3 USA Tooling Composite Market Performance

2.4 Europe Tooling Composite Market Performance

2.5 Japan Tooling Composite Market Performance

2.6 Korea Tooling Composite Market Performance

2.7 India Tooling Composite Market Performance

2.8 Southeast Asia Tooling Composite Market Performance

2.9 South America Tooling Composite Market Performance

3 Global Tooling Composite Market Assesment by Application

3.1 Overall Market Performance (Volume)

3.2 China Tooling Composite Market Performance (Volume)

3.3 USA Tooling Composite Market Performance (Volume)

3.4 Europe Tooling Composite Market Performance (Volume)

3.5 Japan Tooling Composite Market Performance (Volume)

3.6 Korea Tooling Composite Market Performance (Volume)

3.7 India Tooling Composite Market Performance (Volume)

3.8 Southeast Asia Tooling Composite Market Performance (Volume)

3.9 South America Tooling Composite Market Performance (Volume)

4 Competitive Analysis

4.1 Cytec

4.1.1 Cytec Profiles

4.1.2 Cytec Product Information

4.1.3 Cytec Tooling Composite Production, Revenue, Price and Gross Margin

4.1.4 Cytec Tooling Composite Business Performance

4.1.5 SWOT Analysis

4.2 Hexcel

4.2.1 Hexcel Profiles

4.2.2 Hexcel Product Information

4.2.3 Hexcel Tooling Composite Production, Revenue, Price and Gross Margin

4.2.4 Hexcel Tooling Composite Business Performance

4.2.5 SWOT Analysis

4.3 TenCate

4.3.1 TenCate Profiles

4.3.2 TenCate Product Information

4.3.3 TenCate Tooling Composite Production, Revenue, Price and Gross Margin

4.3.4 TenCate Tooling Composite Business Performance

4.3.5 SWOT Analysis

4.4 Sika AG

4.4.1 Sika AG Profiles

4.4.2 Sika AG Product Information

4.4.3 Sika AG Tooling Composite Production, Revenue, Price and Gross Margin

4.4.4 Sika AG Tooling Composite Business Performance

4.4.5 SWOT Analysis

4.5 DuPont

4.5.1 DuPont Profiles

4.5.2 DuPont Product Information

4.5.3 DuPont Tooling Composite Production, Revenue, Price and Gross Margin

4.5.4 DuPont Tooling Composite Business Performance

4.5.5 SWOT Analysis

4.6 Airtech International

4.6.1 Airtech International Profiles

4.6.2 Airtech International Product Information

4.6.3 Airtech International Tooling Composite Production, Revenue, Price and Gross Margin

4.6.4 Airtech International Tooling Composite Business Performance

4.6.5 SWOT Analysis

4.7 Gurit

4.7.1 Gurit Profiles

4.7.2 Gurit Product Information

4.7.3 Gurit Tooling Composite Production, Revenue, Price and Gross Margin

4.7.4 Gurit Tooling Composite Business Performance

4.7.5 SWOT Analysis

4.8 Teijin

4.8.1 Teijin Profiles

4.8.2 Teijin Product Information

4.8.3 Teijin Tooling Composite Production, Revenue, Price and Gross Margin

4.8.4 Teijin Tooling Composite Business Performance

4.8.5 SWOT Analysis

4.9 Celanese

4.9.1 Celanese Profiles

4.9.2 Celanese Product Information

4.9.3 Celanese Tooling Composite Production, Revenue, Price and Gross Margin

4.9.4 Celanese Tooling Composite Business Performance

4.9.5 SWOT Analysis

4.10 BASF

4.10.1 BASF Profiles

4.10.2 BASF Product Information

4.10.3 BASF Tooling Composite Production, Revenue, Price and Gross Margin

4.10.4 BASF Tooling Composite Business Performance

4.10.5 SWOT Analysis

4.11 SGL Group

4.12 PRF Composite Materials

5 Competitive Landscape

5.1 Global Tooling Composite Production (K Units) and Market Share by Manufacturers (2014-2020)

5.2 Global Tooling Composite Revenue (M USD) and Market Share by Manufacturers (2014-2020)

5.3 Global Tooling Composite Price (USD/Unit) of Manufacturers (2014-2020)

5.4 Global Tooling Composite Gross Margin of Manufacturers (2014-2020)

5.5 Market Concentration

6 Global Tooling Composite Market Assessment by Regions

6.1 Global Tooling Composite Production (K Units) and Market Share by Regions (2014-2020)

6.2 Global Tooling Composite Revenue (M USD) and Market Share by Regions (2014-2020)

6.3 Global Tooling Composite Price (USD/Unit) by Regions (2014-2020)

6.4 Global Tooling Composite Gross Margin by Regions (2014-2020)

7 Tooling Composite Regional Analysis

7.1 China Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.2 USA Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.3 Europe Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.4 Japan Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.5 Korea Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.6 India Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.7 Southeast Asia Tooling Composite Production, Revenue and Growth Rate (2014-2020)

7.8 South America Tooling Composite Production, Revenue and Growth Rate (2014-2020)

8 Global Tooling Composite Consumption Assessment

8.1 Global Tooling Composite Consumption and Market Share by Regions (2014-2020)

8.2 Global Tooling Composite Consumption Value and Market Share by Regions (2014-2020)

8.3 Global Tooling Composite Average Price (USD/Unit) by Regions (2014-2020)

9 Global Tooling Composite Sales Assessment by Regions

9.1 Global Tooling Composite Sales and Sales Value (2014-2020)

9.2 China Tooling Composite Sales and Sales Value (2014-2020)

9.3 USA Tooling Composite Sales and Sales Value (2014-2020)

9.4 Europe Tooling Composite Sales and Sales Value (2014-2020)

9.5 Japan Tooling Composite Sales and Sales Value (2014-2020)

9.6 Korea Tooling Composite Sales and Sales Value (2014-2020)

9.7 India Tooling Composite Sales and Sales Value (2014-2020)

9.8 Southeast Asia Tooling Composite Sales and Sales Value (2014-2020)

9.9 South America Tooling Composite Sales and Sales Value (2014-2020)

10 Technology and Cost

10.1 Technology

10.2 Cost

11 Channel Analysis

11.1 Market Channel

11.2 Distributors

12 Market Forecast 2021-2026

12.1 Production and Revenue Forecast 2021-2026

12.1.1 Global Tooling Composite Production and Revenue by Regions 2021-2026

12.1.2 China Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.3 USA Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.4 Europe Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.5 Japan Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.6 Korea Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.7 India Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.8 Southeast Asia Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.1.9 South America Tooling Composite Production, Revenue and Growth Rate 2021-2026

12.2 Sales and Sales Value Forecast 2021-2026

12.2.1 Global Tooling Composite Consumption and Consumption Calue by Regions 2021-2026

12.2.2 Global Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.3 China Tooling Composite Sales, Sales Value and Growth Rate 2021-2026

12.2.4 USA Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.5 Europe Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.6 Japan Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.7 Korea Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.8 India Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.9 Southeast Asia Tooling Composite Sales and Sales Value Forecast 2021-2026

12.2.10 South America Tooling Composite Sales and Sales Value Forecast 2021-2026

12.3 Global Tooling Composite Production and Revenue Forecast by Type 2021-2026

12.3.1 Overall Market Performance

12.3.2 Epoxy Resin

12.3.3 BMI

12.3.4 Others

12.4 Global Tooling Composite Sales Forecast by Application 2021-2026

12.4.1 Overall Market Performance

12.4.2 Transportation

12.4.3 Marine

12.4.4 Wind Energy

12.4.5 Aerospace

12.4.6 Other

12.5 Global Tooling Composite Price and Gross Margin Forecast

13.5.1 Global Tooling Composite Averages Price Development Trend Forecast 2021-2026

13.5.2 Global Tooling Composite Gross Margin Development Trend Forecast 2021-2026

13 Conclusion

List of Tables and Figures

Figure Product Picture of Tooling Composite

Table Manufacturers List in the Report

Table Manufacturers Production Market Share (%) (2018-2020)

Table Production Market Share (%) by Regions in (2018-2020)

Table Production Market Share (%) by Type in (2018-2020)

Figure Epoxy Resin Product Picture

Table Major Manufacturers of Epoxy Resin

Figure BMI Product Picture

Table Major Manufacturers of BMI

Figure Others Product Picture

Table Major Manufacturers of Others

Table Production Market Share (%) by Application in (2018-2020)

Figure Transportation Examples

Table Key Downstream Customer in Transportation

Figure Marine Examples

Table Key Downstream Customer in Marine

Figure Wind Energy Examples

Table Key Downstream Customer in Wind Energy

Figure Aerospace Examples

Table Key Downstream Customer in Aerospace

Figure Other Examples

Table Key Downstream Customer in Other

Figure Industry Chain Structure of Tooling Composite

Table Key Suppliers of Raw Material/Components

Repereentative Downstream Enterprise of Tooling Composite

Table Global Tooling Composite Production (K Units) by Type

Figure Global Tooling Composite Production Market Share (%) Comparison by Types in 2014 and 2020

Table Production (K Units) and Growth Rate (2014-2020)

Figure Production (K Units) and Growth Rate (2014-2020)

Table Production (K Units) and Growth Rate (2014-2020)

Figure Production (K Units) and Growth Rate (2014-2020)

Table Production (K Units) and Growth Rate (2014-2020)

Figure Production (K Units) and Growth Rate (2014-2020)

Table Global Tooling Composite Revenue (M USD) by Type

Figure Global Tooling Composite Revenue Market Share (%) Comparison by Types in 2014 and 2020

Table Revenue (M USD) and Growth Rate (2014-2020)

Figure Revenue (M USD) and Growth Rate (2014-2020)

Table Revenue (M USD) and Growth Rate (2014-2020)

Figure Revenue (M USD) and Growth Rate (2014-2020)

Table Revenue (M USD) and Growth Rate (2014-2020)

Figure Revenue (M USD) and Growth Rate (2014-2020)

Table China Tooling Composite Production (K Units) by Type in (2014-2020)

Figure China Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table China Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure China Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table USA Tooling Composite Production (K Units) by Type in (2014-2020)

Figure USA Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table USA Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure USA Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table Europe Tooling Composite Production (K Units) by Type in (2014-2020)

Figure Europe Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table Europe Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure Europe Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table Japan Tooling Composite Production (K Units) by Type in (2014-2020)

Figure Japan Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table Japan Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure Japan Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table Korea Tooling Composite Production (K Units) by Type in (2014-2020)

Figure Korea Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table Korea Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure Korea Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table India Tooling Composite Production (K Units) by Type in (2014-2020)

Figure India Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table India Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure India Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table Southeast Asia Tooling Composite Production (K Units) by Type in (2014-2020)

Figure Southeast Asia Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table Southeast Asia Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure Southeast Asia Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table South America Tooling Composite Production (K Units) by Type in (2014-2020)

Figure South America Tooling Composite Production Market Share (%) Comparison by Type in 2014 and 2020

Table South America Tooling Composite Revenue (M USD) by Type in (2014-2020)

Figure South America Tooling Composite Revenue (M USD) Market Share (%) Comparison by Type in 2014 and 2020

Table Global Tooling Composite Sales (K Units) by Application (2014-2020)

Figure Global Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Sales (K Units) and Growth Rate (2014-2020)

Figure Sales (K Units) and Growth Rate (2014-2020)

Table Sales (K Units) and Growth Rate (2014-2020)

Figure Sales (K Units) and Growth Rate (2014-2020)

Table Sales (K Units) and Growth Rate (2014-2020)

Figure Sales (K Units) and Growth Rate (2014-2020)

Table Sales (K Units) and Growth Rate (2014-2020)

Figure Sales (K Units) and Growth Rate (2014-2020)

Table Sales (K Units) and Growth Rate (2014-2020)

Figure Sales (K Units) and Growth Rate (2014-2020)

Table China Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure China Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table USA Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure USA Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Europe Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure Europe Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Japan Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure Japan Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Korea Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure Korea Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table India Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure India Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Southeast Asia Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure Southeast Asia Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table South America Tooling Composite Sales (K Units) by Application in ( (2014-2020))

Figure South America Tooling Composite Sales Market Share (%) Comparison by Application in 2014 and 2020

Table Cytec Profiles

Table Cytec Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Cytec Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Hexcel Profiles

Table Hexcel Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Hexcel Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table TenCate Profiles

Table TenCate Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure TenCate Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Sika AG Profiles

Table Sika AG Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Sika AG Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Sika AG Profiles

Table Sika AG Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Sika AG Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table DuPont Profiles

Table DuPont Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure DuPont Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Airtech International Profiles

Table Airtech International Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Airtech International Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Gurit Profiles

Table Gurit Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Gurit Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Teijin Profiles

Table Teijin Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Teijin Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Teijin Profiles

Table Celanese Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure Celanese Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table BASF Profiles

Table BASF Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure BASF Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table SGL Group Profiles

Table SGL Group Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure SGL Group Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table PRF Composite Materials Profiles

Table PRF Composite Materials Tooling Composite Production (K Units), Revenue (M USD), Price (USD/Unit), Cost (USD/Unit) and Gross Profit (2014-2020)

Figure PRF Composite Materials Tooling Composite Production and Growth Rate (2014-2020)

Figure SWOT Analysis

Table Global Tooling Composite Production (K Units) of Manufacturers (2014-2020)

Figure Global Tooling Composite Production Market Share (%) of Manufacturers in (2014-2020)

Figure Global Tooling Composite Production Market Share (%) Comparison of Manufacturers in 2014 and 2020

Table Global Tooling Composite Revenue (M USD) of Manufacturers (2014-2020)

Figure Global Tooling Composite Revenue Market Share (%) of Manufacturers in (2014-2020)

Figure Global Tooling Composite Revenue Market Share (%) Comparison of Manufacturers in 2014 and 2020

Figure Global Tooling Composite Price (USD/Unit) of Manufacturers in (2014-2020)

Figure Global Tooling Composite Price Comparison of Manufacturers in 2014 and 2020

Table Global Tooling Composite Gross Margin of Manufacturers (2014-2020)

Figure Global Tooling Composite Gross Margin Comparison of Manufacturers in 2014 and 2020

Figure Global Tooling Composite Market Concentration (2014-2020)

Table Top 3 Production Market Share (%) (2014-2020)

Table Top 5 Production Market Share (%) (2014-2020)

Table Top 8 Production Market Share (%) (2014-2020)

Table Global Tooling Composite Production (K Units) by Regions (2014-2020)

Figure Global Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Table Global Tooling Composite Production Market Share (%) by Regions in (2014-2020)

Figure Global Tooling Composite Production Market Share (%) Comparison by Regions in 2014 and 2020

Table Global Tooling Composite Revenue (M USD) by Regions (2014-2020)

Figure Global Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Table Global Tooling Composite Revenue Market Share (%) by Regions in (2014-2020)

Figure Global Tooling Composite Revenue Market Share (%) Comparison by Regions in 2014 and 2020

Table Global Tooling Composite Price (USD/Unit) by Regions (2014-2020)

Figure Global Tooling Composite Average Price (USD/Unit) Comparison by Regions in 2014 and 2020

Table Global Tooling Composite Gross Margin by Regions (2014-2020)

Figure Global Tooling Composite Gross Margin Comparison by Regions in 2014 and 2020

Figure China Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure China Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure USA Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure USA Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure Europe Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure Europe Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure Japan Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure Japan Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure Korea Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure Korea Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure India Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure India Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure Southeast Asia Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure Southeast Asia Tooling Composite Revenue (M USD) and Growth Rate (2014-2020)

Figure South America Tooling Composite Production (K Units) and Growth Rate (2014-2020)

Figure South AmericaTooling CompositeRevenue (M USD) and Growth Rate (2014-2020)

Table Global Tooling Composite Consumption by Regions (2014-2020)

Table Global Tooling Composite Consumption Market Share (%) by Regions (2014-2020)

Figure Global Tooling Composite Consumption Market Share (%) Comparison by Regions in 2014 and 2020

Table Global Tooling Composite Consumption Value by Regions (2014-2020)

Table Global Tooling Composite Consumption Value Market Share (%) by Regions (2014-2020)

Figure Global Tooling Composite Consumption Value Market Share (%) Comparison by Regions in 2014 and 2020

Table Global Tooling Composite Average Price (USD/Unit) by Regions (2014-2020)

Figure Global Tooling Composite Average Price (USD/Unit) Comparison by Regions in 2014 and 2020

Figure Global Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure Global Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure China Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure China Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure USA Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure USA Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure Europe Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure Europe Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure Japan Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure Japan Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure Korea Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure Korea Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure India Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure India Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure Southeast Asia Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure Southeast Asia Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Figure South America Tooling Composite Sales (K Units) and Growth Rate (2014-2020)

Figure South America Tooling Composite Sales Value (M USD) and Growth Rate (2014-2020)

Table Manufacture Technology of Tooling Composite

Figure Cost Structure of Tooling Composite in 2020

Distributors/Traders List

Table Global Tooling Composite Production (K Units) by Regions 2021-2026

Figure Global Tooling Composite Production and Growth Rate 2021-2026

Table Global Tooling Composite Production Market Share (%) by Regions 2021-2026

Figure Global Tooling Composite Production Market Share (%) Comparison by Regions in 2020 and 2025

Table Global Tooling Composite Revenue (M USD) by Regions 2021-2026

Table Global Tooling Composite Revenue and Growth Rate 2021-2026

Figure Global Tooling Composite Revenue Market Share (%) by Regions 2021-2026

Figure Global Tooling Composite Revenue Market Share (%) Comparison by Regions in 2020 and 2025

Figure China Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure China Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure USA Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure USA Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure Europe Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure Europe Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure Japan Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure Japan Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure Korea Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure Korea Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure India Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure India Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure Southeast Asia Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure Southeast Asia Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Figure South America Tooling Composite Production (K Units) and Growth Rate 2021-2026

Figure South America Tooling Composite Revenue (M USD) and Growth Rate 2021-2026

Table Global Tooling Composite Consumption by Regions 2021-2026

Table Global Tooling Composite Consumption Market Share (%) by Regions 2021-2026

Figure Global Tooling Composite Consumption Market Share (%) Comparison by Regions in 2020 and 2025

Table Global Tooling Composite Consumption Value by Regions 2021-2026

Table Global Tooling Composite Consumption Value Market Share (%) by Regions 2021-2026

Figure Global Tooling Composite Consumption Value Market Share (%) Comparison by Regions in 2020 and 2025

Figure Global Tooling Composite Sales and Growth Rate 2021-2026

Figure Global Tooling Composite Sales Value and Growth Rate 2021-2026

Figure China Tooling Composite Sales and Growth Rate 2021-2026

Figure China Tooling Composite Sales Value and Growth Rate 2021-2026

Figure USA Tooling Composite Sales and Growth Rate 2021-2026

Figure USA Tooling Composite Sales Value and Growth Rate 2021-2026

Figure Europe Tooling Composite Sales and Growth Rate 2021-2026

Figure Europe Tooling Composite Sales Value and Growth Rate 2021-2026

Figure Japan Tooling Composite Sales and Growth Rate 2021-2026

Figure Japan Tooling Composite Sales Value and Growth Rate 2021-2026

Figure Korea Tooling Composite Sales and Growth Rate 2021-2026

Figure Korea Tooling Composite Sales Value and Growth Rate 2021-2026

Figure India Tooling Composite Sales and Growth Rate 2021-2026

Figure India Tooling Composite Sales Value and Growth Rate 2021-2026

Figure Southeast Asia Tooling Composite Sales and Growth Rate 2021-2026

Figure Southeast Asia Tooling Composite Sales Value and Growth Rate 2021-2026

Figure South America Tooling Composite Sales and Growth Rate 2021-2026

Figure South America Tooling Composite Sales Value and Growth Rate 2021-2026

Table Global Tooling Composite Production (K Units) by Type 2021-2026

Figure Global Tooling Composite Production Market Share (%) Comparison by Types in 2020 and 2025

Figure Production (K Units) and Growth Rate

Figure Revenue (M USD) and Growth Rate

Figure Production (K Units) and Growth Rate

Figure Revenue (M USD) and Growth Rate

Figure Production (K Units) and Growth Rate

Figure Revenue (M USD) and Growth Rate

Table Global Tooling Composite Sales (M USD) by Application 2021-2026

Figure Global Tooling Composite Sales Market Share (%) Comparison by Application in 2020 and 2025

Figure Sales (M USD) and Growth Rate

Figure Sales (M USD) and Growth Rate

Figure Sales (M USD) and Growth Rate

Figure Sales (M USD) and Growth Rate

Figure Sales (M USD) and Growth Rate

Table Global Tooling Composite Average Price (USD/Unit) Forecast 2021-2026

Table Global Tooling Composite Gross Margin Forecast 2021-2026

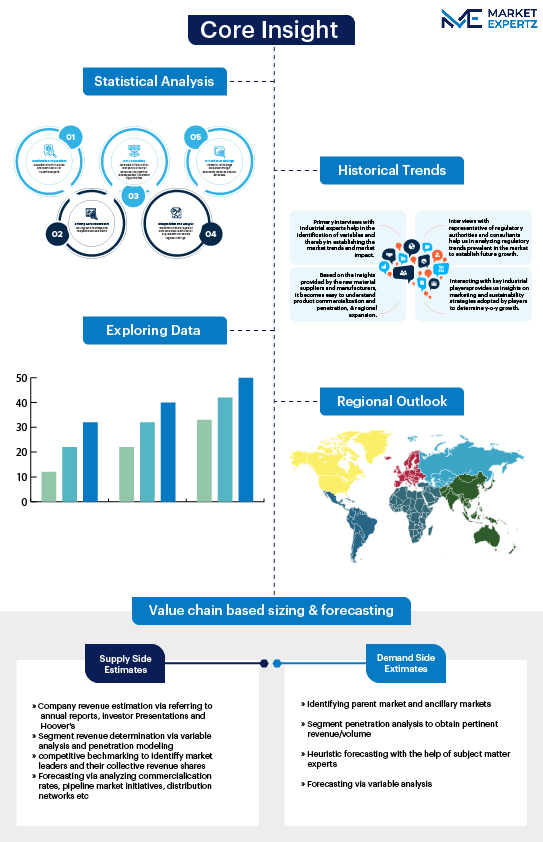

RESEARCH METHODOLOGY

A research methodology is a systematic approach for assessing or conducting a market study. Researchers tend to draw on a variety of both qualitative and quantitative study methods, inclusive of investigations, survey, secondary data and market observation.

Such plans can focus on classifying the products offered by leading market players or simply use statistical models to interpret observations or test hypotheses. While some methods aim for a detailed description of the factors behind an observation, others present the context of the current market scenario.

Now let’s take a closer look at the research methods here.

Secondary Research Model

Extensive data is obtained and cumulated on a substantial basis during the inception phase of the research process. The data accumulated is consistently filtered through validation from the in-house database, paid sources as well reputable industry magazines. A robust research study requires an understanding of the overall value chain. Annual reports and financials of industry players are studied thoroughly to have a comprehensive idea of the market taxonomy.

Primary Insights

Post conglomeration of the data obtained through secondary research; a validation process is initiated to verify the numbers or figures. This process is usually performed by having a detailed discussion with the industry experts.

However, we do not restrict our primary interviews only to the industry leaders. Our team covers the entire value chain while verifying the data. A significant number of raw material suppliers, local manufacturers, distributors, and stakeholders are interviewed to make our findings authentic. The current trends which include the drivers, restraints, and opportunities are also derived through the primary research process.

Market Estimation

The market estimation is conducted by analyzing the data collected through both secondary and primary research. This process involves market breakdown, bottom-up and top- down approach.

Moreover, while forecasting the market a comprehensive statistical time series model is designed for each market. Macroeconomic indicators are considered to understand the current trends of the market. Each data point is verified by the process of data triangulation method to arrive at the final market estimates.

Final Presentation

The penultimate process results in a holistic research report. The study equips key industry players to undertake significant strategic decisions through the findings. The report encompasses detailed market information. Graphical representations of the current market trends are also made available in order to make the study highly comprehensible for the reader.

Personalized Business Report Tailored to Your Requirements

- Our expert analysts collaborate directly with you to comprehend your specific needs.

- Get data on regions, segments, competitors, and vendors of your choice.

- Information is presented in alignment with your exact preferences and formatting.

Free Sample Report

"Find new revenue generation opportunities"